Reelmaster 3100−DPage 5 − 28Electrical Systems (Rev. C)

Electrical System Quick Check

Battery Test (Open Circuit Test)

Use a multimeter to measure the voltage between the

battery terminals.

Set multimeter to the DC volts setting. The battery

should be at a temperature of 60 to 100

o

F (16 to 38

o

C).

The ignition key should be off and all accessories turned

off. Connect the positive (+) meter lead to the positive

battery post and the negative (−) meter lead the the neg-

ative battery post.

NOTE: This test provides a relative condition of the bat-

tery. Load testing of the battery will provide additional

and more accurate information.

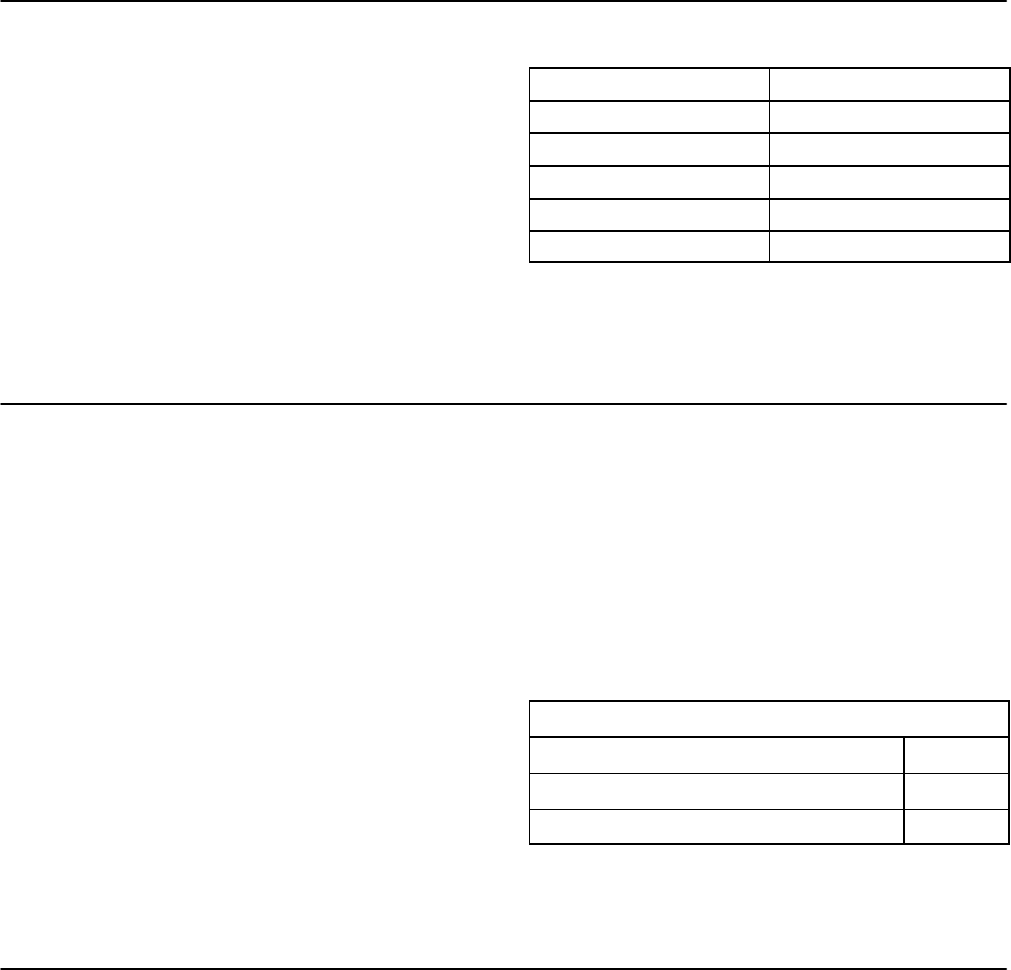

Voltage Measured

Battery Charge Level

12.68 V (or higher) Fully charged (100%)

12.45 V 75% charged

12.24 V 50% charged

12.06 V 25% charged

11.89 V 0% charged

Charging System Test

This is a simple test used to determine if a charging sys-

tem is functioning. It will tell you if the charging system

has an output, but not its capacity.

Tool required: Digital multimeter set to DC volts.

Test instructions: Connect the positive (+) multimeter

lead to the positive battery post and the negative (−)

multimeter lead to the negative battery post. Keep the

test leads connected to the battery posts and record the

battery voltage.

NOTE: Upon starting the engine, the battery voltage

will drop and then should increase once the engine is

running.

NOTE: Depending upon the condition of the battery

charge and battery temperature, the charging system

voltage will increase at different rates as the battery

charges.

Start the engine and run at high idle (2650 RPM). Allow

the battery to charge for at least 3 minutes. Record the

battery voltage.

After running the engine for at least 3 minutes, battery

voltage should be at least 0.50 volt higher than initial bat-

tery voltage.

Example of a charging system that is functioning:

At least 0.50 volt over initial battery voltage.

Initial Battery Voltage = 12.30 v

Battery Voltage after 3 Minute Charge = 12.85 v

Difference = +0.55 v

Glow Plug System Test

This is a fast, simple test that can help to determine the

integrity and operation of the Reelmaster 3100−D glow

plug system. The test should be run anytime hard start-

ing (cold engine) is encountered on a diesel engine

equipped with a glow plug system.

Tool(s) required: Digital multimeter and/or inductive

Ammeter (AC/DC Current Transducer).

Test instructions: Properly connect the ammeter to the

digital multimeter (refer to manufacturers’ instructions).

Set the multimeter to the correct scale. With the ignition

switch in the OFF position, place the ammeter pickup

around the main glow plug power supply wire and read

the meter prior to activating the glow plug system. Adjust

the meter to read zero (if applicable). Activate the glow

plug system (see Traction Unit Operator’s Manual) and

record the multimeter results.

The Reelmaster 3100−D glow plug system should have

a reading of approximately 27 Amps.