Reelmaster 3100−D

Page 1 − 4

Safety

Jacking Instructions

CAUTION

When changing attachments, tires, or performing

other service, use correct blocks, hoists, and

jacks. Make sure machine is parked on a solid lev-

el floor such as a concrete floor. Prior to raising

machine, remove any attachments that may inter-

fere with the safe and proper raising of the ma-

chine. Always chock or block wheels. Used jack

stands or solid wood blocks to support the raised

machine. If the machine is not properly sup-

ported by blocks or jack stands, the machine may

move or fall, which may result in personal injury.

Use the following positions when jacking up the ma-

chine:

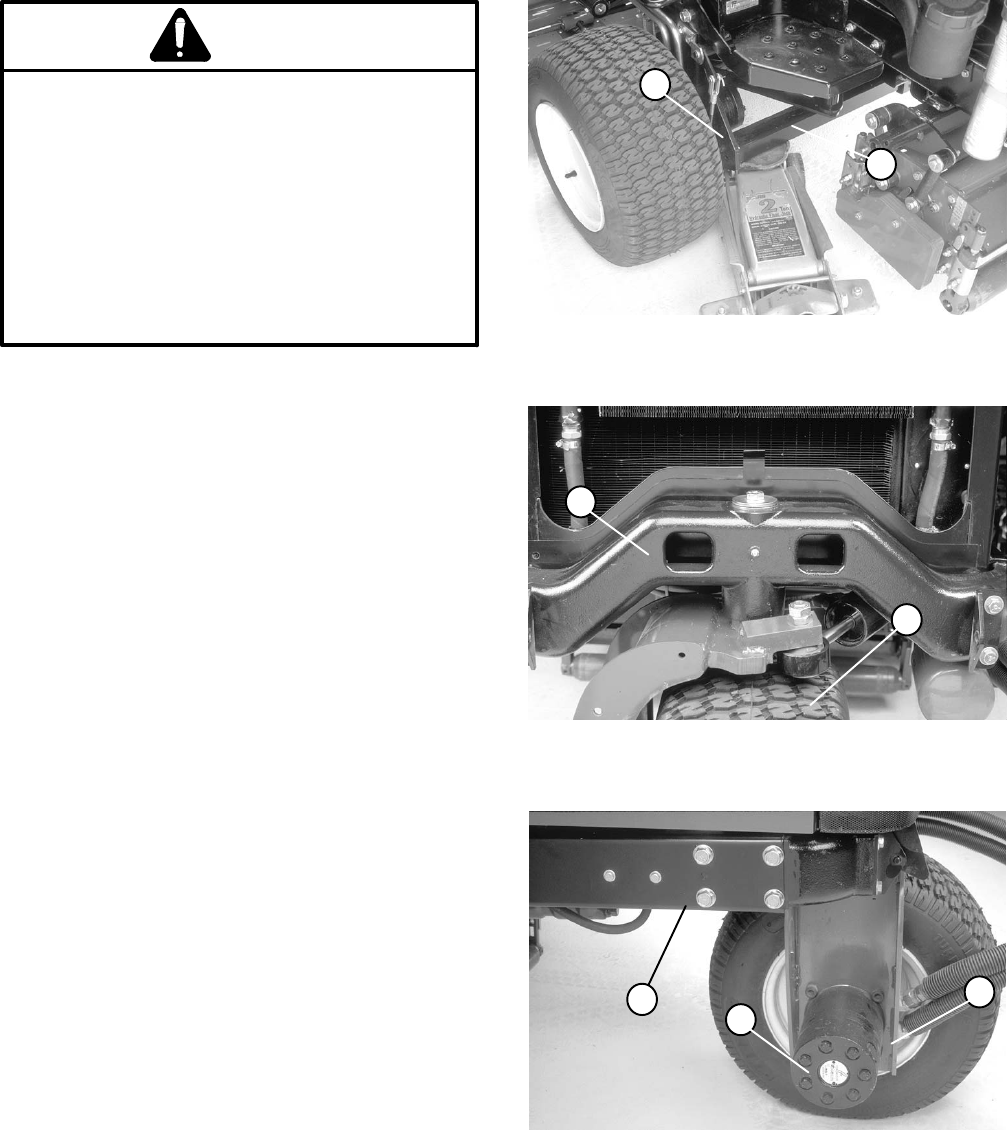

Jacking the Front End

1. If the front wheel motor is to be removed, position

jack securely under the square tube of the lower frame

as closely to the side plate as possible (Fig. 1).

2. If the front tire is to be removed, position the jack se-

curely under the front wheel motor.

3. Use jack stands or hardwood blocks under the

square tube or wheel motors to support the machine

(Fig. 1).

Jacking the Rear End

1. The preferred method of lifting the rear end of the

machine for removing the rear fork or the rear wheel mo-

tor:

A. Secure a chain fall or hoist to the rear casting (Fig

2).

B. Chock both front tires. Lift rear tire off the ground.

C. Use jack stands or hardwood blocks under the

frame to support the machine (Fig. 3).

2. If the rear of the machine can not be lifted from above

(Fig. 3),

IMPORTANT: Make sure jack is as close to the rear

fork as possible when jacking the rear wheel.

A. Place jack securely under the rear wheel motor.

B. Chock both front tires. Jack rear tire off the

ground.

C. Use jack stands or blocks under the frame to se-

cure the machine.

1. Square tube 2. Side plate

Figure 1

2

1

1. Rear tire 2. Rear casting

Figure 2

2

1

1. Frame

2. Rear wheel motor

3. Rear fork

Figure 3

2

3

1