Reelmaster 3100−D

Page 3 − 12

Kubota Diesel Engine

Check Air Filter, Dust Cup, & Burp Valve

The air cleaner body, air filter, dust cup, and burp valve

should be check daily prior to operation.

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake, and remove key

from the ignition switch.

2. Check air cleaner body for damage that could cause

possible air leaks. Make sure dust cup seals completely

to the air cleaner body.

3. Check burp valve and dust cup for damage.

4. Make sure air hoses connecting the air cleaner to the

engine and radiator are secured tightly and free of pos-

sible air leaks.

Service Air Filter, Dust Cup, & Burp Valve

The air cleaner filter should be serviced ever 50 hours,

and more frequently in extreme dusty conditions.

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake, and remove key

from the ignition switch.

2. Release latches securing air cleaner cover to air

cleaner body. Separate cover from body. Clean inside of

air cleaner cover.

3. Gently slide filter out of air cleaner body to reduce the

amount of dust dislodged. Avoid knocking filter against

air cleaner body.

4. Inspect filter and discard if damaged. Do not wash or

reuse a damaged filter.

IMPORTANT: Do not over service the air filter ele-

ment; damage may result.

Washing Method

A. Prepare a solution of filter cleaner and water.

Soak filter element about 15 minutes. Refer to direc-

tions on filter cleaner carton for complete informa-

tion.

B. After soaking filter for 15 minutes, rinse it with

clear water. Maximum water pressure must not ex-

ceed 40 psi to prevent damage to the filter element.

Rinse filter from clean side to dirty side.

C. Dry filter element using warm, flowing air (160

o

F

maximum), or allow element to air−dry. Do not use a

light bulb to dry the filter element because damage

could result.

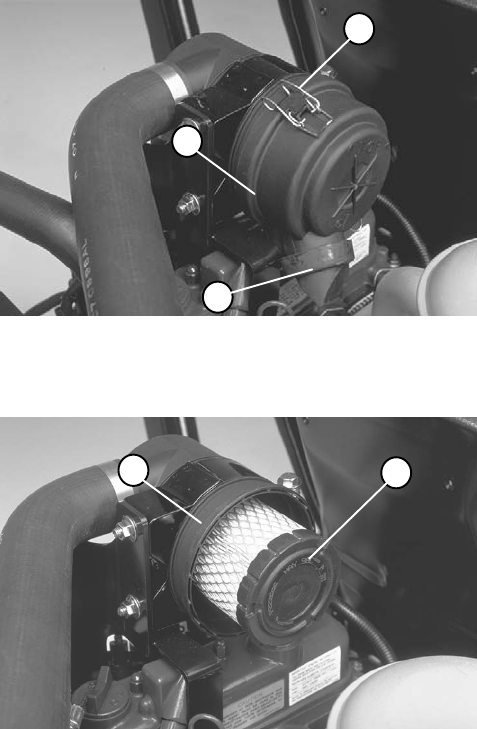

Figure 18

1. Latch

2. Dust cup

3. Burp valve

2

1

3

Figure 19

1. Filter element 2. Body

2

1

Compressed Air Method

A. Blow compressed air from inside to the outside of

dry filter element. Do not exceed 100 psi to prevent

damage to the element.

B. Keep air hose nozzle at least 2 inches (5 cm) from

the filter. Move nozzle up and down while rotating the

filter element. Inspect for holes and tears by looking

through the filter toward a bright light.

5. Inspect new filter for shipping damage. Check seal-

ing end of filter. Do not install a damaged filter.

6. Insert new filter properly into air cleaner body. Make

sure filter is sealed properly by applying pressure to out-

er rim of filter when installing. Do not press on flexible

center of filter.

7. Reinstall cover and secure latches. Make sure cover

is positioned with TOP side up.