Reelmaster 2300–D/2600–DHydraulic System Page 4 – 70

Inspection (Fig. 60)

CAUTION

Use eye protection such as goggles when

using compressed air

1. Wash all parts in solvent. Dry parts with compressed

air.

2. Inspect internal surface of barrel (11) for deep

scratches, out–of–roundness, and bending. Replace if

worn or damaged.

3. Inspect head (3), shaft (6), and piston (8) for exces-

sive pitting, scoring, and wear. Replace any worn or

damaged parts.

Reassembly (Fig. 60)

1. Coat all O–rings, uni–ring, and backup washer light-

ly with hydraulic oil. Install new O–ring (7) and uni–ring

(9) to the piston (8). Install O–rings (2 and 5) and backup

washer (4) to the head (3).

IMPORTANT: Do not clamp vise jaws against shaft

(6) surface. Protect shaft surface before mounting

in the vise.

2. Mount shaft (6) securely in a vise by clamping vise

on the ends of the shaft. Slide head (3) onto the shaft.

Install piston (8) and locknut (10) onto the shaft and

tighten lock nut (10).

3. Remove shaft (6) from the vise.

IMPORTANT: Prevent damage when clamping the

barrel (11) into a vise; clamp on the pivot end only.

Do not close vise enough to distort barrel.

4. Mount barrel (11) in a vise so that the shaft end tilts

up slightly.

5. Coat all internal lift cylinder parts with a light coat of

hydraulic oil. Slide piston (8), shaft (6), and head (3) as-

sembly into barrel (11) being careful not to damage the

seals.

6. Secure head (3) in barrel (11) by installing retaining

ring (1). Align key slot in head with the access groove in

the barrel. Rotate head clockwise as far as the retaining

ring will allow. The offset end of the retaining ring will be

against the left side of the barrel groove as shown in Fig-

ure 62.

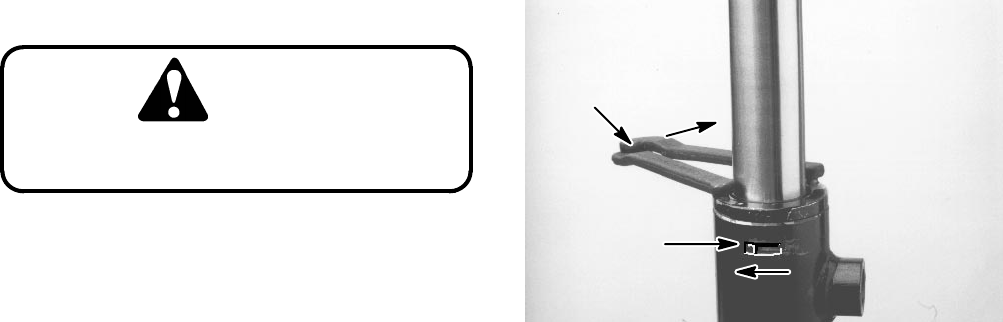

Figure 62

Spanner

wrench

Retaining ring

(Offset end

against left side of

barrel groove

after installing)

Installing retaining ring