Reelmaster 3100--D

DPA Cutting Units (Rev G)

Page 8 -- 34

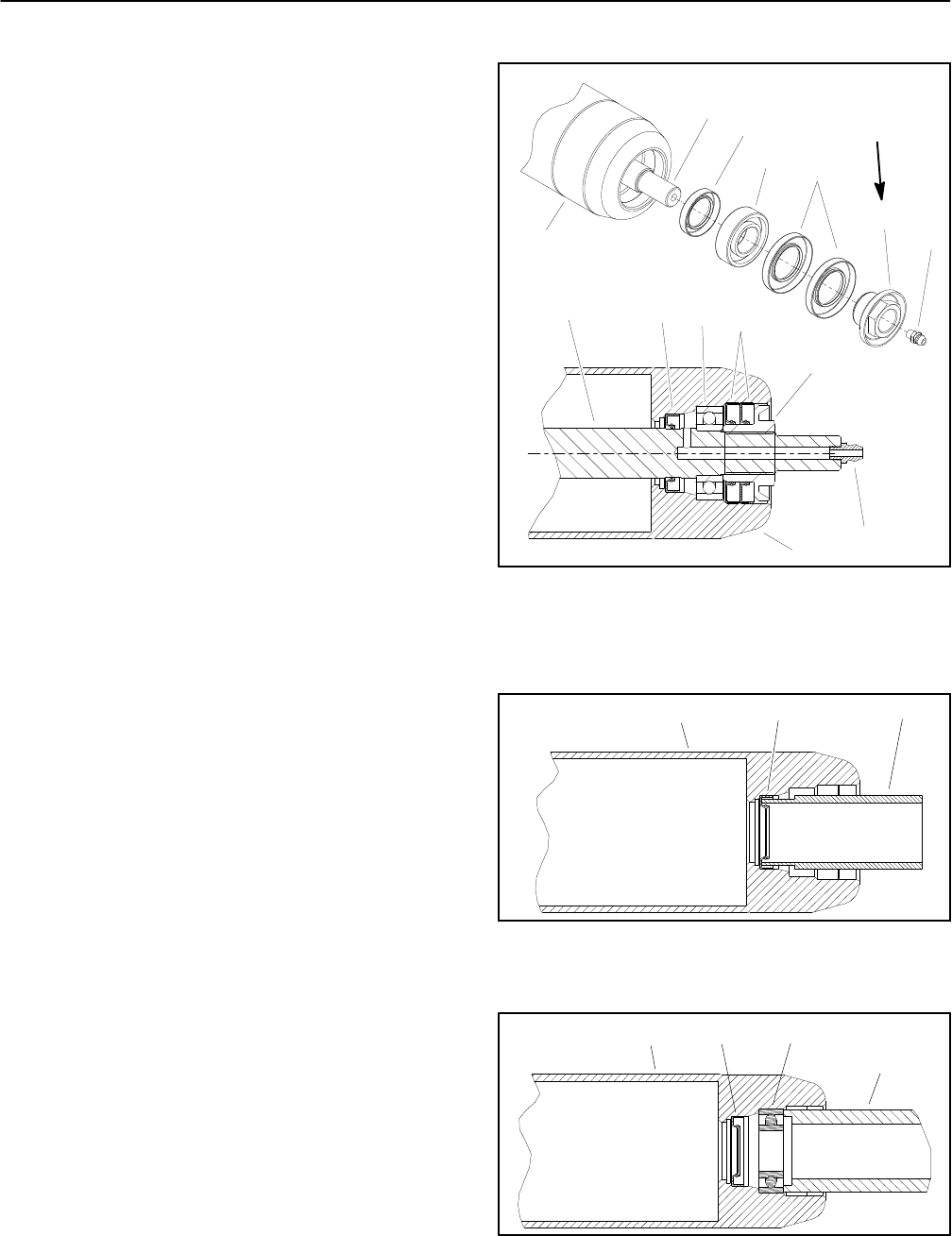

Roller Service

Disassembly (Fig. 32)

1. Remove bearing lock nut from each end of roller

shaft.

2. Loosely secure roller assembly in bench vise and

lightly tap one end of roller shaft until outer seals and

bearing are removed from opposite end of roller tube.

Remove second set ofouter seals and bearing from roll-

er tube by tapping on opposite end of shaft. Remove

shaft from roller tube.

3. Carefully remove inner seal from both ends of roller

tube taking care to not damage tube surfaces.

4. Discard removed seals and bearings.

5. Clean roller shaft and all surfaces on the inside of the

roller tube. Inspect components for wear or damage.

Also, carefully inspect seating s urface and threads of

bearing lock nuts. Replace all damaged components.

Assembly (Fig. 32)

1. Install inner seals into roller tube making sure that

seal lip (and garter spring) faces end of tube. Use inner

seal tool(see Special Tools)and soft facehammer toful-

ly seat seals against roller shoulder (Fig. 33). Apply a

small amountof greasearound the lipof both inner seals

after installation.

IMPORTANT: During assembly process, frequently

check that bearings rotate freely and do not bind. If

any binding is detected, consider component re-

moval and reinstallation.

2. Install new bearing and outer seals into one end of

roller tube:

A. Position a new bearing into one end of roller tube.

Use bearing/outer seal tool (see Special Tools) with

a soft face hammer to fully seatbearing against roller

shoulder (Fig. 34). After bearing installation, make

sure that it rotates freely with no binding.

B. Apply a small amount of grease around the lip of

both outer seals.

C. Install first outer seal into roller tube making sure

that seal lip (and garter spring) faces end of tube.

Use bearing/outer seal tool (see Special Tools) and

soft face hammer to lightly seat seal against roller

shoulder (Fig. 35). Make sure that bearing s till freely

rotates after seal installation.

D. Using the same process, install second outer

seal makingsure tonot crush theinstalled outerseal.

Again, make sure that bearing still freely rotates.

1. Roller tube

2. Roller shaft

3. Inner seal

4. Bearing

5. Outer seal

6. Bearing lock nut

7. Grease fitting

Figure 32

6

3

5

4

2

1

7

50 to 60 ft--lb

(68to81N--m)

6

3

5

4

2

1

7

1. Roller tube

2. Inner seal

3. Inner seal tool

Figure 33

321

1. Roller tube

2. Inner seal

3. Bearing

4. Washer

5. Bearing/outer seal tool

Figure 34

321

4