Reelmaster 3100−D Hydraulic System (Rev. C)

Page 4 − 45

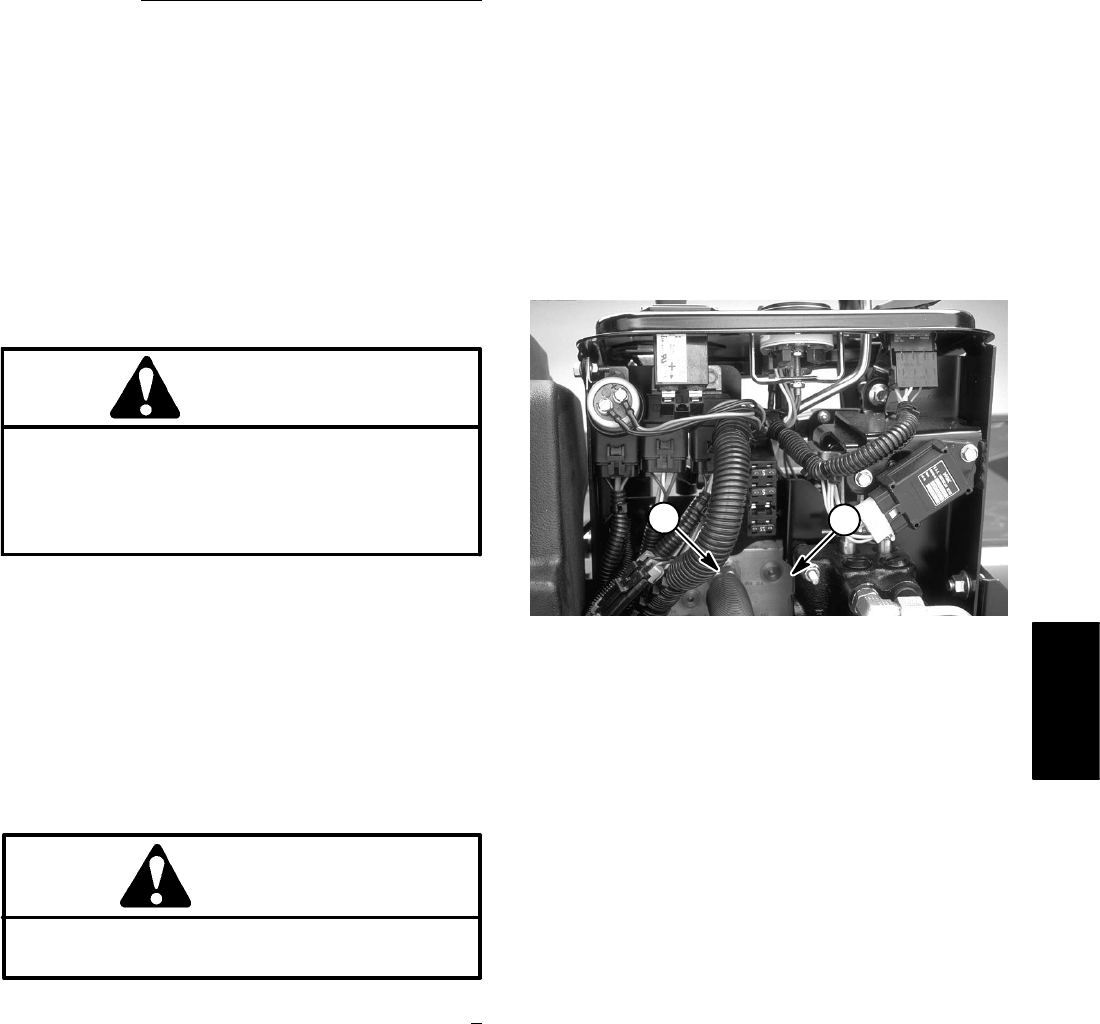

Procedure for Manifold Relief Valve (R1) Pressure

Test:

1. Make sure hydraulic oil is at normal operating tem-

perature by operating the machine for approximately 10

minutes.

2. Park machine on a level surface with the cutting units

lowered and off. Make sure engine is off and the parking

brake is engaged.

3. Read Precautions for Hydraulic Testing.

4. Make sure reel speed adjuster knob (FC1) is set to

the highest speed setting (fully open).

WARNING

Before disconnecting or performing any work

on the hydraulic system, all pressure in the

system must be relieved. See Relieving Hy-

draulic System Pressure in the General Infor-

mation section.

5. Disconnect hose connection from hydraulic fitting on

manifold port (M1).

6. Install tester in series with the hose and hydraulic fit-

ting. Make sure the flow control valve on tester is fully

open.

7. Make sure backlap knob on the hydraulic manifold is

in the mow position. Make sure reel speed knob is set

to maximum.

CAUTION

Keep away from reels during test to prevent per-

sonal injury from the rotating reel blades.

8. Start engine and move throttle to full speed (2650 +

50 RPM). Engage the cutting units.

9. Watch pressure gauge carefully while slowly closing

the flow control valve to fully closed.

10.System pressure should be from 2700 to 3300 PSI

as the relief valve lifts.

A. If specification is not met, shut off engine and ad-

just relief valve (see Adjusting Manifold Relief Valve).

Return to Step 6.

B. If this specification is met, go to Step 11.

11.Disengage cutting units. Shut off engine.

12.Disconnect tester from manifold and hose. Recon-

nect hydraulic hose to manifold fitting for port (M1).

1. Hydraulic manifold 2. Hydraulic fitting (M1)

Figure 25

1

2

Hydraulic

System