Reelmaster 5010 Series Hydraulic System (Rev. C)Page 4 -- 35

CAUTION

Before openinghydraulic system, operateall hy-

draulic controls to relieve system pressure and

avoid injury from pressurized hydraulic oil. See

Relieving HydraulicSystemPressure inthe Gen-

eral Information section of this chapter.

4. Raise and prop operator seat to allow access to hy-

draulic pump.

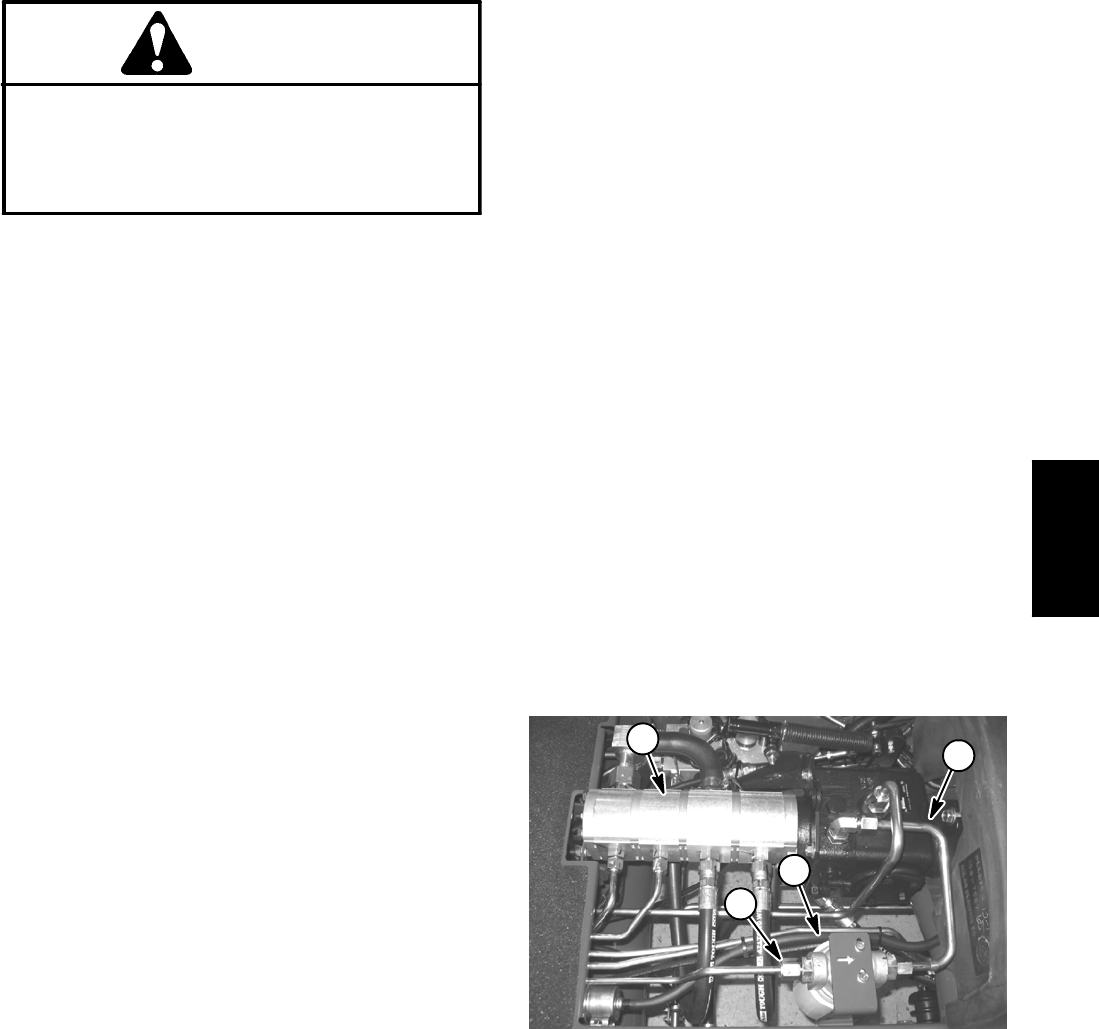

5. Thoroughly clean the ends of the hydraulic tubes

connected to the oil filter and traction pump inlets (Fig.

32). Disconnect hydraulic tubes from oil filter inlet and

traction pumpinlet. Remove two(2) flangehead screws

that secure oil filter adapter to frame. Remove oil filter

assembly and hydraulic tube from machine.

IMPORTANT: Make sure that the oil flow indicator

arrow on the flow meter is showing that the oil will

flow from the hydraulic tube, through the tester and

into the traction pump.

6. Install tester with pressure gauges and flow meter in

place of the removed oil filter assembly and hydraulic

tube. Connect tester inlet hose to the hydraulic tube.

Connect the tester outlet hose to the traction pump fit-

ting.Make surethe flowcontrol valveontester isful-

ly open.

7. Make sure that the traction pedal is in neutral, the

steering wheelis stationary andthe parking brake isen-

gaged.

8. Startengine and runat idle speed.Check for any hy-

draulic leakage from test connections and correct be-

fore proceeding with test.

9. Move throttle to full speed (3200 RPM).Usea

tachometer to verify that engine speed is correct.

IMPORTANT: The gear pump is a positive displace-

ment type. If pump flow is completely restricted or

stopped, damage to the pump, tester or other com-

ponents could occur.

10.While watching pressure gauges, slowly close the

tester flow control valve until 800 PSI (55 bar) is ob-

tained on gauge.

FLOW TESTER READING TO BE: A pump in good

condition should have a flow of approximately 4.7

GPM (17.8 LPM) at 800 PSI (55 bar).

11.Open the tester flow control valve, stop engine and

record test results.

12.If flow is less than 4GPM(15.1LPM)or a pressure

of 800 PSI (55 bar) cannot be obtained, consider that a

pump problem exists. Check for restriction in pump in-

take line. If intake is not restricted, remove gear pump

and repair or replace pump as necessary (see Gear

Pump in the Service and Repairs section of this chap-

ter).

NOTE: Iftheflowfromgearpump(P3)islow,theopera-

tion ofboth the chargecircuit and thesteering circuit will

be affected.

13.After testing is completed, make sure that engine is

stopped, then relieve hydraulic system pressure (See

Relieving Hydraulic System Pressure in the General In-

formation sectionof thischapter). Connectremoved hy-

draulic tube to oil filter and traction pump fittings.

14.Lower and secure operator seat.

1. Hydraulic tube

2. Oil filter / filter adapter

3. Hydraulic tube

4. Gear Pump (P3)

Figure 32

3

2

4

1

Hydraulic

System