Rev. E

Reelmaster 3100--DHydraulic System (Rev. C)

Page 4 -- 74

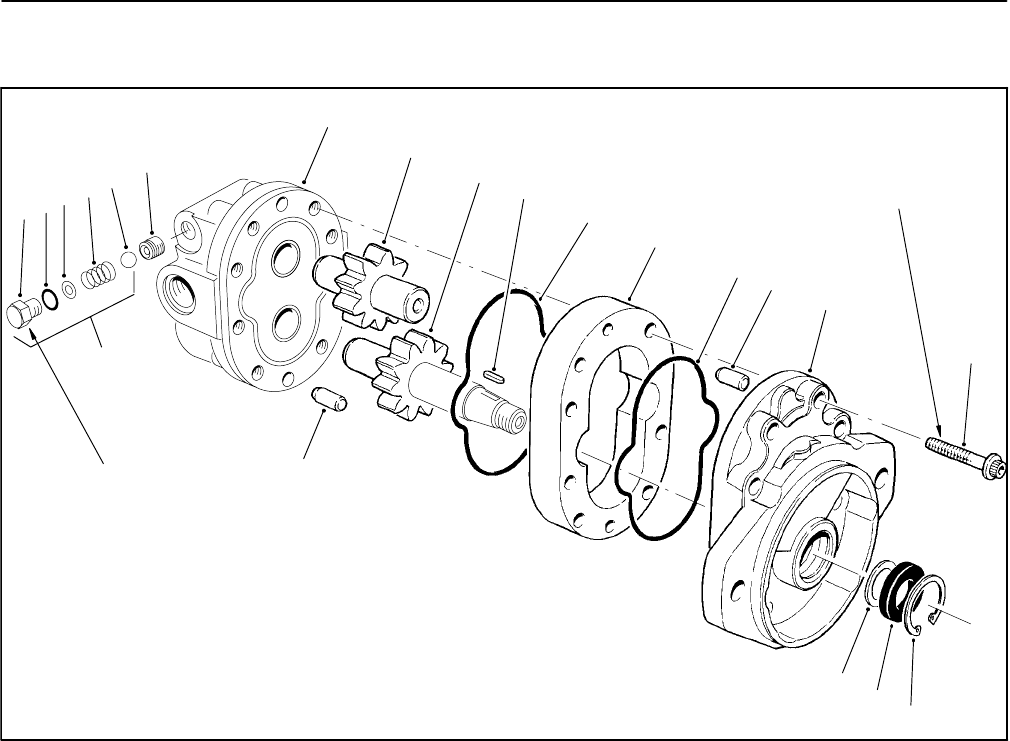

Reel Motor Service (Eaton)

1. Plug

2. O--ring

3. Shim

4. Spring

5. Ball

6. Relief valve seal

7. Backplate

8. Idler gear assembly

9. Drive gear assembly

10. Key

11. O--ring

12. Body

13. Alignment pin

14. Frontplate

15. Cap screw

16. Retaining ring

17. Oil seal

18. Backup washer

19. Relief valve assembly (items 1 thru 6)

Figure 46

1

2

3

4

5

6

7

8

9

10

16

17

18

19

11

12

13

14

15

11

13

25 to 28 ft--lb

(34to38N--m)

10 to 12 ft--lb

(13.6 to 16.3 N--m)

Disassembly (Fig. 46)

1. Make sure key is removed from the drive gear shaft.

2. Matchmark frontplate, body,and backplate toassure

proper reassembly.

3. Secure the motor in a vise with the drive shaft up.

4. Remove all cap screws used to assemble motor.

5. Remove the motor from the vise. Remove the front-

plate from the body. A wooden block or soft face ham-

mer might be used to gently tap the motor when freeing

the frontplate.

6. Remove alignment pin from the body. Remove drive

gear and idler gear from the body.

7. Remove body from the backplate. Remove O--rings

from the body and backplate.

8. Remove alignment pin from the backplate.

9. Remove retaining ring, oil seal, and backup washer

from the frontplate.

IMPORTANT: Do not remove the relief valve as-

sembly unless testing shows it to be faulty. The re-

lief valve assembly must be replaced as a complete

unit. Both relief valve seals are sealed in place with

thread sealant; do not remove them.

10.Remove plug, O--ring, shim, spring, andball from the

backplate.