Greensmaster eFlex 1800/2100 Traction and Reel Drive SystemPage 3 -- 11

Service and Repairs

Reel Drive Belt

EFlex machines use a positive drive belt on the left side

of the machine to operate the cutting u nit.

Removal

1. Parkmachineonlevelsurface.Turnkeyswitchtothe

OFF position and remove key from the switch. Discon-

nect the battery pack (see Battery Pack Connection in

the General Information section of this chapter).

2. Remove reel drive cover to expose reel drive belt

(Fig. 14).

3. Loosen the bearing housing mounting nut (Fig. 15).

4. Using a 5/8” (16mm) wrench, rotate the bearing

housing to release tension on reel drive belt (Fig. 15).

5. Remove reel drive b elt from the pulleys.

Installation

1. Make sure that the battery pack is disconnected (see

Battery Pack Connection in the General Information

section of this chapter).

2. Using a 5/8” (16mm) wrench, rotate and hold the

bearing housing to allow reel drive belt installation (Fig.

15).

3. Place a new drive belt onto the pulleys.

4. Release bearing housing to apply tension to reel

drive belt. Make sure that bearing housing rotates freely

which will allow accurate belt tension.

5. Rotate reel drive at least one (1) full turn to ensure

that drive belt is properly tensioned.

6. Tighten the bearing housing mounting nut (Fig. 15).

7. Install reel drive cover to machine and secure with

flange head screw (Fig. 14).

8. Connectthe battery pack(see Battery Pack Connec-

tion in the General Information section of this chapter).

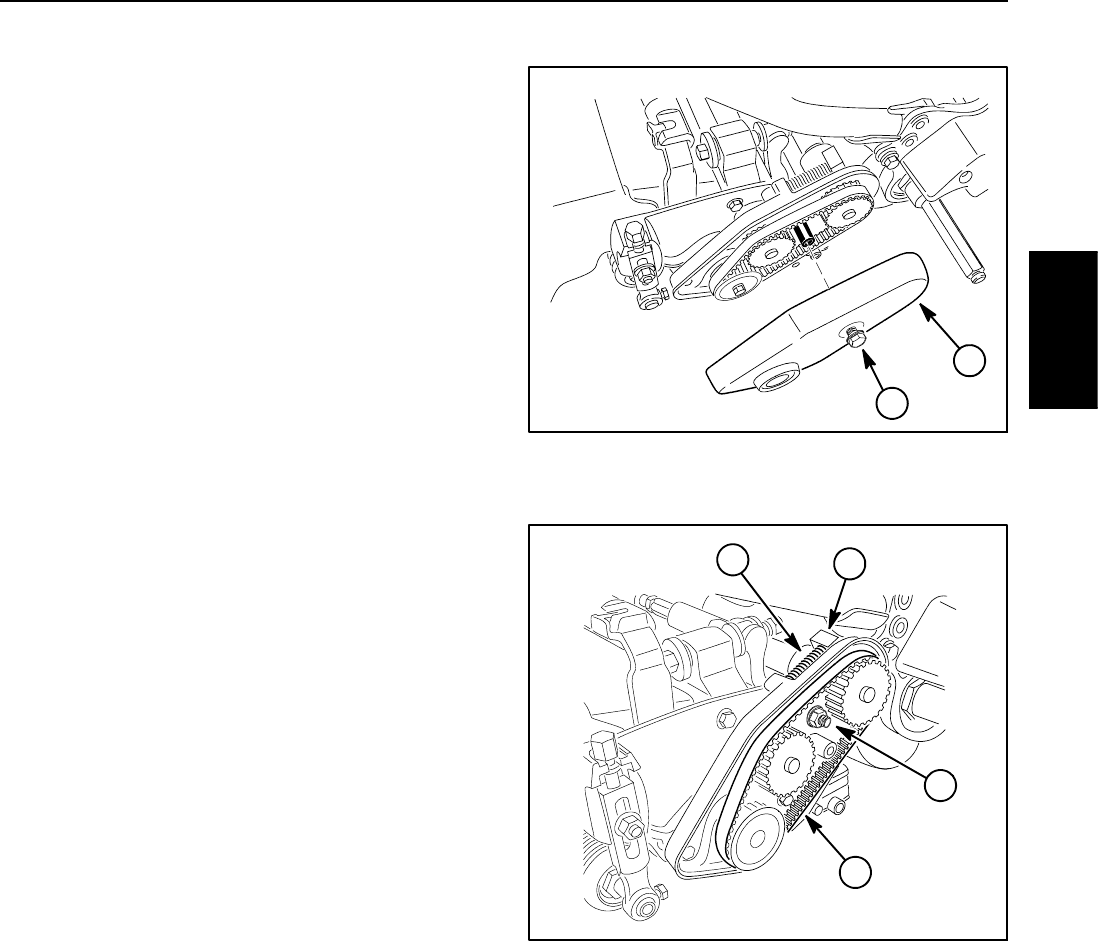

1. Reel drive cover 2. Flange head screw

Figure 14

1

2

1. Reel drive belt

2. Bearing housing nut

3. Compression spring

4. Bearing housing

Figure 15

1

2

3

4

Traction and Reel

Drive System