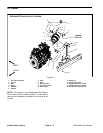

Reelmaster 5010 SeriesPage 3 -- 16Kubota Diesel Engine

9. Disconnect hydraulic transmission drive shaft from

engine (see Hydraulic T ransmission Drive Shaft Re-

moval in the Service and Repairs section of Chapter 4

-- Hy draulic System). Support drive shaft away from en-

gine.

10.Disconnect wireharness connectors from the follow-

ing engine components:

NOTE: Before disconnecting wire harness connectors,

label all electrical leads for assembly purposes.

A. Alternator connector and stud.

B. Oil pressure switch located near the engine oil fil-

ter.

C. Connector, fusible link connector and positive

battery cable from the starter motor.

D. High temperature shut down switch and temper-

ature s ender located on the water pump housing.

E. Fuel stop solenoid on injector pump.

F. Negative battery cable and harness ground from

injector pump (Fig. 12).

G. Glow plug strip.

11.Remove engine from machine:

A. Attach short section of chain between lift tabs lo-

cated on each end of the c ylinder head.

B. Connect a hoist or chain fall at the c enter of the

short section of chain. Apply enough tension on the

short chain so that the engine will be supported.

C. Remove fasteners that secure the engine (with

brackets) to the engine mounts.

CAUTION

One person should operate lift or hoist while

another person guides the engine out of the ma-

chine.

IMPORTANT: Make sure to not damage the engine,

fuel hoses, hydraulic lines, electrical harness, ra-

diator,batteryor otherpartswhile removingthe en-

gine.

D. Raise engineandremovetoward front of machin-

e.

12.If necessary, remove engine brackets from engine.

Installation (Fig. 9)

1. Locate machine on a level surface with c utting units

lowered and key removed from the ignition switch.

Chock wheels to keep the machine from moving.

2. Make sure that all parts removed from the engine

during maintenance or rebuilding are installed to the en-

gine.

3. If engine brackets were removed from the engine,

secure brackets to engine with lock washers and cap

screws. Torque cap screws from 34 to 42 ft--lb (47 to

56 N--m).

4. Install engine to m achine.

A. Attach short section of chain between lift tabs lo-

cated on each end of the c ylinder head

B. Connect a hoist or chain fall at the c enter of the

short section of chain. Apply enough tension on the

short chain so that the engine can be supported.

CAUTION

One person should operate lift or hoist while

another other person guides the engine into the

machine.

IMPORTANT: Make sure to not damage the engine,

fuel hoses, hydraulic lines, electrical harness, ra-

diator,batteryor otherparts while installing the en-

gine.

C. Lower engine to the machine frame. Make sure

fastener holes of the engine brackets are aligned

with the holes in the engine mounts.

D. Insert cap screw down through each engine

bracket and m ount. Place spacer, snubbing washer

and then flange nut on four (4) cap screws. Tighten

fasteners to secure engine to engine mounts.

5. Connect hydraulic transmission driveshaft to engine

(see Hydraulic Transmission Drive S haft Installation in

the Service and Repairs section of Chapter 4 -- Hydrau-

lic System).

6. Connect all wire harness connectors to correct en-

gine c omponents.