Reelmaster 5010 Series

Cutting Units (Rev. C)

Page 7 -- 19

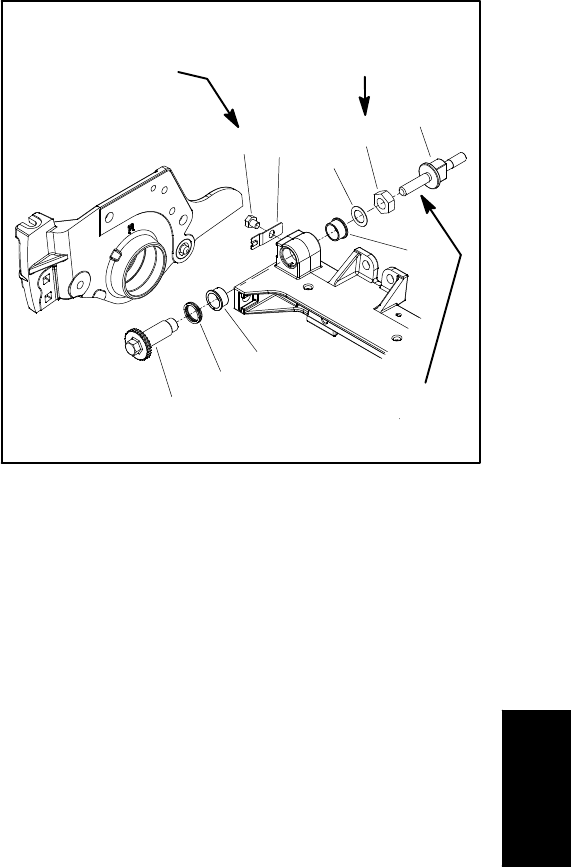

Removal (Fig. 21)

1. Remove lock nut (item 3), compression spring (item

2) and washer (item 11) from bedbar adjuster screw

(item 10).

2. Remove bedbar (see Bedbar Removal in this sec-

tion).

NOTE: Inside threads in bedbar adjuster shaft (item 4)

are left--hand threads.

3. Unscrew bedbar adjuster screw (item 10) from the

bedbar adjuster shaft (item 4).

4. Remove adjuster shaft from cutting unit frame:

A. On early production cutting units (Fig. 21), re-

move retaining ring and wave washer from adjuster

shaft. Slide adjuster shaft from cutting unit frame.

B. On current production cutting units (Fig. 22), re-

move lock nut and flat washer from adjuster shaft.

Slide adjuster shaft and wave washer from cutting

unit frame.

5. Inspect flange bushings (item 5) in cutting unit frame

and remove if necessary.

6. If detent (item 7) is damaged, remove it from cutting

unit side plate by removing the cap screw (item 6).

Installation (Fig. 21)

1. If detent (item 7) was removed, apply Loctite #242

(or equivalent) to threads of cap screw (item 6) and se-

cure detent to cutting unit side plate with cap screw.

Torque cap screw from 14 to 16 ft--lb (19 to 21 N--m).

2. Ifflange bushings (item5) wereremoved, applyanti-

seize lubricantto bore ofcutting unit frame.Align key on

bushing to slot in frame and install bushings into frame.

3. Install adjuster shaft to cutting unit frame:

A. On early production cutting units (Fig. 21), slide

bedbar adjuster shaft into flange bushings in cutting

unit frame. Secure adjuster shaft with wave washer

and retaining ring.

B. Oncurrentproductioncutting units(Fig.22),slide

wave washer onto adjuster shaft and then slide ad-

juster shaftintoflange bushingsin cuttingunit frame.

Secure adjuster shaft with flat washer and lock nut.

Tighten lock nut to shoulder of adjuster s haft and

then torque lock nut from 15 to 20 ft--lb (21 to 27

N--m).

NOTE: Inside threads in bedbar adjuster shaft (item 4)

are left--hand threads.

4. Applyantiseizelubricant tothreadsof bedbaradjust-

erscrew(item10) thatfitintoadjustershaft.Threadbed-

bar adjuster screw into adjuster shaft (item 4).

5. Install bedbar (see Bedbar Installation in this sec-

tion).

6. Installwasher (item 11), compression spring(item 2)

and lock nut (item 3) onto adjuster screw. Tighten the

lock nut on each bedbar adjuster assembly until the

compression spring is fully compressed, then loosen

lock nut 1/2 turn.

7. Adjust cutting unit (see Cutting Unit Operator’s

Manual).

1. Bedbar adjuster screw

2. Lock nut

3. Flat washer

4. Flange bushing

5. Cap screw

6. Detent

7. Wave washer

8. Bedbar adjuster shaft

Figure 22

Antiseize

Lubricant

14 to 16 ft--lb

(19to21N--m)

Loctite #242

4

6

7

5

4

3

2

1

8

15 to 20 ft--lb

(21to27N--m)

DPA Cutting

Units