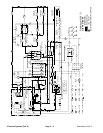

Reelmaster 3100−D Hydraulic System (Rev. C)

Page 4 − 123

Disassembly

1. Remove oil from the steering cylinder into a drain pan

by slowly pumping the cylinder shaft. Plug both ports

and clean the outside of the cylinder.

IMPORTANT: Prevent damage when clamping the

hydraulic cylinder into a vise; clamp on the clevis

only.

2. Mount clevis end of steering cylinder in a vice. Re-

move retaining ring.

3. Extract shaft, head, and piston by carefully twisting

and pulling on the shaft.

IMPORTANT: Do not clamp vise jaws against the

shaft surface. Protect shaft surface before mount-

ing in a vice.

4. Mount shaft securely in a vise by clamping on the cle-

vis of the shaft. Remove lock nut and piston from the

shaft. Slide head off the shaft.

5. Remove Uni−ring and O−ring from the piston.

6. Remove back−up ring, O−rings, and rod seal from

the head.

Reassembly

1. Make sure all parts are clean before reassembly.

2. Coat new O−rings, Uni−ring, rod seal, and back−up

ring with with clean hydraulic oil.

A. Install Uni−ring and O−ring to the piston.

B. Install O−rings, back−up ring, and rod seal to the

head.

IMPORTANT: Do not clamp vise jaws against the

shaft surface. Protect shaft surface before mount-

ing in a vice.

3. Mount shaft securely in a vise by clamping on the cle-

vis of the shaft.

A. Coat shaft with a light coat of clean hydraulic oil.

B. Slide head onto the onto the shaft. Install piston

and lock nut onto the shaft. Torque nut from 24 to 30

ft−lb (33 to 41 N−m).

C. Remove shaft from the vise.

IMPORTANT: Prevent damage when clamping the

hydraulic cylinder into a vise; clamp on the clevis

only.

4. Mount clevis of the barrel in a vice.

5. Coat all internal parts with a light coat of clean hy-

draulic oil. Slide piston, shaft, and head assembly into

the barrel being careful not to damage the seals.

6. Secure head in the barrel with the retaining ring.

Hydraulic

System