Reelmaster 3100−D Hydraulic System (Rev. C)

Page 4 − 35

Procedure for Charge Relief Valve Pressure

Test:

1. Make sure hydraulic oil is at normal operating tem-

perature by operating the machine for approximately 10

minutes.

2. Park machine on a level surface with the cutting units

lowered and off. Make sure engine is off and the parking

brake is engaged.

3. Read Precautions for Hydraulic Testing.

WARNING

Before disconnecting or performing any work

on the hydraulic system, all pressure in the

system must be relieved. See Relieving Hy-

draulic System Pressure in the General Infor-

mation section.

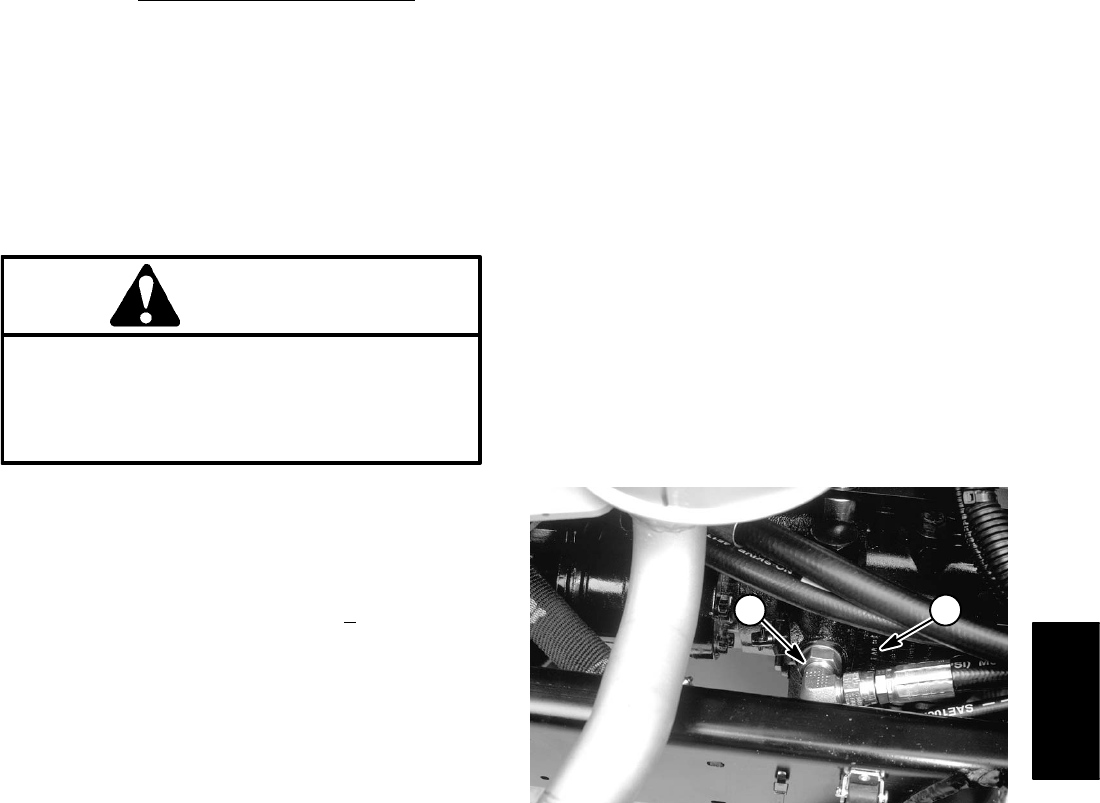

4. Disconnect hose to the rear 90

o

hydraulic fitting on

the piston pump coming from the hydraulic manifold port

(CHG). Connect T−connector and gauge to the fitting

and hose connection.

5. Operate engine at full speed (2650 +

50 RPM).

6. Make sure that traction pedal is in neutral and the

parking brake is engaged.

7. Pressure gauge should read from 100 to 150 PSI.

8. If charge relief pressure specification is not met, con-

sider the following:

A. The piston pump charge relief valve is faulty. Re-

pair or replace the piston pump charge relief valve

(see Piston Pump Service in the Service and Repairs

section).

B. Gear pump (P2) is faulty (steering and lift circuits

are also affected).

9. A dynamic charge pressure test can be performed as

follows:

A. With T−connector and pressure gauge still con-

nected, sit in the operator seat and press the traction

pedal to forward.

B. While machine is moving, monitor the charge

pressure reading on the pressure guage.

C. The charge pressure should drop no more than

15% from initial test reading (Step 7 above). A pres-

sure drop of more than 15% indicates a traction cir-

cuit leak (e.g. a worn or damaged piston pump

and/or wheel motor).

10.Shut off engine.

11.Disconnect gauge and T−connection from the 90

o

hydraulic fitting and hose connection. Reconnect hose

to the hydrostat.

1. Rear 90

o

hydraulic fitting 2. Piston pump

Figure 19

1

2

Hydraulic

System