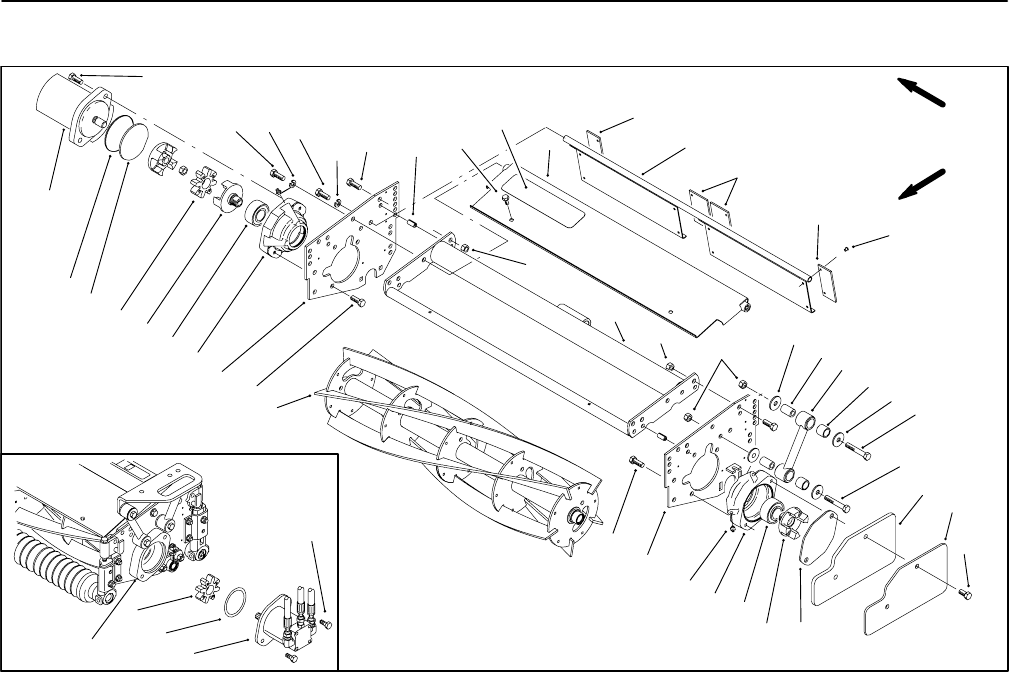

Reelmaster 3100−DPage 7 − 16Cutting Units

Reel Motor Removal and Installation

1. Reel

2. Cap screw

3. Not used

4. Cap screw

5. Lock washer

6. Side plate (RH)

7. Roll pin

8. Lock nut

9. Hex nut

10. Waring decal

11. Front grass guard

12. Frame assembly

13. Rear grass guard

14. Flange nut

15. Side plate (LH)

16. Washer

17. Spacer

18. Link

19. Bushing

20. Cap screw

21. Cap screw

22. Cap screw

23. Not used

24. Reel coupler (LH)

25. Grease fitting

26. Hex flange head screw

27. Bearing housing

28. Bearing

29. Reel coupler (RH)

30. Spider coupler

31. Not used

32. Not used

33. Cover gasket

34. O−ring

35. Shipping plug

36. Weight (3.5 lbs)

37. Weight (2.0 lbs)

38. Rubber side cover

39. Rubber center cover

40. Rivet

41. Hydraulic motor

Figure 22

33

34

35

36

37

1

2

4

5

6

7

8

9

10

16

17

18

19

20

21

22

24

25

26

27

28

29

30

11

12

13

14

15

2

5

2

38

38

39

40

8

16

26

27

28

41

FRONT

RIGHT

30

34

2

41

27

Removal

1. Remove two capscrews holding the hydraulic motor

to the bearing housing.

2. Remove hydraulic motor and spider coupling from

the bearing housing. Position hydraulic motor away

from the cutting unit prior to removing or working on the

cutting unit.

Inspection

1. Inspect spider coupling for wear. Replace worn cou-

pling with new one.

2. Check coupling inside bearing housing. If coupling is

loose remove and check for worn threads. Replace cou-

pling if threads are worn. Reinstall coupling (see Reel

Removal and Bearing Replacement).

Installation

Note: The cutting unit can be installed with the hy-

draulic motor on either side. If installing on the opposite

side, remove cap screws, weights, and cover gasket; re-

install them on the other bearing housing.

1. Dip spider coupling in No. 2 general purpose lithium

base grease. Reinstall spider coupling into the bearing

housing.

2. Install O−ring on the front plate of the motor. Mount

hydraulic motor to the bearing housing. Secure motor

with the two capscrews.

3. Grease bearing housing sufficiently to fill housing

with grease (see Greasing Bearings, Bushings, and Piv-

ot Points).