Reelmaster 3100−DHydraulic System (Rev. C)

Page 4 − 96

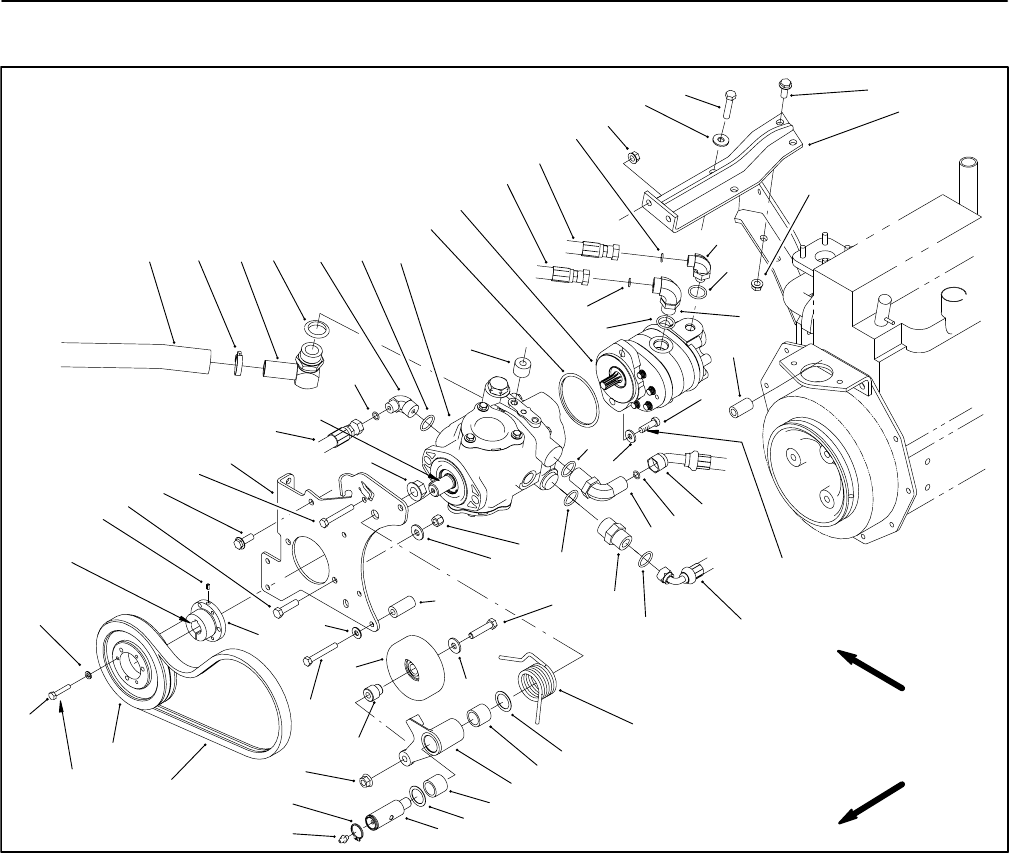

Piston Pump

1. Piston pump

2. Straight hydraulic fitting

3. Cap screw

4. Lock nut

5. 90

o

hydraulic fitting

6. 90

o

hydraulic fitting

7. 90

o

hydraulic fitting

8. 90

o

hydraulic fitting

9. 90

o

hydraulic fitting

10. Washer

11. Hydraulic hose

12. Suction hose

13. Flange nut

14. Idler pivot pin

15. Grease fitting

16. Flange nut

17. Retaining ring

18. Cap screw

19. Thrust washer

20. Idler pulley

21. Spacer

22. Torsion spring

23. Idler arm

24. Hose clamp

25. Flange nut

26. Cap screw

27. Flange head screw

28. Pump support

29. Spacer

30. Cap screw

31. Flat washer

32. Spacer

33. Pump mount plate

34. Pump mount spacer

35. Pulley

36. Cap screw

37. Lock washer

38. Taper lock bushing

39. V−belt

40. O−ring

41. O−ring

42. O−ring

43. O−ring

44. O−ring

45. O−ring

46. O−ring

47. O−ring

48. Hydraulic hose

49. Hydraulic hose

50. Hydraulic hose

51. Hydraulic hose

52. Bushing

53. Gear pump

54. O−ring

55. Flat washer

56. Socket head screw

57. Set screw

Figure 62

31

32

33

34

35

36

37

38

39

1

2

3

4

5

6

7

8

9

10

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

11

12

13

1415

25

10

10

27

48

47

45

44

49

50

43

45

44

42

51

40

40

41

41

52

52

53

54

55

56

30

57

19

FRONT

RIGHT

Antiseize

Lubricant

Antiseize

Lubricant

27 to 31 ft−lb

(37 to 42 N−m)

90 to 120 in−lb

(10.2 to 13.6 N−m)

IMPORTANT: If a piston pump failure occurred, re-

fer to Traction Circuit (Closed Loop) Component

Failure in the General Information section for infor-

mation regarding the importance of removing con-

tamination from the traction circuit.