Reelmaster 2300–D/2600–DHydraulic System Page 4 – 76

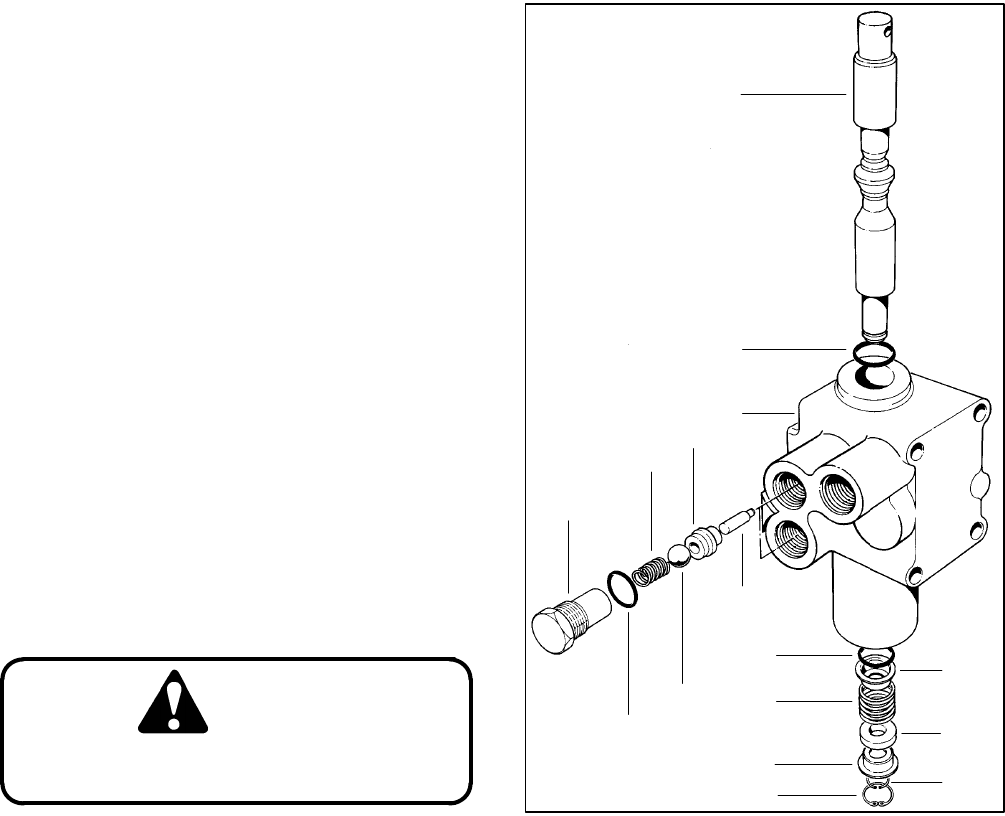

Control Valve Disassembly (Fig. 66)

1. Wash control valve in solvent and dry it thoroughly.

2. Mount control valve into a vise so the mounting pads

are against the jaws of the vice and snap ring (14) faces

up.

Note: Remove check valve seat (5) only if it needs re-

placement; it is press fitted in.

3. Remove plug (1) and O–ring (2) from the valve body

(7). Remove spring (3), ball (4), cam pin (6).

4. Repeat step 3 for the other plug (1).

5. Remove snap ring (14) from the bottom of the valve

body (7). Remove spool snap ring (13), spring retainer

(10), spacer (12), and spring (11).

6. Push and twist spool (8) carefully out of the valve

body (7). Set spool aside.

7. Remove O–rings (9) using a soft hooked scribe or

a thin screwdriver and being careful not to scratch the

valve bore finish.

Control Valve Inspection (Fig. 66)

CAUTION

Use eye protection such as goggles when

using compressed air

1. Wash all parts in solvent. Dry parts with compressed

air.

2. Inspect spool (8) for bending and flatness. Signs of

wear on one side of the spool may indicate it’s bent. Re-

place a worn or damaged spool if necessary.

3. Inspect parts for wear or damage, and replace if

necessary.

Control Valve Reassembly (Fig. 66)

1. Coat all new O–rings with hydraulic oil. Install new

O–rings (9) into the bore of the valve body (7).

2. Coat spool (8) lightly with hydraulic oil. Push and

twist spool carefully into the valve body (7). Avoid dam-

aging O–rings (9).

1. Plug

2. O–ring

3. Spring

4. Ball

5. Check valve seat

6. Cam pin

7. Body

8. Spool

9. O–ring

10. Spring retainer

11. Spring

12. Spacer

13. Spool snap ring

14. Snap ring

Figure 66

10

12

13

14

10

11

9

8

9

7

6

4

2

1

3

5

3. Install spring retainer (10), spring (11), spacer (12),

other spring retainer (10), and spool snap ring (13) onto

the spool (8). Install snap ring (14) into the valve body

(7).

4. If check valve seat (5) was damaged and removed,

press fit it into the valve body (7).

5. Install cam pin (6), ball (4), and spring (3). Place new

O–ring (2) on plug (1) and install them into the valve

body (7). Tighten plug (1).

6. Repeat steps 4 and 5 for the other plug (1) and valve

assembly.