Greensmaster eFlex 1800/2100Traction and Reel Drive System Page 3 -- 38

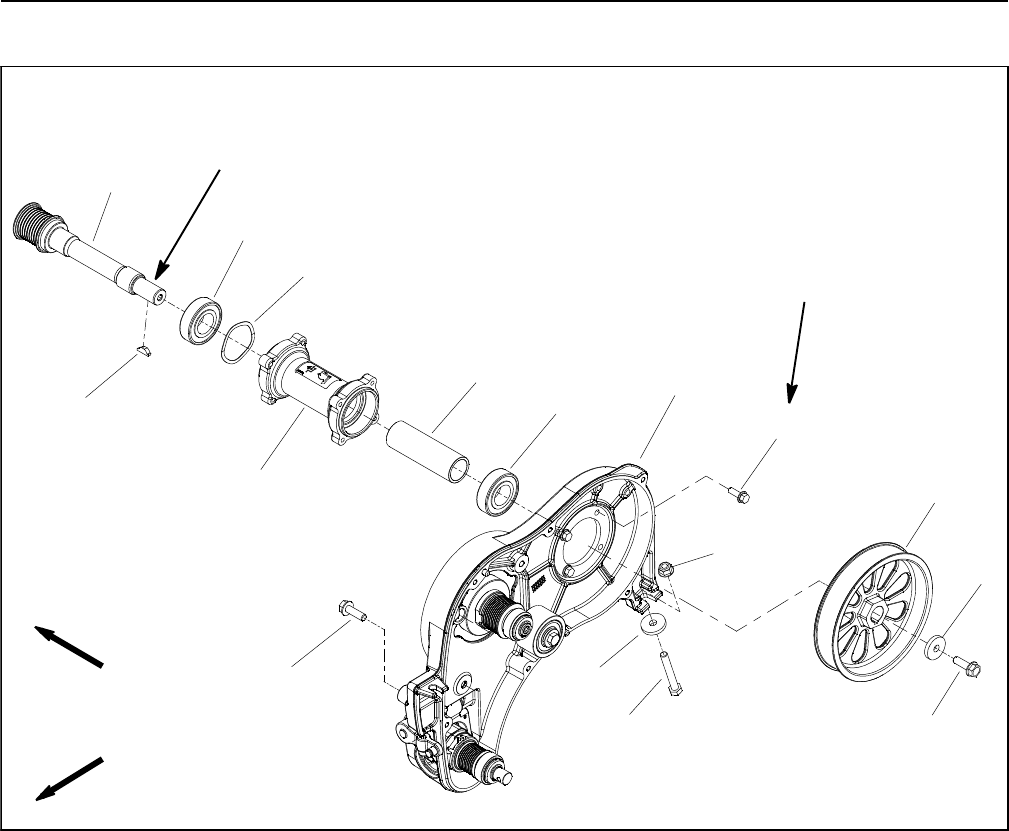

Transmission Drum Drive System

Figure 45

1. Transmission housing

2. Extension housing

3. Ball bearing (2 used)

4. Driven pulley (traction drum drive)

5. Hardened washer (2 used)

6. Driven pulley

7. Spacer

8. Wave washer

9. Woodruff key

10. Washer head screw (4 used)

11. Flange nut

12. Flange head screw (2 used)

13. Cap screw

FRONT

RIGHT

6

5

5

2

4

3

3

1

7

8

9

10

11

12

12

13

See text for

tightening

procedure

Lubricant

Antiseize

Transmission removal from the machine is not neces-

sary to service the transmission drum drive system

shown in Figure 45. Transmission drum drive compo-

nents can be accessed by removing the battery pack

from the frame, removing the transmission cover and

then removing the drive belt.

Disassembly (Fig. 45)

1. Parkmachineon level surface. Turnkeyswitch to the

OFF position and remove key from the switch. Discon-

nect the battery pack (see Battery Pack Connection in

the General Information section of this chapter).

2. Remove transmission drive belt (see Transmission

Drive Belt in this section).

3. Remove flange head screw (item 12) and hardened

washer (item 5) t hat secure driven pulley (item 6) to

shaft. Slide pulley from shaft. Locate and retrieve wood-

ruff key (item 9).

4. Remove drum drive belt from machine (see Drum

Drive Belt in this section).

5. Slide traction d rum drive driven pulley (item 4) from

extension housing.

6. If necessary, remove ball bearings (item 3), spacer

(item 7) and wave washer (item 8) from extension hous-

ing.