Engine

20

Tractors,

Lawn

and

Garden

-

110

and

112

SM-2059-(Apr-67)

Cylinder

Head

and

Valves

-

Tecums

eh

30-7

HI

GHT

/'rf .'.

,;~;

9

Fig.

18-Yalve

and

Seal

Relationship

Lift

valve

from

seat

eve

ry

eight

or

ten

strokes

to

keep

compound

e

qualized

on

surface

of

valve

seat.

Continue

v

al

ve

lapping

operation

until

a

uniform

lapping

ring

appea

r S

around

enti

re

su

r-

face

of

valve

face.

When

a g

ood

surface

is

attain-

ed,

wash

all

parts

with

s

olvent

to

remove

all

tra

ces

of

lapping

compound.

Dry

parts

thor-

oughly.

Note

position

of

valve

seat

marked

on

valve

face.

Th

e

lappin

g

mark

made

by

the

seat

aft

er

lapping

should

appear

on

or

near

the

center

of

the

va

1

ve

face.

REAMING

VALVE

GUTDES

If

valve

guid

e

clearance

exceeds

maximum

tolerance,

ream

the

guid

e.

When

matching

valves

to

seats,

be

sur

e

valve

seat

is

very

nearly

centered

on

the

valve

face.

The

pOSition

of

the

valve

in

the

seat

is

clearly

evident

a

fter

lapping

th

e

valve,

Figur

e 18.

\ '

ah

'e

Lapping

•

f.(

U

TI I I

Fig.

19-Lapping

Yo/

ve·s

Coat

fac

e of

valve

sparingly

with

a

fin

g

rade

of

valve

grinding

compound.

Us

e a

vacuu

m

cup

tool,

Figure

19,

to

grip

top

of

valve.

Rotate

valve

in

an

oscillating

circular

motion

on

valve

seat.

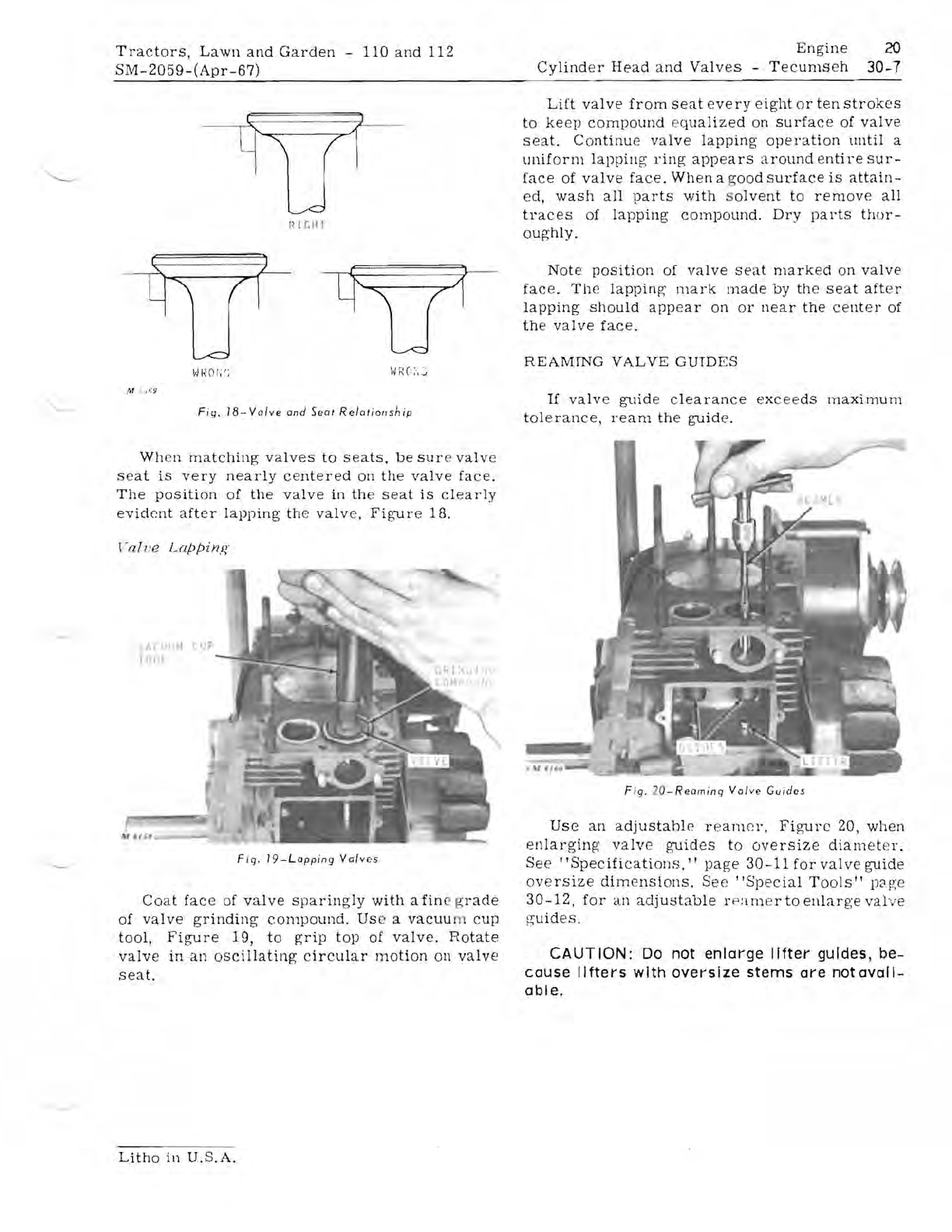

Fig.

20

-

Reoming

Valve

Guides

Use

an

adjustahl

e

ream

el',

Figure

20,

when

en

larging

valve

guides

to

oversize

diamet

e

r.

Se e

"Specification

s

,"

page

30-11

for

valve

guide

oversize

dimensions.

See '

'Special

Tools"

p3

p;

e

30-12,

for

an

adjustable

r e

amer

to

enlar

ge

va

l

ve

g;uides.

CAUTION:

Do

not

enlarge

lifter

guides,

be-

cause

lifters

with

oversize

stems

are

notavall-

able.

Litho

in

U.S.A.