Rev. B

Reelmaster 5010 Series Page 5 -- 45 Electrical System

Fuel Pump

The Reelmaster fuel pump is attached to the inside of

the left side frame rail near the fuel tank (Fig. 65).

IMPORTANT: When testing fuel pump, make sure

that pump is not operated without fuel.

DANGER

Becausedieselfuelishighlyflammable,usecau-

tionwhen handlingit.Donotsmoke whiletesting

thefuelpump.Donot testfuelpumpwhileengine

is hot. Make sure that there is adequate ventila-

tion when testing. Always wipe up any spilled

fuel before starting the engine.

Fuel Pump Capacity Test

1. Park machine on a level surface, lower cutting units,

stop engine and engage parking brake. Remove key

from ignition switch. Raise operator seat and hood.

2. Disconnect harness electrical connector from the

engine fuel stop solenoid to prevent the engine from

starting (see Fuel Stop Solenoid in this section).

3. Disconnect fuel hose (pump discharge) from the

fuel/water separator inlet fitting (Fig. 66).

4. Make sure fuel hosesattached to the fuel pump, fuel

filter and fuel tank suction tube screen are free of ob-

structions.

5. Placedisconnected hoseinto alarge,graduated cyl-

inder sufficient enough to collect 1 quart (0.95 liter).

IMPORTANT: When testing the fuel pump, DO NOT

turn ignition switch to START.

Note: Machines that are equipped with a Biodiesel

Conversion Kit will have the same fuel pump as ma-

chines with serial numbers above 280000000.

6. Collect fuel in the graduated cylinder by turning igni-

tion switch to the RUN position. Allow pump to run for

time listed below, then return switch to OFF.

A. For machines with serial numbers below

280000000, the amount of fuel collected in thegrad-

uated cylinder should be approximately 11.8 fl oz

(350 ml) after thirty (30) seconds.

B. For machines with serial numbers above

280000000, the amount of fuel collected in thegrad-

uated cylindershould beapproximately 16fl oz(475

ml) after fifteen (15) seconds.

7. Replace fuel pump if necessary. Install fuel hose to

the fuel/water separator. Make sure to secure fuel hose

with hose clamp.

8. Connect harness electrical connector to the engine

fuel stop solenoid.

9. Bleed the fuel system.

10.Lower and secure operator seat and hood.

Fuel Pump Specifications

Fuel pump specifications for machines with serial num-

bers below 280000000 are as follows:

Pump Capacity

23.5 fl oz/min (700 ml/min)

Pressure 3.3 PSI (22.8 kPa)

Current Draw 0.9 amp

Fuel pump specifications for machines with serial num-

bers above 280000000 are as follows:

Pump Capacity

64 fl oz/min (1.9 liters/min)

Pressure 7 PSI (48.3 kPa)

Current Draw 2.0 amp

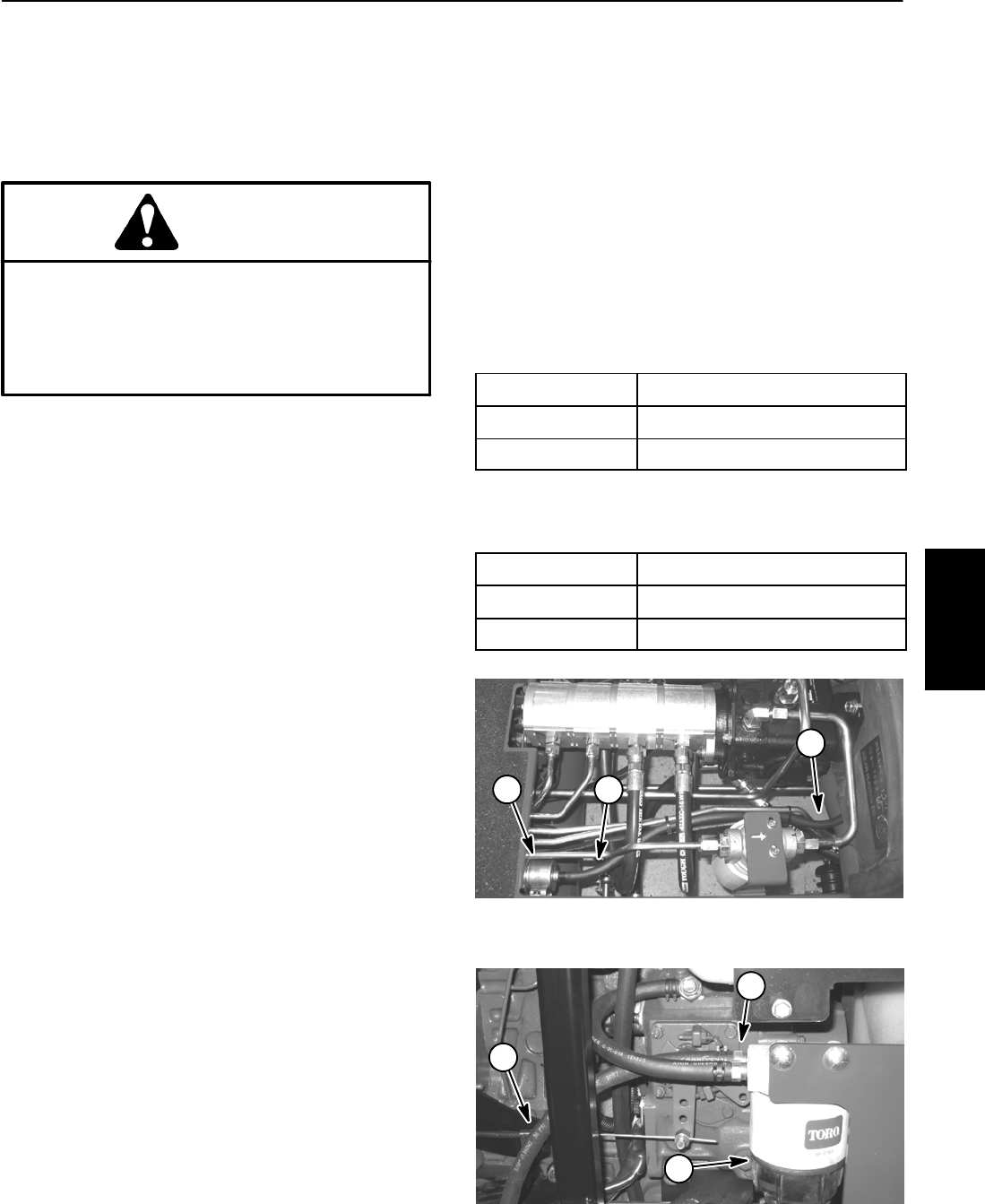

Figure 65

1. Fuel pump 2. Pump discharge hose

1

2

2

1. Fuel/water separator

2. Fuel hose (from pump)

3. Inlet fitting

Figure 66

1

2

3

Electrical

System