Reelmaster 3100−D Hydraulic System (Rev. C)

Page 4 − 27

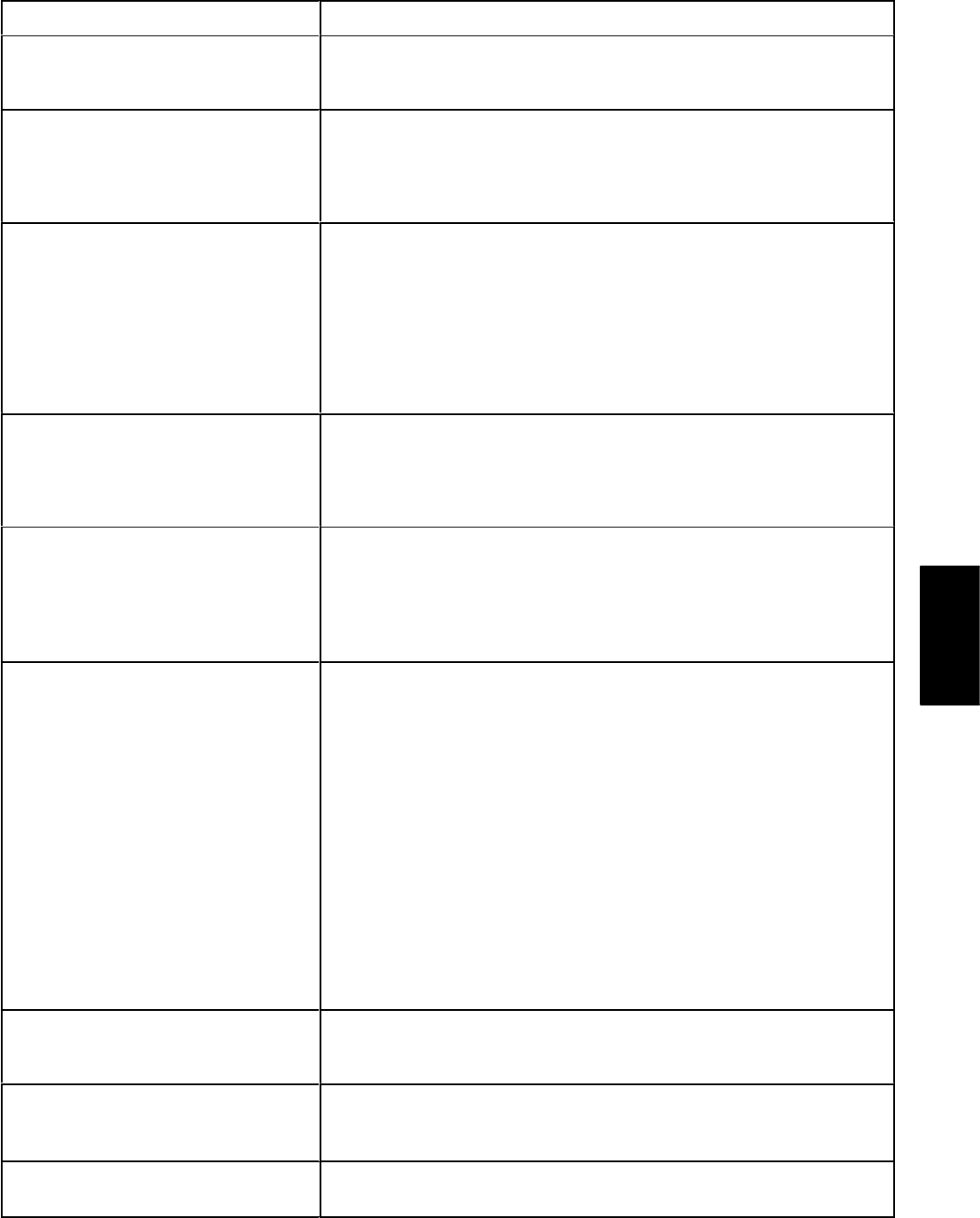

Problem Possible Cause

Wheel motor will not hold load in

neutral.

Make up fluid from charge pump is not available.

Hydrostat ball check valves are damaged.

Reel motor drive pump is noisy (ca-

vitation).

Reservoir oil level is low.

Suction line is restricted.

Suction line has an air leak.

Reels will not turn. Solenoid valve S1 is stuck open.

An electrical problem exists (See Chapter 5−Electrical System).

Relief valve R1 is stuck open.

LC1 logic valve is stuck open.

Gear pump P1 is damaged.

Reel speed is erratic. Reel to bedknife adjustment is too tight.

Orifice for LC1 is obstructed.

Reel bearing(s) are damaged.

Reel(s) turn too slowly. Reel section of pump (P1) is inefficient (see Testing).

Reel motor has internal leakage or malfunctioning cross−over relief

valve (see Testing).

Reel bearing(s) are damaged.

Cutting units will not lift or lift slowly. Engine speed is too low.

Charge (gear) pump is damaged.

Lift cylinder linkage is binding or broken.

Lift cylinder bushings are binding.

Reservoir oil level is low.

Charge pump pressure or flow is insufficient.

Implement relief valve (1000 PSI) is stuck open.

Lift cylinders leak internally.

Steering control valve is defective.

Cutting units raise, but will not stay

up.

Lift cylinders leak internally.

Check valve within the lift valve leaks.

Steering Problems. See Ross Troubleshooting Guide in the Hydraguide

TM

Hydrostatic

Steering System HGF Series Service Procedure at the end of this

chapter.

Turning steering wheel turns ma-

chine in the opposite direction.

Hoses to the steering cylinder are reversed.

Hydraulic

System