Reelmaster 5010 Series Page 5 -- 41 Electrical System

Temperature Sender

The temperature sender is attached to the water pump

housing on the engine and has a gray wire attached to

it(Fig. 53).Theresistance ofthe temperaturesenderre-

duces as the engine coolant temperature increases.

The changingresistance of thetemperature sender sig-

nals the console temperature gauge to indicate engine

coolant temperature level during machine operation.

When coolant temperature rises to approximately

221

o

F (105

o

C), temperature sender resistance causes

the temperature gauge to provide an input to the Elec-

tronic C ontrol Module (ECM). This ECM input causes

the high temperature warning light to illuminate and the

cuttingreelsto shutdown.The temperaturegauge,tem-

perature sender and circuit wiring should be tested as

an ECM input with the Diagnostic Display (see Special

Tools and Troubleshooting in this chapter).

Iftheexcessive coolanttemperaturecaused theECMto

shut down the cutting reels, the Diagnostic light can be

used to identify the fault (see Diagnostic Light in the

Troubleshooting section of this chapter).

Testing

1. Park machine on a level surface, lower cutting units,

stop engine, apply parking brake and remove key from

ignition switch. Open hood to gain access to engine.

CAUTION

Make sure engine is cool before removing the

temperature sender from engine.

2. Lower the coolant level in the engine, remove wire

harness connector from temperature sender and re-

move the sender from the engine.

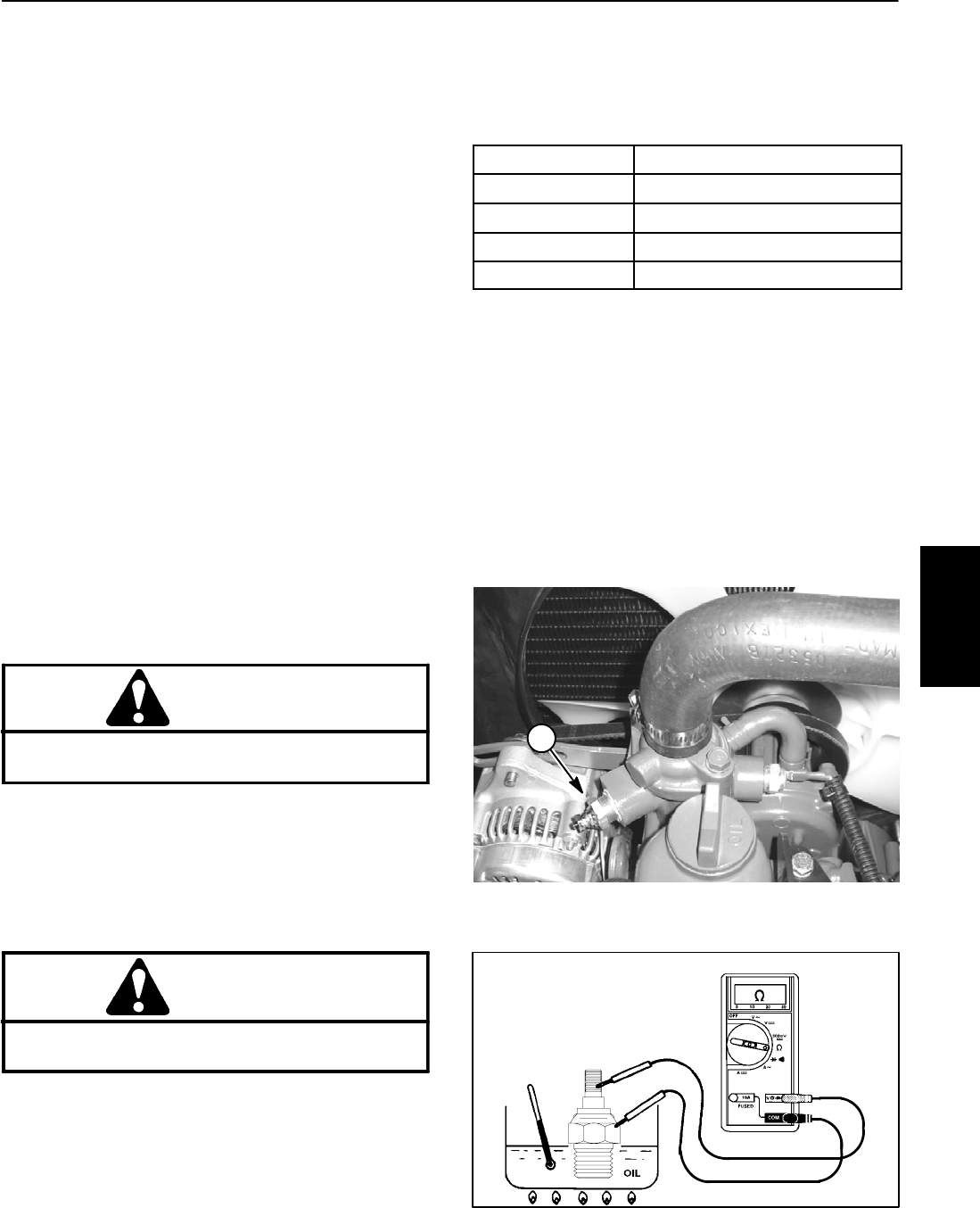

3. Put the end of the sender in a container of oil with a

thermometer and slowly heat the oil (Fig. 54).

CAUTION

Handle the hot oil with extreme care to prevent

personal injury or fire.

NOTE: Prior to taking resistance readings with a digital

multimeter,s hort the meter test leadstogether. The me-

ter will display a small resistance value (usually 0.5

ohms or less). This resistance is due to the internal re-

sistance of the meter and test leads. Subtract this value

fromfrom themeasuredvalueof thecomponent youare

testing.

4. Check resistance of the sender with a multimeter

(ohms setting) as the temperature increases. Replace

sender if specifications are not met.

COOLANT TEMP

TEMP SENDER RESISTANCE

100

o

F(38

o

C) 460 ohms (approximate)

160

o

F(71

o

C) 140 ohms (approximate)

200

o

F(93

o

C) 54 to 78 ohms

221

o

F (105

o

C) 50 ohms (approximate)

5. After testing, install sender to the engine housing.

A. Clean threads ofhousing and sender thoroughly.

Apply thread sealant to the threads of the sender.

B. Thread sender into the housing. Torque sender

from 16 to 20 ft--lb (22 to 27 N--m).

C. Reconnect harness wire connector to sender.

6. Fill engine cooling system.

7. Lower and secure hood.

1. Temperature sender

Figure 53

1

Figure 54

Electrical

System