Reelmaster 5010 SeriesHydraulic System (Rev. C) Page 4 -- 22

Troubleshooting

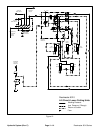

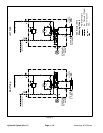

The cause of an improperly functioning hydraulic sys-

tem is best diagnosed with the use of proper testing

equipment and a thorough understanding of the com-

plete hydraulic system.

A hydraulic system with an excessive increase in heat

ornoise hasapotential forfailure.Shouldeither ofthese

conditions be noticed, immediately stop the machine,

turn off the engine, locate the cause of the trouble and

correct it before allowing the machine to be used again.

Continued use of an improperly functioning hydraulic

system could lead to extensive hydraulic component

damage.

The charts that follow contain information to assist in

troubleshooting. There may possibly be more than one

cause for a machine malfunction.

Refer to the Testing section of this chapter for precau-

tions and specific hydraulic test procedures.

General Hydraulic System Problems

Problem Possible Cause

Hydraulic oil leaks from machine Fitting(s), hose(s) or tube(s) is (are) loose or damaged.

O--r ing(s) or seal(s) is (are) missing or damaged.

Foaming hydraulic fluid Oil level in hydraulic reservoir is low.

Hydraulic system has wrong kind of oil.

Pump suction line has an air leak.

Hydraulic system operates hot Traction system pressure is high due to excessive load or brake

dragging or binding.

Oil level in hydraulic reservoir is low.

Hydraulic oil is contaminated or too light.

Engine speed is too low.

Oil cooler is damaged or plugged. Air flow through oil cooler is ob-

structed.

Oil filter is plugged.

Charge pressure is low.

Piston (traction) pump bypass valve is open or faulty.

Piston (traction) pump check valve is not seating or is damaged.

Wheel motor(s) and/or piston (traction) pump are worn or damaged

(NOTE: If a traction circuit component has internal wear or dam-

age, it is possible that other traction components are also dam-

aged).