Reelmaster 3100−DPage 7 − 22Cutting Units

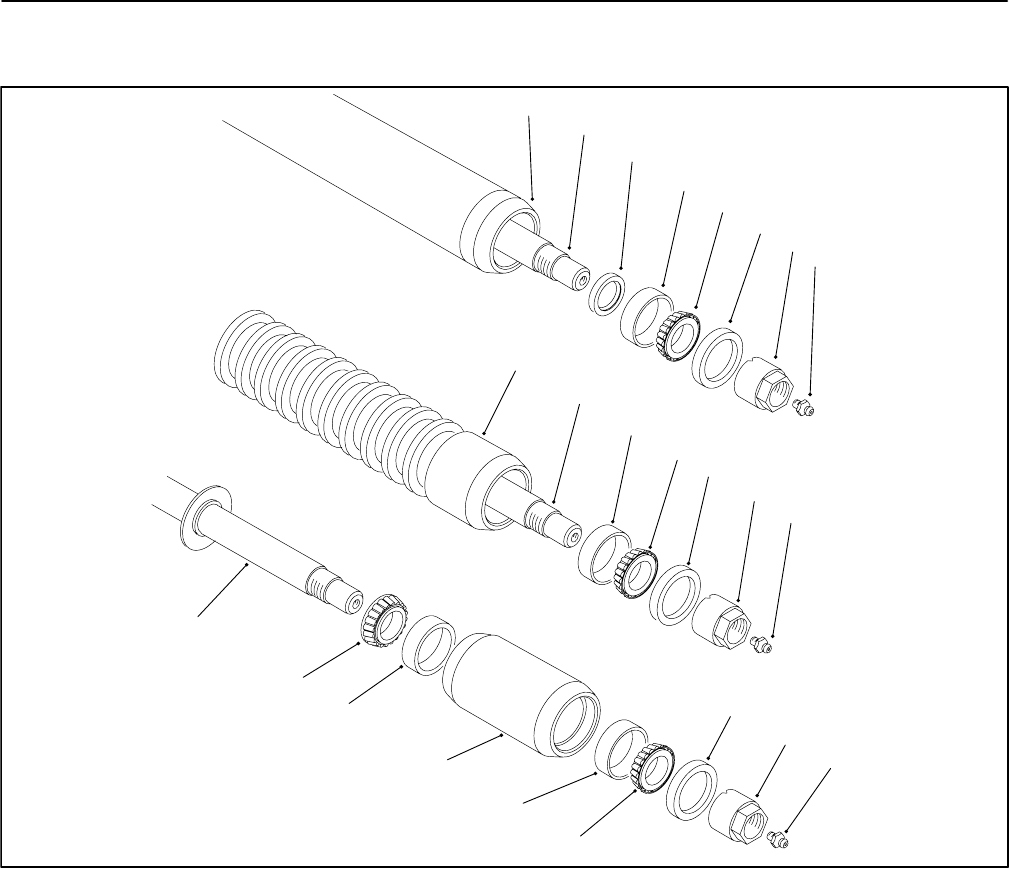

Roller Bearing and Seal Replacement

1. Full roller

2. Roller shaft

3. Grease seal

4. Bearing cup

5. Bearing cone (outer)

6. Outer seal

7. Adjustment nut

8. Grease fitting

9. Wiehle roller

10. Sectional roller shaft

11. Bearing cone (inner)

12. Sectional roller

Figure 28

1

2

3

4

5

10

11

12

7

8

9

4

4

5

6

2

6

7

8

4

5

6

7

8

Remove Seals and Bearings

1. Clean inside of roller around both adjusting nuts and

roller shaft ends. Both areas should be free of dirt and

debris.

2. Remove adjusting nut from one end of the roller

shaft. On the sectional roller, remove both adjusting nuts

from each end of the roller.

NOTE: When disassembling a full roller, pour the oil

from inside the roller into a suitable container.

3. Keep roller level and slide the shaft with the remain-

ing adjusting nut out of the roller. On the sectional roller,

slide both sectional rollers of the shaft.

4. Secure roller in a vise.

5. Remove outer seals.

6. Remove both bearing cones. On the sectional roller,

remove all four bearing cones.

Note: An electric arc welder can be used to shrink the

bearing cup to simplify its removal. Only a small arc in

one location on the cup is required.

7. Remove both bearing cups from the roller. Remove

both inner seals installed on the full roller. On the sec-

tional roller, remove all four bearing cups.

8. Discard seals and bearings.