Reelmaster 5010 Series Hydraulic System (Rev. C)Page 4 -- 69

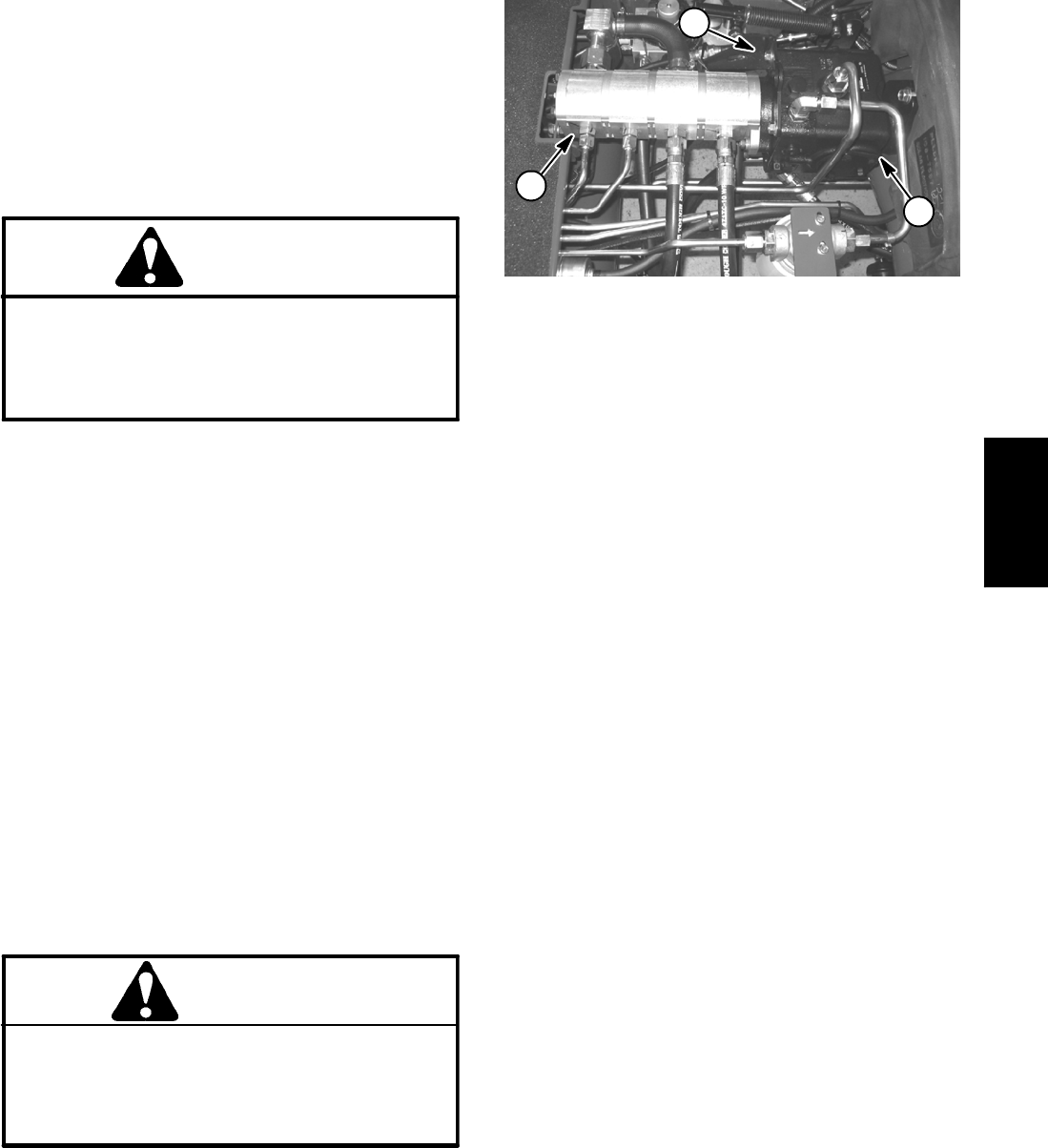

Removal (Fig. 60)

1. Parkthe machineona levelsurface, engageparking

brake, lower cutting units and stopengine. Remove key

from the ignition switch.

2. Read the General Precautions for Removing and

Installing Hydraulic System Components at the begin-

ning of the Service and Repairs section of this chapter.

CAUTION

Before openinghydraulic system, operateall hy-

draulic controls to relieve system pressure and

avoid injury from pressurized hydraulic oil. See

Relieving HydraulicSystemPressure inthe Gen-

eral Information section of this chapter.

3. To prevent contamination of the hydraulic system,

thoroughly clean traction and gear pump assembly and

all hydraulic connections.

4. Label hydraulic hoses toassist in assembly. Discon-

nect all hydraulic hoses and tubes from fittings on the

traction and gear pump assembly. Allow hydraulic lines

to drain into a suitable container. Plug or cap openings

of pumps and lines to prevent contamination.

5. Remove hydraulic pump drive shaft (see Hydraulic

Pump Drive Shaft Removal in this section).

6. Remove cap screw and lock nut that secure plate

(item 10) to pump lever. Remove two (2) flange head

screws (item 3) that secure cable bracket to traction

pump. Carefully position traction control cable and

bracket away from traction pump.

7. Disconnect harness electrical connector from trac-

tion neutral switch and position harness away from

transmission.

CAUTION

Make sure lift or hoist can support the total

weight of the pump assembly before removing

the cap screws from the engine and engine

brackets.Pump assemblyweighsapproximately

67 pounds (30.5 kg).

8. Connecta liftor hoistto holein tractioncable bracket

on traction pump to s upport pump assembly and for

pump removal.

9. Loosen and remove two (2) carriage screws (item

38) and flange nuts (item 36) that secure pump support

bracket to frame.

1. Piston (traction) pump

2. Gear pump

3. Traction cable bracket

Figure 61

2

1

3

10.Remove two (2) flange screws and flange nuts that

secure traction pump flange to machine frame.

IMPORTANT: Make sure to not damage machine

components while removing the pump assembly.

11.Carefully lift pump assembly from the machine.

12.Remove two (2) socket head screws, lock washers

and flat washers that secure gear pump to traction

pump. Remove gear pump from traction pump. Locate

and discard O--ring (item 30) from between pumps.

13.If necessary, remove hydraulic fittings from pumps.

Note orientation of fittings for assembly purposes.

14.If necessary, remove two (2) lock nuts (item 35) that

secure pump support bracket (item 37) to gear pump.

Remove bracket and two (2) flat washers from gear

pump.

15.Remove and discard all O--rings from removed hy-

draulic lines and fittings.

Installation (Fig. 60)

1. If fittings were removed from pump assembly, lightly

lubricate new fitting O--rings with clean hydraulic oil.

Install fittings with O--rings to the pump assembly (see

Hydraulic Fitting Installation in the General Information

section of this chapter). Orientate fittings as noted dur-

ing removal.

2. Ifpump support bracket(item 37) wasremoved from

gear pump, fit flat washers and bracket to gear pump

and secure with two (2) lock nuts.

3. Lubricate and position new O--ring (item 30) be-

tween pumps. Position gear pump to traction pump and

secure with two (2) socket head screws, lock washers

and flat washers.

IMPORTANT: Make sure to not damage machine

components while installing the pump assembly.

Hydraulic

System