Reelmaster 2300–D/2600–D

Page 3 – 8

Engine

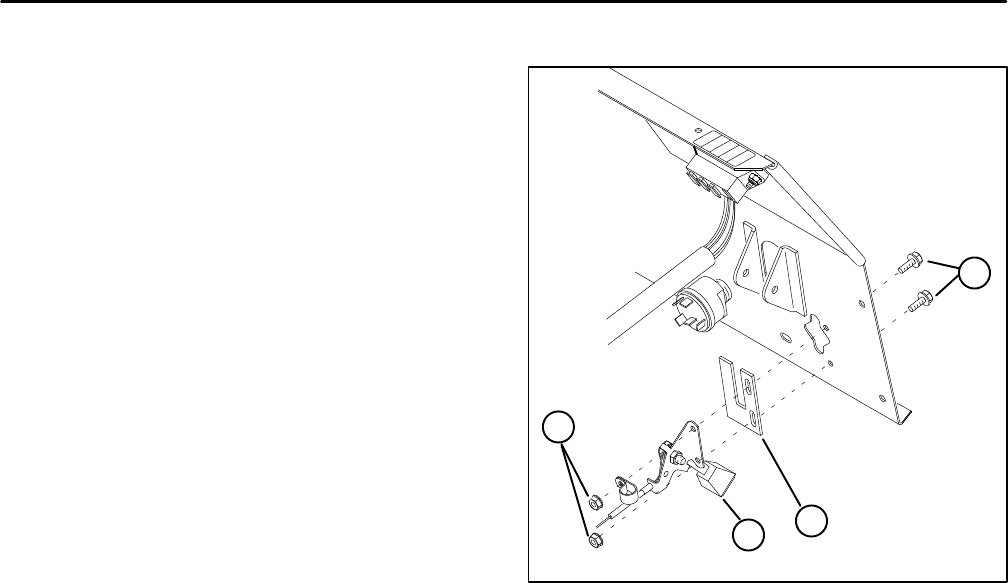

Throttle Linkage

1. Verify high engine speed at 3200 50 RPM with

the cold start button depressed.

2. If engine speed is out of specification, loosen cap

screw, nut, and throttle cable clamp on the throttle cable

bracket enough to allow the cable to slide freely within

the bracket.

3. Move throttle lever up fully to the high speed posi-

tion.

4. Pull cable toward flywheel end of the engine until the

governor lever on the engine is up against the high

speed adjustment screw. Tighten cap screw and nut se-

curing the throttle cable clamp.

5. Loosen capscrews (1) and nuts (2) securing the

throttle stop (3).

6. With the cold start button depressed, carefully ad-

just low engine speed to 1400 50 RPM with the

throttle control lever (4); adjust low speed stop screw

if necessary.

7. Make sure throttle control lever (4) is down so the

governor lever on the engine touches the low speed ad-

justment screw.

8. Adjust throttle stop (3) until it contacts the bottom of

the throttle control lever (4). Tighten cap screws (1) and

nuts (2) securing the throttle stop.

9. Make sure governor lever on the engine goes

against the high speed adjustment screw when the

throttle control lever (4) is moved to the high speed posi-

tion. When the throttle control lever is moved to the low

speed position, the governor lever on the engine should

contact the low speed adjustment screw at the same

time the throttle control lever contacts the throttle stop

(3).

Figure 9

1. Cap screw

2. Nut

3. Throttle stop

4. Throttle control lev

e

1

3

4

2