Reelmaster 5010 Series Hydraulic System (Rev. C)Page 4 -- 9

Traction Circuit

The hydraulic traction circuit consists of a variable dis-

placementpistonpump(P5) connectedinaclosedloop,

parallelcircuittotwo (2)orbitalrollervane wheelmotors.

The traction pump input shaft is rotated by a drive shaft

that is driven from the engine flywheel.

Traction circuit pressure (forward and reverse) can be

measured at test ports located in the hydraulic tubes

that connect the front wheel motors.

Forward Direction (Fig. 8)

Pushing the top of the traction pedal angles the traction

pump swash plate to create a flow of oil. This oil flow is

directed to the wheel motors via hydraulic hoses and

tubes to drive the wheels in the forward direction. For-

ward traction pressure is limited to 3625 PSI (250 bar)

by the forward traction relief valve (R3) located in the

traction pump.

Oil flowing fromthe wheel motors returnsto the variable

displacement pump and is continuously pumped

through the traction circuit as long as the traction pedal

is pushed.

The angleof the swashplate determinespump flow and

ultimately traction speed.When the traction pedal isde-

pressedasmallamount, asmallswashplaterotation re-

sultsinlowpumpoutputandlowertractionspeed.When

the traction pedal is depressed fully, the pump swash

plate rotates fullyto provide maximum pump output and

traction speed.

Gear pumpsection (P3)supplies oilflow forthe steering

circuit and also provides a constant supply of charge oil

to the closed loop traction circuit. This charge oil pro-

videslubricationfortractioncircuitcomponentsandalso

replenishes traction circuit oil that is lost due to internal

leakage in the traction circuit.

Gear pump(P3) takesits suction fromthe hydraulic res-

ervoir.Charge pump flow is directedto the low pressure

side of the closed loop traction circuit. Charge pressure

is limited by the charge relief valve (R5) located in the

traction pump.Thec harge reliefpressure is200 PSI(14

bar).

The piston pump ( P5) includes a flushing valve (R10)

that bleeds off a small amount of hydraulic fluid for cool-

ingofthe closedlooptractioncircuit.The chargesystem

replenishes oilthat isbled fromthe traction circuitby the

flushing valve.

Reverse Direction

The traction circuit operates essentially the same in re-

verse as it does in the forward direction. However, the

flow through the circuit is reversed. Pushing the bottom

of the traction pedal rotates the traction pump swash

plate to create a flow of o il. This oil is directed to the

wheel motors to drive the wheels in the reverse direc-

tion. Reverse traction pressure is limited to 3625 PSI

(250bar)bythe reversetractionreliefvalve (R4)located

in the traction pump.

Oil flowing from the wheel motors returns to the traction

pump and is continuously pumped through the closed

loop traction circuit as long as the traction pedal is

pushed.

The charge circuit and flushing valve (R10) function the

same in reverse as they do in the forward direction.

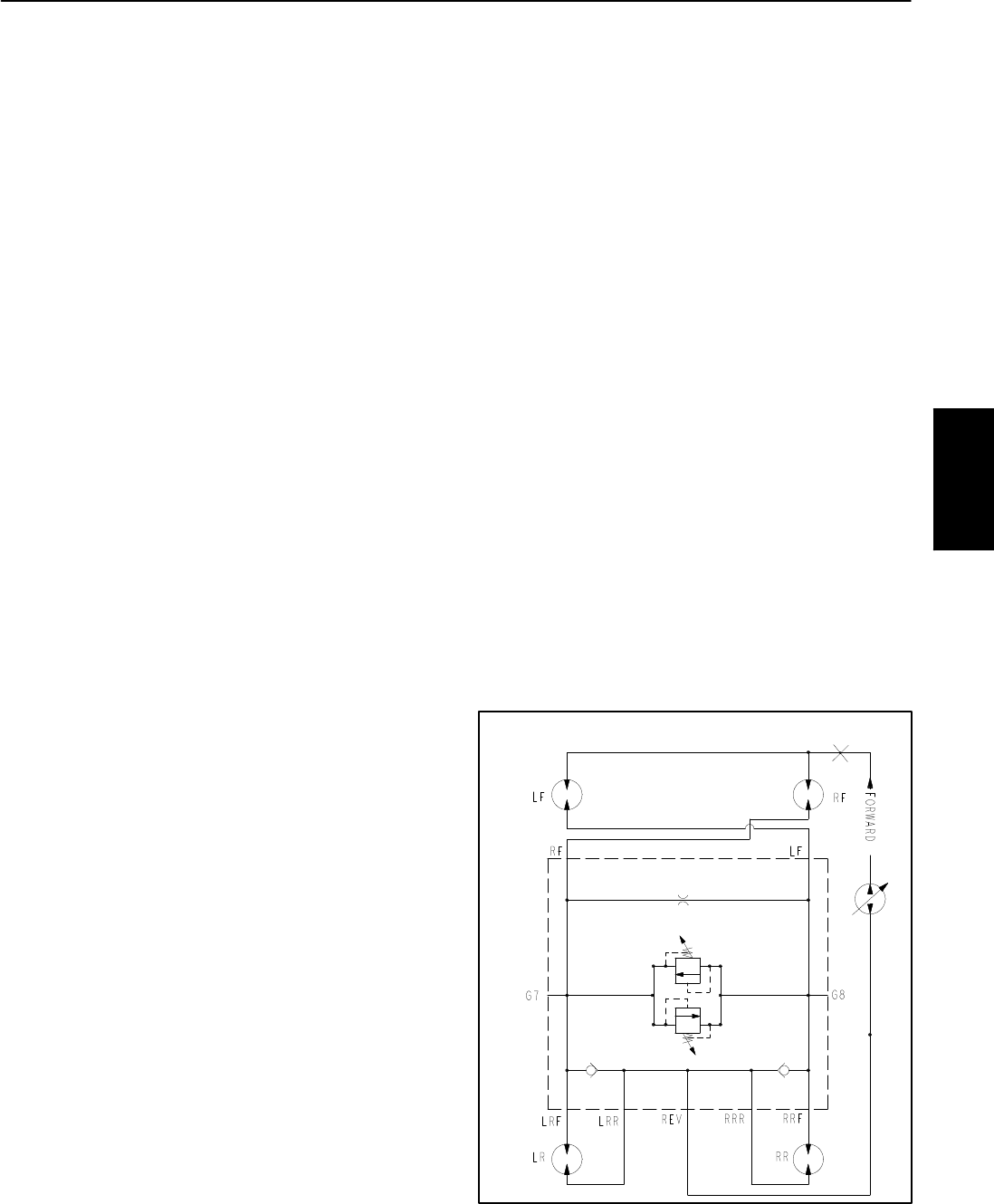

CrossTrax

TM

AWD (Optional)

On machines equipped with the optional CrossTrax

TM

AWD kit, four wheel motors are used (Fig. 9). Traction

pump flow is directed to the front tires and the opposite

rear tires to maximize traction. To reduce tire scuffing

when turning, traction system pressure is equalized in

the AWD manifoldwith anorifice anda bi--directional re-

lief valve. Check valves in the AWD manifold allow the

rear wheel motors to over run during tight turns.

Figure 9

G5

CrossTrax AWD Hydraulic Schematic

TM

Hydraulic

System