Reelmaster 3100--D

DPA Cutting Units (Rev G)

Page 8 -- 32

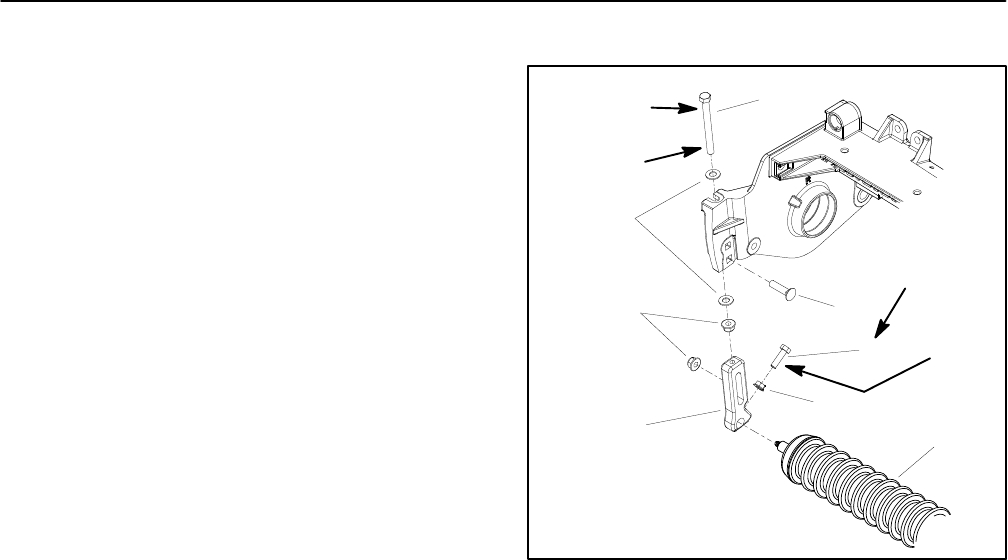

Front Roller

Removal (Fig. 30)

1. Position machine on a clean and level surface, lower

cutting units, stop engine, engage parking brake and re-

move key from the ignition switch.

2. Remove the cutting unit from the machine and place

on a level working surface. Use cutting unit kickstand

(see Special Tools) to raise front roller from work sur-

face.

3. Loosen flange nut and cap screw securing the front

roller shaft to each front height--of--cut (roller) bracket.

4. On one of the height--of--cut (roller) brackets:

A. Remove flange lock nut and carriage screw that

secure bracket to the cutting unit side plate.

B. Remove the height--of--cut (roller) bracket from

the cutting unit.

5. Slide the front roller assembly from the remaining

height--of--cut (roller) bracket on the cutting unit.

6. If necessary, remove the second height--of--cut (roll-

er) bracket from the cutting unit.

Installation (Fig. 30)

1. Place cutting unit on a level working surface and use

cutting unit kickstand (see Special Tools) to support cut-

ting unit.

2. Inspect condition of cap screws (item 1) in both

height--of--cut (roller) brackets. Replace cap screw(s) if

necessary:

A. Place two (2) flat washers on cap screw and

thread flange lock nut onto cap screw to a position

0.750” (19 mm) from screw head.

B. Apply antiseize lubricant to cap screw threads

that will extend into height--of--cut (roller) bracket.

C. Thread cap screw into bracket.

Note: When assembling height--of--cut (roller) brack-

ets toside plate,make surethat capscrew headand one

washer are above adjustment flange on side plate and

second washer and flange lock nut are below flange.

3. If both front height--of--cut (roller) brackets were re-

moved from cutting unit side plate, position one of the

brackets to side plate. Secure bracket to side plate with

carriage screw and flange lock nut.

1. Cap screw

2. Flat washer

3. Flange lock nut

4. HOC (roller) bracket

5. Carriage screw

6. Cap screw

7. Flange nut

8. Front roller assembly

Figure 30

1

2

3

4

5

6

7

8

15 to 19 ft--lb

(20to26N--m)

Antiseize

Lubricant

Loctite #242

Loctite #242

4. Slide front roller shaft into bracket attached to the

cutting unit. Slide second height--of--cut (roller) bracket

onto the otherend of roller shaft. Secure secondbracket

to cutting unit side plate with carriage screw and flange

nut.

5. Apply Loctite #242 (or equivalent) to exposed

threads of cap screw (item 1) between flange of side

plate and position of flange lock nut (item 3) on cap

screw. Tighten flange lock nut on cap screw and then

loosen nut1/4 to 1/2 turn.Cap screw should rotatefreely

with little (if any) endplay after lock nut installation.

6. Apply Loctite #242 (or equivalent) to threads of two

(2) cap screws (item 6). Center front roller to the cutting

reel and secure in place with two (2) cap screws. Torque

cap screws from 15 to 19 ft--lb (20 to 26 N--m). Secure

cap screws with flange nuts.

7. Lubricate front roller.

8. Adjust cutting unit (see Cutting Unit Operator’s

Manual).