3-8 PXA250 and PXA210 Applications Processor Design Guide

LCD Display Controller

3.5 Additional Design Considerations

3.5.1 Contrast Voltage

Many displays, both active and passive, include a pin for adjusting the display contrast voltage.

This is a variable analog voltage that is supplied to the panel via an voltage source on the system

board. The contrast voltage is adjusted via a variable resistor on the circuit board.

The required voltage range and current capabilities vary between panel manufacturers. Consult the

datasheet for your panel to determine the variable voltage circuit design. Ensure that the contrast

voltage is stable, otherwise visual artifacts might result. Possible contrast-voltage circuits are often

suggested by the panel manufacturers.

3.5.2 Backlight Inverter

One potential source of noise for the LCD panel can be the backlight inverter. Since this is a high

voltage device with frequent voltage inversions, it has the potential to inject spurious noise onto the

LCD panel lines. To minimize noise:

• Use a shielded backlight inverter

• Physically locate the inverter as far away from the LCD data lines and system board as

possible, usually located with the LCD panel

If power consumption is an issue, chose a backlight inverter that can be disabled through software.

This lets you save power by automatically disabling the backlight if no activity occurs within a

preset period of time

3.5.3 Signal Routing and Buffering

Signal transmission rates between the LCD controller and the LCD panel are moderate, which

helps to simplify the design of the LCD system. The minimum Pixel Clock Divider (PCD) value

results in a pixel clock rate of one half of the LCLK (this is not the L_LCLK of the LCD

controller.) The maximum LCLK for the PXA250 applications processor is 166 MHz, resulting in

a maximum pixel clock rate of 83 MHz. Thus, use of 100 MHz design considerations are sufficient

to ensure LCD panel signal integrity.

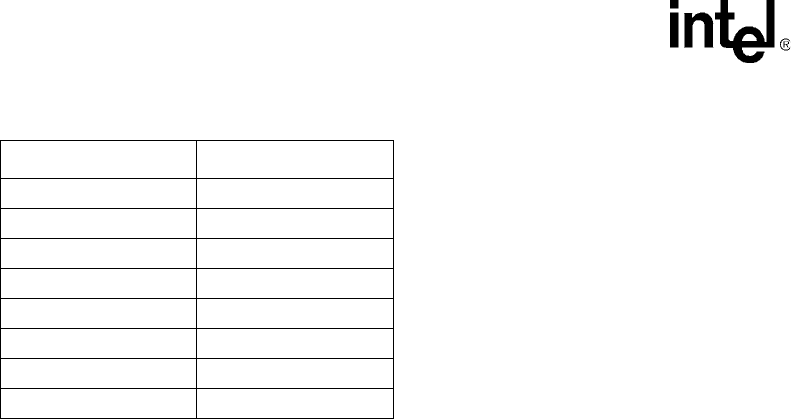

L_DD12 A3

L_DD13 A2

L_DD14 C3

L_DD15 B3

L_FCLK E8

L_LCLK D8

L_PCLK B8

Bias A8

Table 3-4. PXA250 LCD Controller Ball Positions (Sheet 2 of 2)

Pin Name Ball Position