Rev. C Reelmaster 3100−DPage 6 − 6Wheels, Brakes, and Miscellaneous

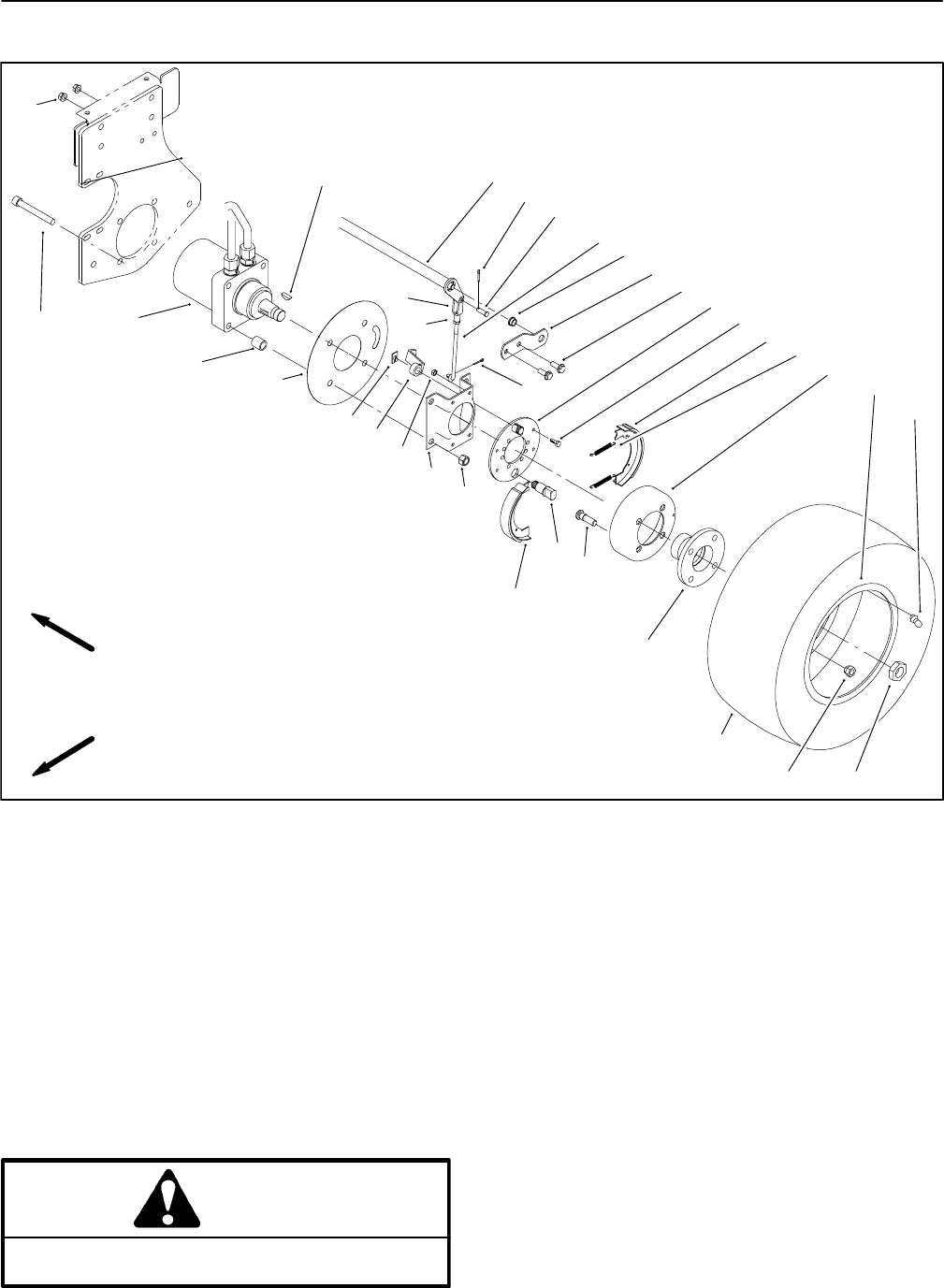

Front Wheel and Brake

1. Lug nut

2. Drive stud

3. Wheel rim

4. Tire

5. Wheel hub

6. Lock nut

7. Hydraulic motor

8. Brake drum

9. Woodruff key

10. Cotter pin

11. Adjustment rod

12. Brake lever

13. Lock nut

14. Cap screw

15. Brake bracket

16. Return spring

17. Brake shoe

18. Backing plate

19. Cam shaft

20. Retainer Clip

21. Lock nut

22. Cap screw

23. Spacer

24. Wheel shield

25. Cotter pin

26. Clevis pin

27. Clevis

28. Jam nut

29. Flange bushing

30. Brake pivot bracket

31. Brake pivot shaft

32. Hex flange head screw

33. Hex flange nut

Figure 7

FRONT

RIGHT

10

28

31

30

32

29

3

41

8

2

6

4

1

14

13

24

12

27

26

25

11

15

21

5

18

19

20

16

17

17

7

23

22

33

9

Removal (Fig. 7)

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake, and remove key

from the ignition switch.

WARNING

Before jacking up the machine, review and follow

Jacking Instructions in Chapter 1 − Safety.

2. Jack up front wheel and use wood blocks to keep the

rear tire off the floor.

3. Remove lug nuts from drive studs. Pull wheel from

drive studs and wheel hub.

NOTE: The installation torque of the locknut is from 250

to 400 ft−lb (339 to 542 N−m). Use impact wrench to re-

move lock nut from the hydraulic motor shaft.

4. Loosen, but do not remove, lock nut from the hydrau-

lic motor shaft. Release parking brake.