Reelmaster 3100−D Hydraulic System (Rev. C)

Page 4 − 39

Procedure for Wheel Motor Efficiency

Test:

1. Make sure hydraulic oil is at normal operating tem-

perature by operating the machine for approximately 10

minutes. Make sure the hydraulic tank is full.

2. Park machine on a level surface with the cutting units

lowered and off. Make sure engine is off and the parking

brake is engaged.

3. Read Precautions for Hydraulic Testing.

4. Make sure that traction pedal is adjusted to the neu-

tral position (see Adjust Traction Drive for Neutral in the

Adjustments Section).

5. Attach a heavy chain to the rear of the machine frame

and an immovable object to prevent the machine from

moving during testing.

The rear wheel will be off the ground during front

wheel motor testing. Make sure machine is sup-

ported so it will not move and accidentally fall to

prevent injuring anyone under machine.

WARNING

6. Block up the rear wheel off the ground to allow flow

through the traction circuit.

7. Chock front wheel being tested to prevent rotation of

the wheel. Make sure parking brake is on.

WARNING

Before disconnecting or performing any work

on the hydraulic system, all pressure in the

system must be relieved. See Relieving Hy-

draulic System Pressure in the General Infor-

mation section.

8. Disconnect hydraulic lines from front wheel motor

that is not being tested. Cap disconnected hydraulic

lines and plug ports in motor to prevent contamination.

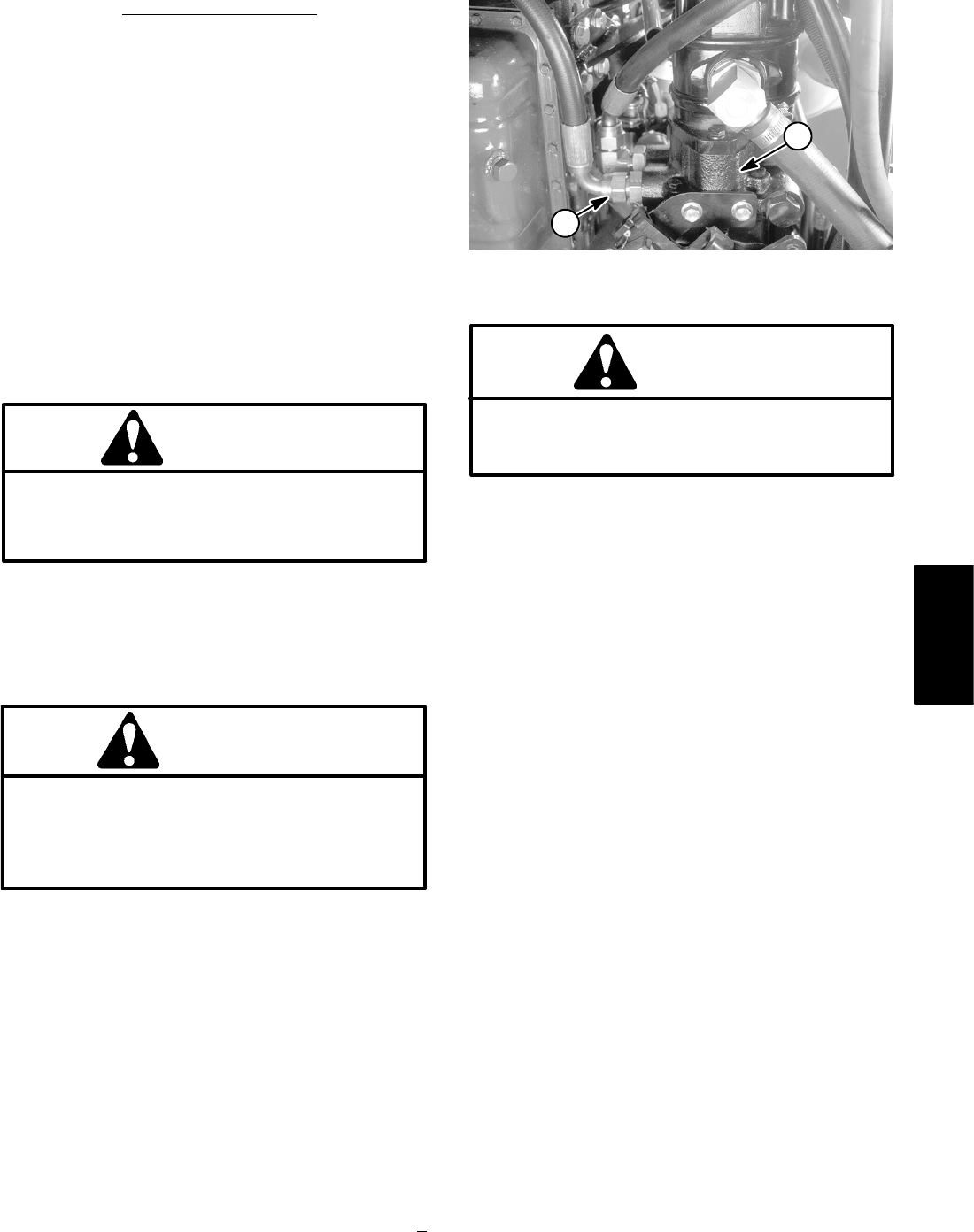

9. Disconnect hose from the lower hydraulic fitting on

the bottom of the hydrostat (Fig. 22).

NOTE: An alternate testing location would be at the hy-

draulic hose connection to the hydraulic tube under the

left floor plate.

10.Install flow tester in series with the pump and the dis-

connected hose. Make sure the tester flow control valve

is fully open.

11.Start engine and move throttle to full speed (2650 +

50 RPM).

1. Lower hydraulic fitting 2. Piston pump

Figure 22

1

2

CAUTION

Use extreme caution when performing test. The

front tire on the ground will be trying to move the

machine forward.

12.Slowly push traction pedal in forward direction until

1000 PSI is displayed on the pressure gauge.

13.Motor internal leakage will be shown on flow meter

in GPM. Flow should be less than 1.5 GPM for the

tested wheel motor.

14.If specifications are not met, the tested wheel motor

needs to be repaired or replaced as necessary.

15.If remaining front wheel motor requires testing, com-

plete steps 5 to 14 for the remaining motor.

16.If rear wheel motor requires testing:

A. Both front wheel motors should have hydraulic

lines connected. Block up both front wheels off the

ground. Release parking brake so front wheels can

turn.

B. Attach a heavy chain to the rear of the machine

frame and an immovable object to prevent the ma-

chine from moving during testing.

C. Position rear wheel on the ground and chock rear

wheel to prevent it from turning.

D. Complete steps 9 to 13.

E. If specifications are not met, check the relief valve

in the rear wheel motor for damage. If relief valve is

not damaged, wheel motor needs to be repaired or

replaced.

17.Disconnect tester from hydraulic fitting and hose.

Reconnect hose to pump connection.

Hydraulic

System