Greensmaster eFlex 1800/2100 Page 6 -- 27 Cutting Unit

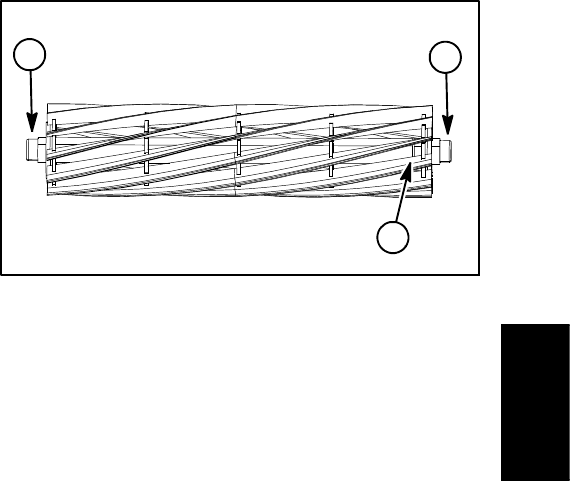

Disassembly of Cutting Reel (Fig. 37)

IMPORTANT: When removing reel drive shaft (item

4), use appropriate wrench or socket on 1” hex sur-

face of shaft. Do not use 1/2” extension on end of

reel drive shaft when loosening or tightening drive

shaft. The 1/2” hex is intended for backlapping only.

1. Remove bearing lock screw (item 5) and reel drive

shaft (item 4) from cutting reel. Reel drive shaft has LH

threadsand is in end ofreelshaft identified with a groove

that is just inside of reel spider (Fig. 38).

2. Slide bearings from reel shaft.

3. Note orientation of flocked seals for assembly pur-

poses. Remove seals from reel shaft.

Inspection of Cutting Reel (Fig. 37)

1. Inspect reel bearings to insure that they spin freely

and have minimal axial play.

2. Inspectthe reel shaft as follows. Ifreel damage is de-

tected, replace cutting reel.

A. Check the reel shaft for bending and distortion by

placing the shaft ends in V--blocks.

B. Check the reel blades for bending or cracking.

C. Check the service limit of the reel diameter (see

Preparing a Reel for Grinding in this section).

D. Check threads in ends of reel shaft.

3. Check the woodruff key slot and hex drive on the reel

drive shaft (item 4) for excessive wear or distortion. Re-

place drive shaft if damage is evident.

Assembly of Cutting Reel (Fig. 37)

1. If bearings and/or flocked seals were removed from

reel shaft, discard removed components and r eplace.

IMPORTANT: The flocked seal should be installed

so the flocked side of the seal is toward the bearing

location.

2. Press flocked seals onto reel shaft with flocked side

orientated toward bearing location. Seal should be per-

pendicular to reel shaft after installation.

3. Slide bearings fully onto reel shaft. Bearings should

bottom on reel shaft shoulder.

IMPORTANT: When installing reel drive shaft (item

4), use appropriate wrench or socket on 1” hex sur-

face of shaft. Do not use 1/2” extension on end of

reel drive shaft when loosening or tightening drive

shaft. The 1/2” hex is intended for backlapping only.

4. Installbearinglock screw (item 5)andreel drive shaft

(item 4) into reel shaft to secure bearings. Reel drive

shaft has LH threads and should be installed in end of

reelshaftidentifiedwithagroove thatis just inside ofreel

spider (Fig. 38).

NOTE: Installation torque for bearing lock screw and

reel drive shaftis from 90 to 110 ft--lb (123 to 149 N--m).

It is easiest to torque these items after the cutting reel is

installed in the cutting unit frame (see Reel Assembly

Removal and Installation in this section).

1. LH threads

2. Groove

3. RH threads

Figure 38

1

2

3

Cutting Unit