Reelmaster 3100−D Hydraulic System (Rev. C)

Page 4 − 69

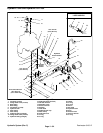

Rear Wheel Removal

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake, and remove key

from the ignition switch.

WARNING

Before jacking up the machine, review and follow

Jacking Instructions in Chapter 1 − Safety.

2. Jack up rear of machine enough to allow the removal

of the rear wheel.

3. Remove rear tire and rim assembly from machine.

4. Remove rear wheel motor with wheel hub attached

from the rear fork using Figure 43 as guide.

5. Secure wheel hub in a vise. Loosen but do not re-

move lock nut that secures wheel hub to wheel motor.

IMPORTANT: DO NOT hit wheel hub, wheel hub

puller or wheel motor with a hammer during wheel

hub removal or installation. Hammering may cause

damage to the wheel motor.

6. Using hub puller (see Special Tools), loosen wheel

hub from wheel motor.

7. Remove wheel hub and motor from vise. Remove

lock nut and hub from motor shaft. Locate and retrieve

woodruff key.

8. If hydraulic fittings are to be removed from wheel mo-

tor, mark fitting orientation to allow correct assembly.

Rear Wheel Installation

1. If hydraulic fittings were removed, install fittings to

reel motor using marks made during the removal pro-

cess to properly orientate fittings.

2. Thoroughly clean wheel motor shaft and wheel hub

taper.

3. Clamp wheel hub in a vise. Install woodruff key into

the wheel motor shaft. Slide motor shaft into hub and se-

cure with lock nut. Torque lock nut from 250 to 350 ft−lb

(339 to 474 N−m). Remove wheel motor and hub from

vise.

4. Install wheel motor to the rear fork using Figure 43 as

guide.

5. Install tire and rim assembly to machine.

6. Lower the machine to the ground.

7. Torque rear wheel lug nuts from 45 to 65 ft−lb (61 to

88 N−m).

8. Make sure hydraulic tank is full. Add correct oil if nec-

essary (see Operator’s Manual).

Hydraulic

System