Reelmaster 3100−DPage 5 − 32Electrical Systems (Rev. C)

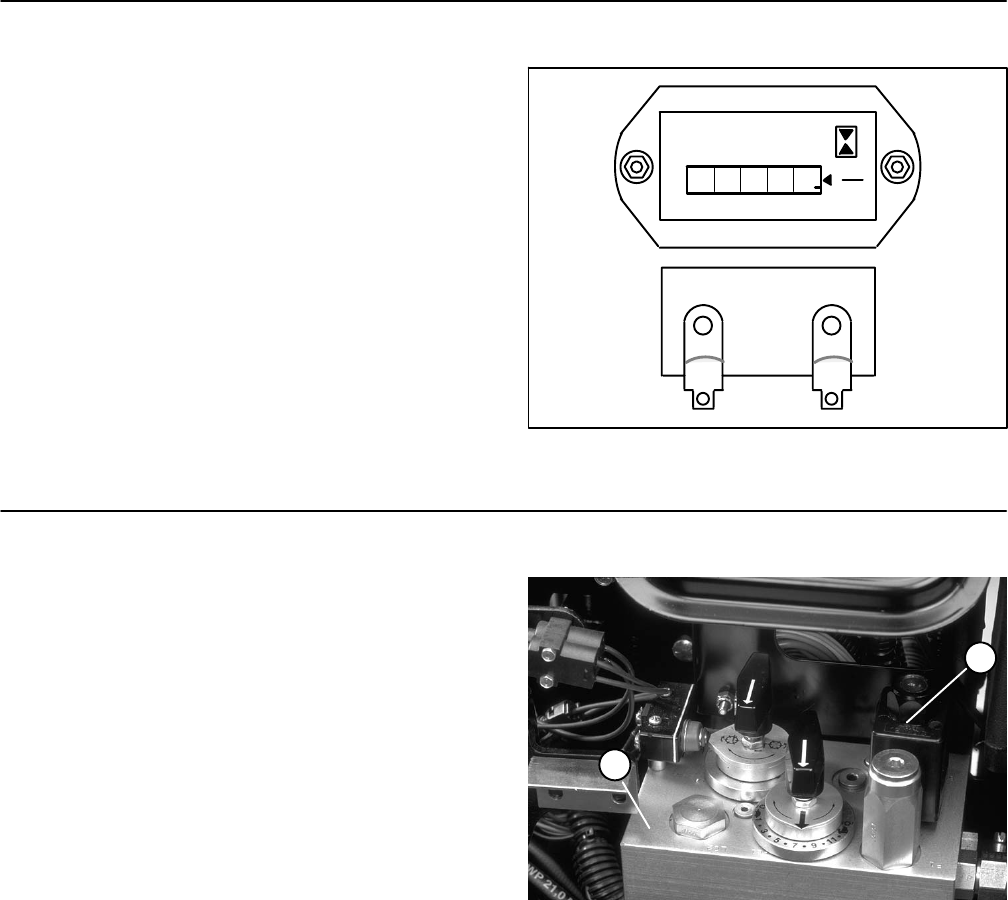

Hour Meter

1. Connect the positive (+) terminal of a 12 VDC source

to the positive terminal of the hour meter.

2. Connect the negative (−) terminal of the voltage

source to the other terminal of the hour meter.

3. The hour meter should move a 1/10 of an hour in six

minutes.

4. Disconnect the voltage source from the hour meter.

Figure 9

QUARTZ

Hobbs

HOURS

1

0000

1

10

+

BACK

Reel Drive Solenoid

Note: Prior to taking small resistance readings with a

digital multimeter, short the test leads together. The me-

ter will display a small resistance value (usually 0.5

ohms or less). This resistance is due to the internal re-

sistance of the meter and test leads. Subtract this value

from from the measured value of the component you are

testing.

1. Make sure engine is off. Disconnect solenoid valve

electrical connector.

2. Apply 12VDC source directly to the solenoid. Listen

for solenoid to switch on.

3. Remove 12VDC source from the solenoid. Listen for

solenoid to switch off.

4. Measure resistance between the two connector ter-

minals. The resistance should be about 7.2 ohms.

5. Install new solenoid if necessary.

A. Make sure o−ring is installed at each end of coil.

Apply ”Loctite 242” or equivalent to threads on end of

valve stem before installing nut.

B. Tighten nut to a torque of 15 in−lb (17.3 kg−cm).

Over−tightening may damage the solenoid or cause

the valve to malfunction.

6. Reconnect electrical connector to the solenoid.

Figure 10

1. Hydraulic manifold 2. Solenoid

2

1