Reelmaster 2300–D/2600–D

Page 5 – 18

Electrical System

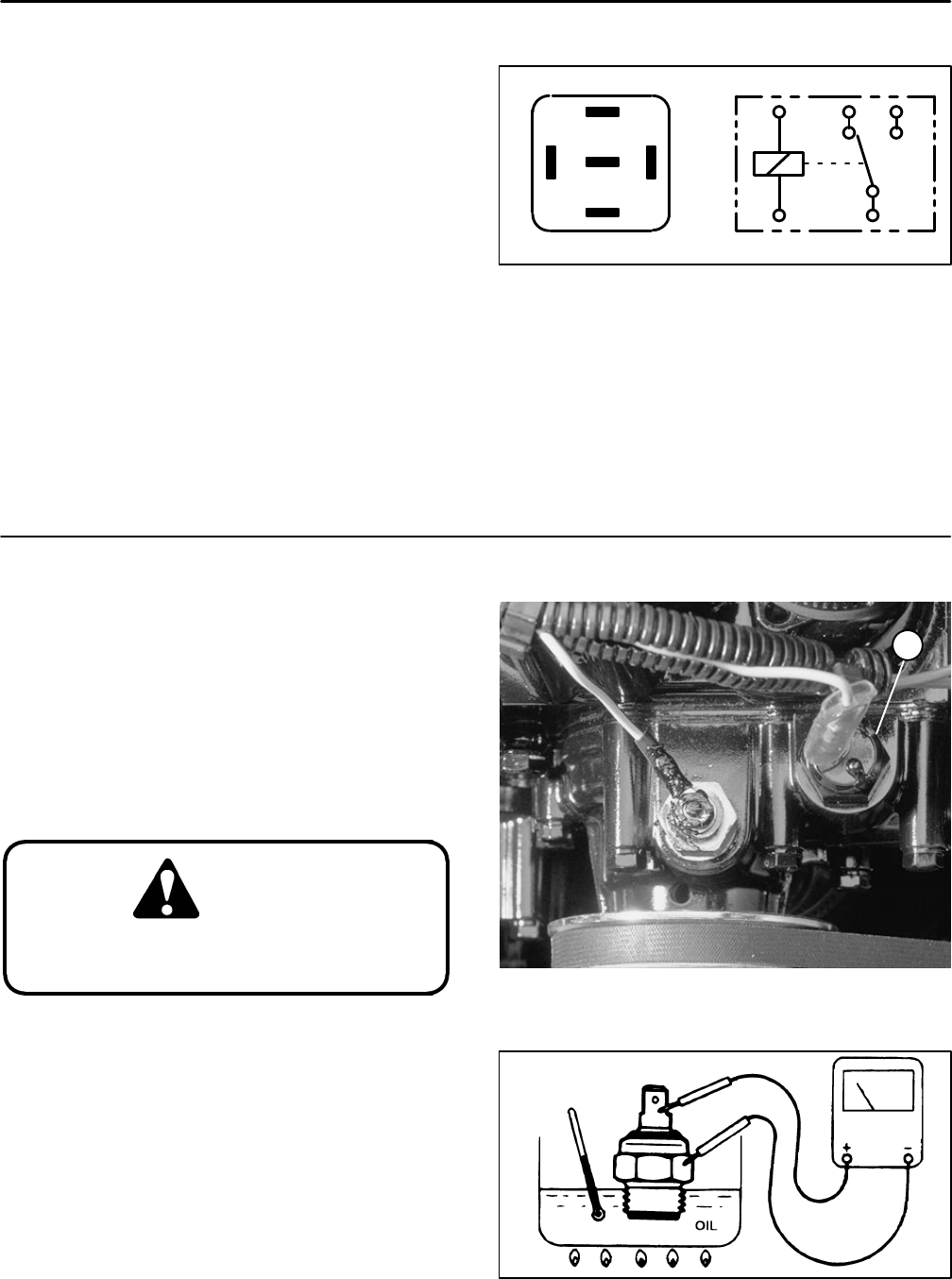

Starter and High Temperature Shut Down Relays

1. Verify coil resistance between terminals 86 and 85

with a multimeter (ohms setting). Resistance should be

from 80 to 90 ohms.

2. Connect multimeter (ohms setting) leads to relay

terminals 30 and 87. Ground terminal 86 and apply +12

VDC to terminal 85. The relay should make and break

continuity between terminals 30 and 87 as 12 VDC is ap-

plied and removed from terminal 85.

3. Disconnect voltage from terminal 85 and multimeter

lead from terminal 87.

4. Connect multimeter (ohms setting) lead to relay ter-

minal 30 and 87A. Apply +12 VDC to terminal 85. The

relay should break and make continuity between termi-

nals 30 and 87A as 12 VDC is applied and removed from

terminal 85.

5. Disconnect voltage from and multimeter leads from

relay terminals.

Figure 4

87A

30

87

86 85

85

86 87A 87

30

High Temperature Shutdown Switch

The switch is located on top of the water pump. The

pump is on the left end of the engine inside of the fan

pulley assembly. There is a tan wire attached to the

switch.

1. Lower the coolant level in the engine and remove

the high temperature shutdown switch.

2. Put the switch in a container of oil with a thermome-

ter and slowly heat the oil (Fig. 6).

CAUTION

Handle the hot oil with extreme care to

prevent personal injury or fire.

3. Check the continuity of the switch with a multimeter

(ohms setting). The switch is normally open and should

close at 206 to 218_F (97 to 103_C).

4. Allow the oil to cool. The switch should open at

194_F (90_C).

1. High temperature shutdown switch

Figure 5

1

Figure 6