Greensmaster eFlex 1800/2100Page 6 -- 22Cutting Unit

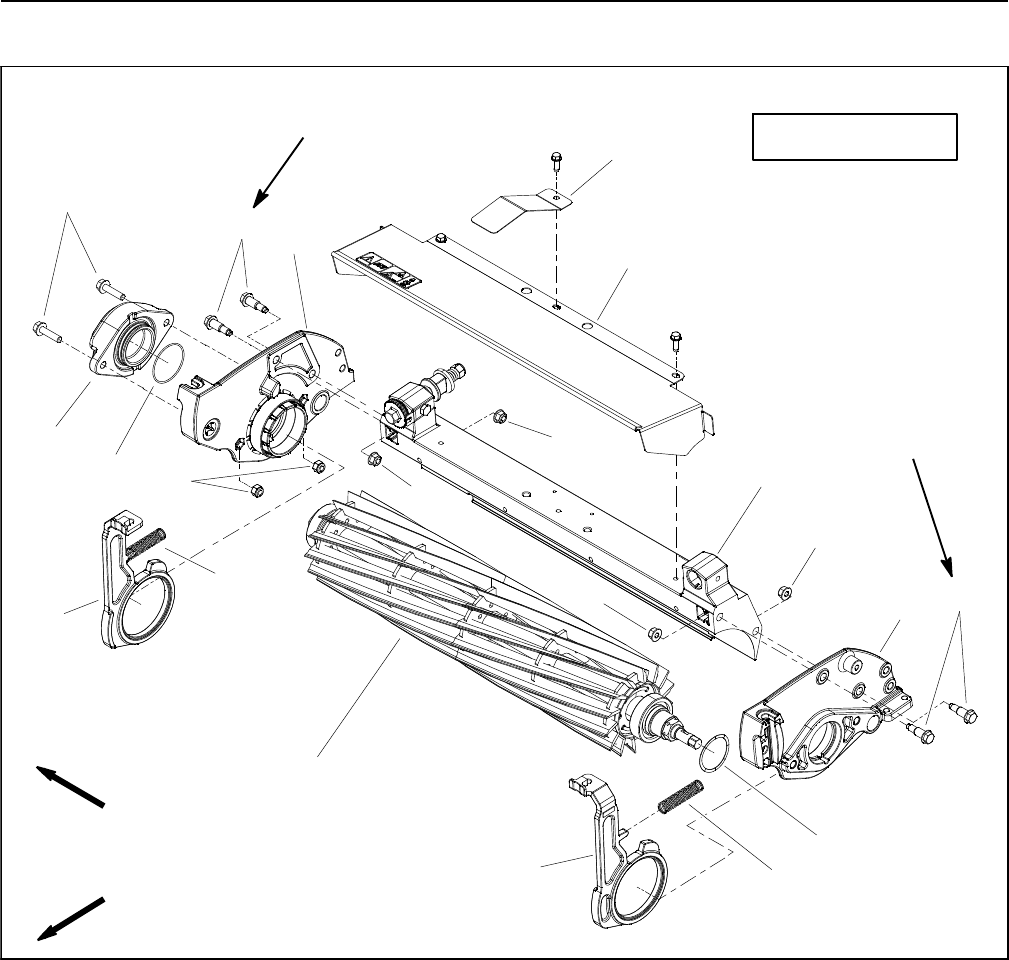

Cutting Reel Assembly Removal and Installation

1. Crossmember

2. LH side plate

3. Compression spring (2 used)

4. Shoulder bolt (2 used per side plate)

5. Flange nut (2 used per side plate)

6. Cutting reel assembly

7. RH pitch arm

8. Flange head screw (2 used)

9. RH side plate

10. Weight

11. Hex nut

12. O--ring

13. Grass shield

14. Flat wire spring

15. LH pitch arm

16. Sensor target plate

Figure 34

FRONT

RIGHT

210 to 240 in--lb

(24to27N--m)

4

2

9

5

13

1

4

5

5

5

7

11

3

210 to 240 in--lb

(24 to 27 N--m)

6

14

8

10

12

3

15

16

eFlex2100Shown

NOTE: This section provides the procedure for remov-

ing and installing the cutting reel assembly (cutting reel,

flocked seals, reel bearings,bearing lock screwand reel

nut) from the cutting unit. Refer to Cutting Reel Assem-

bly Service in this section for information on servicing

the cutting reel assembly.

NOTE: EFlex 2100 cutting units use shoulder bolts

(item 4)and flangenuts (item 5) tosecure theside plates

to the crossmember as shown in Figure 34. On eFlex

1800 cutting units, square nuts are used instead of

flange nuts. Cutting unit service procedures are the

same on both models.