Reelmaster 2300–D/2600–DPage 7 – 8Cutting Units

Height–of–Cut and Leveling Rear Roller

Note: Both floating and fixed cutting units can use this

method for making height of cut adjustments and level-

ing both front and back rollers.

1. Position cutting unit on a flat level table or board.

2. Slightly loosen (crack) nut securing each roller

bracket to the angle bracket.

3. For the rear roller, adjust support cap screw to

achieve 5/8” +

1/16 (15.9 mm "1.6) dimension between

both Height–of–Cut supports and rear

roller brackets.

4. For the front roller, adjust support cap screw to

achieve 1” +

1/16 (25.4 mm "1.6) dimension between

both Height–of–Cut supports and

front

roller brackets.

5. For the rear roller, remove hairpin cotters securing

rear

Height–of–Cut pins and reinstall in the 1/2” setting

as indicated on the rear Height–of–Cut plate.

6. For the front roller, remove hairpin cotters securing

front Height–of–Cut pins and reinstall in the 1/4” setting

as indicated on the front Height–of–Cut plate to allow

clearance between front roller and table.

7. Position a 1/2” or thicker bar under the reel blades

and against the front face of the bedknife. Make sure bar

covers the full length of reel blades.

8. Verify that rear roller is level, by attempting to insert

a piece of paper under each end of roller. The paper

should not fit between the roller and the table.

9. Level rear roller by adjusting the appropriate sup-

port cap screw on rear roller supports until the roller is

parallel and the entire length of roller contacts the table.

A piece of paper inserted between the roller and the

table should not fit.

10. When roller is level, adjust both rollers to desired

Height–of–Cut with pins. Tighten nuts securing roller

brackets and replace hairpin cotters to the Height of

cut pins.

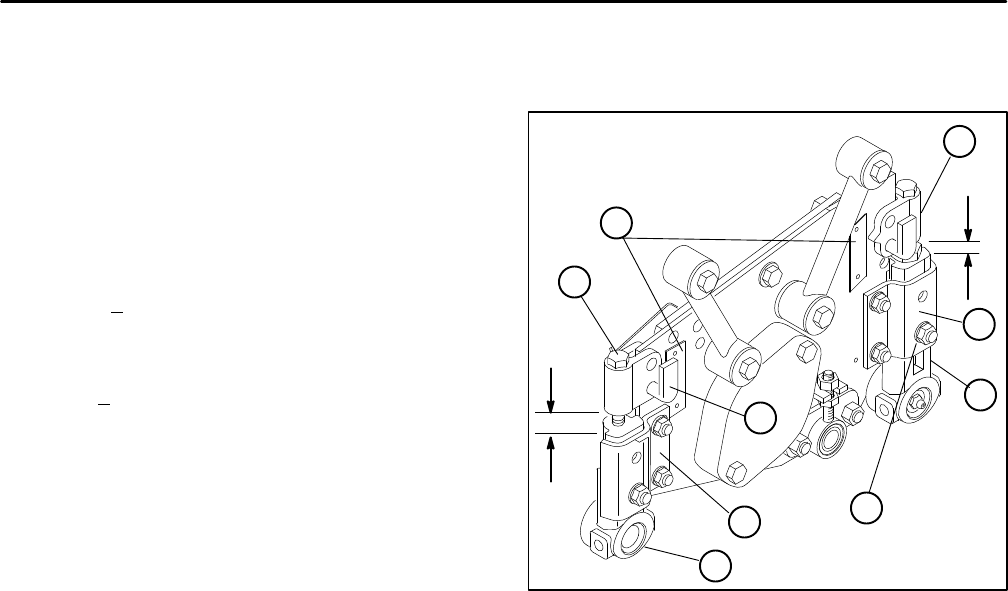

1. Nut

2. Rear roller bracket

3. Front roller bracket

4. Angle bracket

5. Support capscrew

6. Height–of–Cut support

7. Height–of–Cut pins

8. Height–of Cut plate

Figure 6

1”

5/8”

3

4

7

5

2

4

6

1

8