Greensmaster eFlex 1800/2100 Page 4 -- 47 Electrical System

8. Remove and discard O--ring (item 8) from motor

housing.

IMPORTANT: Make sure to not damage the gearbox

cover counter bore when removing the shaft seal

from the cover.

9. Carefully remove shaftseal from gearbox cover. Dis-

card removed seal.

10.If necessary, remove bearings from output gear

(item 11) and rotor (item6).Discardbearingsifremoved.

11.Inspect grease in output gear area of motor housing.

If grease is clean and not contaminated, it can remain in

housing. If grease is contaminated, clean grease from

housing and replace with 15ml of NLGI grade 00 grease

during motor assembly.

12.Inspect motor components for wear or damage. Re-

place components or complete electric motor assembly

if necessary.

Assembly (Fig. 58)

1. Make sure that all motor components are cleaned

before assembly.

2. If bearings were removed from output gear (item 11)

and rotor (item 6) install new bearings. Make sure that

bearings are fully pressed onto shafts.

3. Lubricate new inner O--ring (item 8) with dielectric lu-

bricant (see Special Tools in this chapter) and install O--

ring into rear of motor housing.

IMPORTANT: The rotor magnets are very powerful

and can cause the rotorto shift position very rapidly

during installation. Be cautious during rotor install-

ation to prevent component damage or personal in-

jury.

4. Use electric motor rotor tool set (see Special Tools in

this chapter) to carefully install rotor assembly (items 5,

6 and 7) into motor housing.

5. Lubricate new O--rings (items 14 and 3) with dielec-

tric lubricant (see Special Tools in this chapter) and

install O--rings to grooves in motor cover. Place wave

washer (item 4) in cover.

6. Carefully slide motor cover onto r otor until it contacts

motor housing. Secure cover with six (6) torx head

screws.

7. Make sure that rotor rotates before continuing with

motor a ssembly.

8. Placewavewasher(item 4) into housing bore for out-

put gear bearing.

9. Make sure that output gear area of motor housing

has clean grease remaining in housing. If grease was

cleaned from housing, install 15ml of new NLGI grade

00 grease into housing during motor assembly.

10.Slide output gear assembly (items 5, 11 and 7) into

front of housing. Make sure that output gear teeth mesh

with rotor gear.

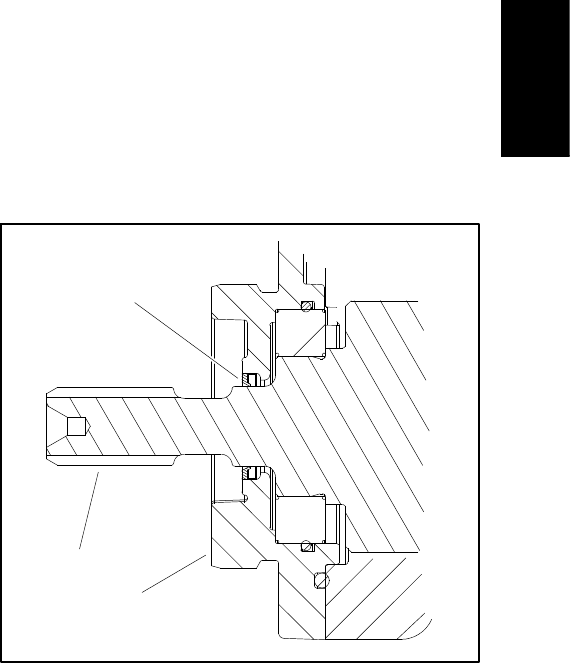

11.Install shaft seal (item 13) into gearbox cover. Press

shaft seal into front cover until it is flush with the cover

surface. Shaft seal should have the seal lip toward the

inside of the motor (Fig. 59).

12.Lubricate new O--rings (items 8 and 10) with dielec-

tric lubricant (see Special Tools in this chapter) and

install O--rings to grooves in gearbox cover.

IMPORTANT: Make sure to not damage the shaft

seal when installing the gearbox cover.

13.Carefully slide gearbox cover onto output gear s haft

until it contacts motor housing. Secure cover with six (6)

torx head screws.

14.Torque all torx screws (item 1) on gearbox cover and

motor cover from 35 to 45 in--lb (4 to 5 N-- m).

1. Output gear

2. Gearbox cover

3. Shaft seal

Figure 59

3

2

1

Electrical

System