Rev. D

Reelmaster 3100−DHydraulic System (Rev. C)

Page 4 − 100

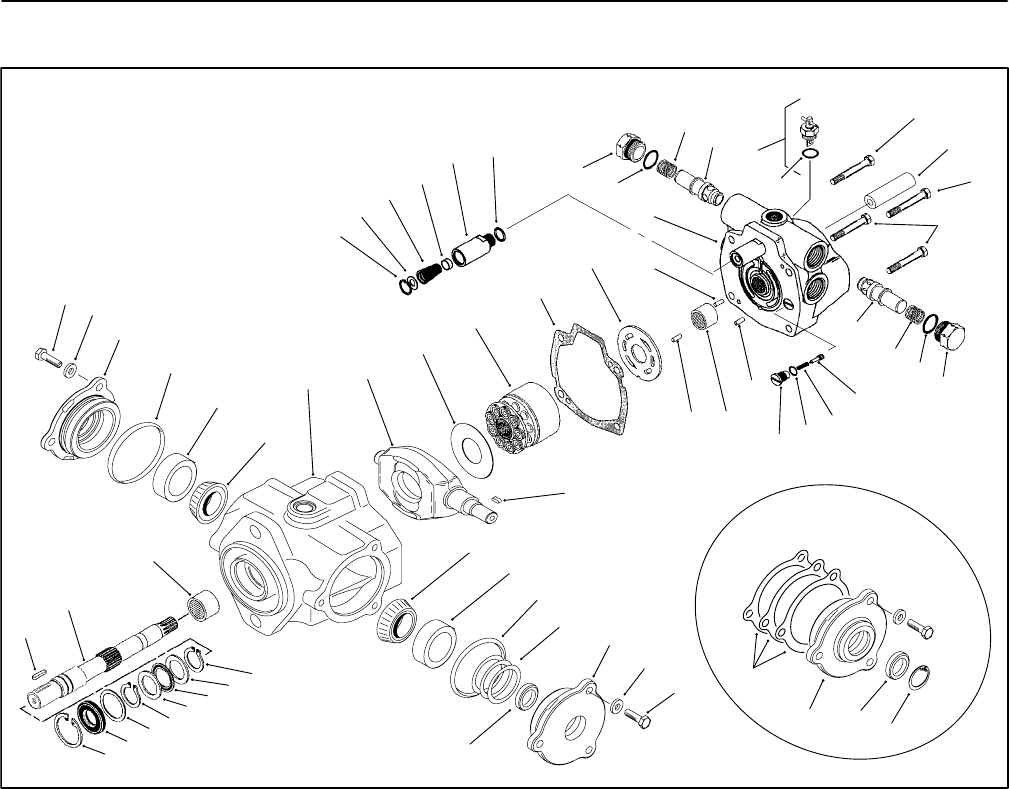

Piston Pump Service

1. Key

2. Drive shaft

3. Bearing

4. Cap screw (3 used per cover plate)

5. Cover plate

6. Seal

7. Shim kit

8. Bearing cone

9. Key

10. Cam plate

11. Rotating kit

12. Gasket

13. Valve plate

14. Bearing

15. Dowel pin

16. Back plate

17. O−ring

18. Plug

19. Spring

20. Seat

21. Dump valve

22. Cap screw

23. Cap screw

24. Roll pin

25. Cover plate

26. Bearing cup

27. Relief valve

28. Washer (3 used per cover plate)

29. Housing

30. Retaining ring

31. Bearing race

32. Thrust bearing

33. Washer

34. Shaft seal

35. Retaining ring

36. Bleed−off valve poppet

37. Bleed−off spring

38. O−ring

39. Cam plate insert

40. Shaft seal

41. O−ring

42. Coupler

43. Retaining ring

44. Washer

45. Charge relief spring

46. Charge relief poppet

47. Charge relief housing

48. O−ring

49. Cartridge

50. Shim (Model 70160−LAA−01)

51. Cover plate (70160−LAA−01)

52. Shaft seal (70160−LAA−01)

53. Retaining ring (70160−LAA−01)

Figure 66

31

32

33

34

35

1

2

3

18

19

27

21

22

23

20

17

18

19

31

30

30

38

4

4

40

25

7

5

6

6

8

8

29

16

17

24

11

12

13

14

15

15

39

10

9

22

42

28

26

26

43

46

47

44

45

48

49

28

53

70160−LAA−01

41

37

36

50

51 52

EATON MODEL

NOTE: For repair of the piston pump, see the Eaton

Medium Duty Piston Pump Repair Information Model

70160 Variable Displacement Piston Pump at the end of

this chapter.

NOTE: Reelmaster 3100−D machines with serial num-

bers below 90775 were equipped with an Eaton model

70160−LAA−01 piston pump. This pump included some

differences in the trunnion shaft design (Items 50 − 53

in Figure 66).

IMPORTANT: If a piston pump failure occurred, re-

fer to Traction Circuit (Closed Loop) Component

Failure in the General Information section for infor-

mation regarding the importance of removing con-

tamination from the traction circuit.