Tractors,

Lawn

and

Garden

-

110

and

112

Electrical

System

40

SM-2059-(Apr-57)

Charging

System

15-3

Test

Conclusions

1.

Rated

current

draw

at

rated

speed,

as

found

in

specifications,

indicates

normal

condition

of

the

motor-generator.

2.

Low

free

speed

and

high

current

draw

in-

dicates:

(a)

Too

much

friction-tight,

dirty

or

worn

bearings,

bent

armature

shaft

or

loose

pole

shoes

allowing

armature

to

drag.

(b)

Shorted

armature.

Check

on

a

growler

after

disassembly.

(c)

Grounded

armature

or

fields.

Check

further

after

disassembly.

3.

Failure

to

operate

with

high

current

draw

indicates:

(a)

Direct

ground

in

the

terminal

or

fields.

4.

No

current

draw

indicates:

(a)

Open

field

circuit.

Check

after

dis-

assembly

by

inspecting

internal

con-

nections

and

tracing

circuit

with

a

test

lamp.

(b)

Open

armature

coils.

Inspect

the

com-

mutator

for

badly

burned

bars

after

disassembly.

(c)

Broken

brush

springs,

worn

brushes,

high

insulation

hetween

the

commutator

bars

or

other

causes

which

would

prevent

goo

d

contact

between

the

brushes

and

commutator.

5.

Low

no-load

speed

and

low

current

draw

indicates:

(a)

High

internal

resistance

due

to

poor

connections,

defective

leads,

dirty

commutator

and

causes

listed

under

No.4.

5.

High

free

speed

and

high

current

draw

in-

dicates

a

shorted

shunt

or

series

field

coil.

A

shorted

shunt

coil

can

be

determined

by

follow-

ing

para

grap

h 3,

page

15-5

under

"No

Output"

on

page

15-4

.

Ti

the

shunt

coil

performs

proper-

ly,

replace

the

series

coil.

7.

High

free

speed

and

near

normal

current

draw

indicates

an

open

shunt

coil.

Replace

the

coil

and

check

for

improved

performance.

8.

Noise

emanating

from

a

generator

may

be

caused

by

a

loose

mounting

or

drive

pulley.

It

can

also

be

caused

by

worn

or

dirty

bearings,

or

improperly

seated

brushes.

Dirty

bearings

may

sometimes

be

saved

by

cleaning

and

lubri-

cating,

but

worn

bearings

should

be

replaced.

Excessive

noise

may

result

if

the

brush

holder

is

bent

,

resulting

in

improper

seatin

g of

the

brush.

Such

a

brush

holder

must

be

replaced.

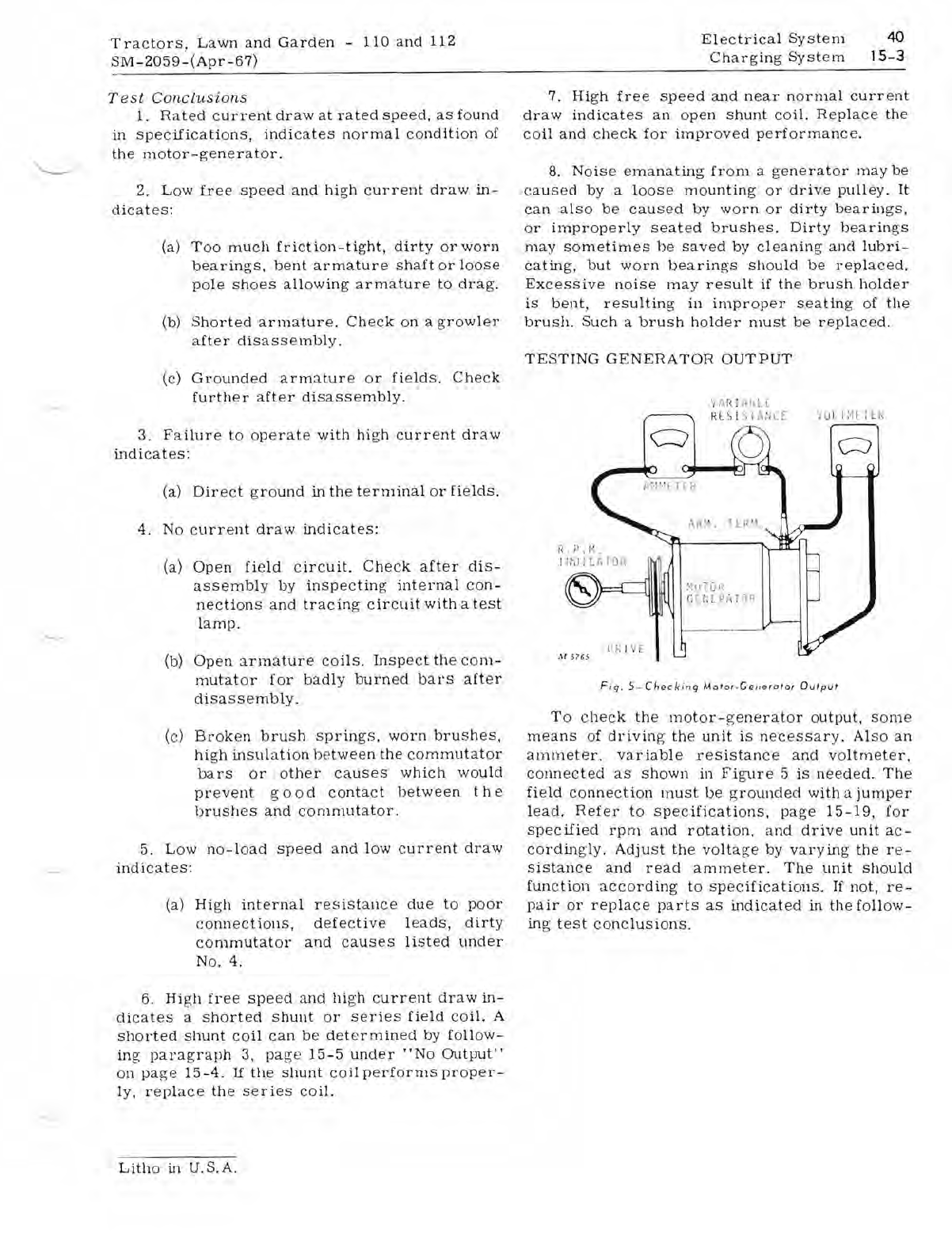

TESTING

GENERATOR

OUTPUT

{

I\r

~

.

IWL[

Rl

S

I

~lANCE

'I

tJ

L r :

'lE

r

13

DR

I

VE

M 5765

.

10

TOI!

(i

ll

oRATOR

Fi

g.

5-Checki

n9 M

oto

r-Generator

Output

To

check

the

motor-

g

enerator

output,

some

means

of

driving

the

unit

is

necessar

y.

Also

an

ammeter.

variable

resistance

and

voltmeter,

connected

as

shown

in

Figure

5

is

needed.

The

field

connection

must

be

g

rounded

with

a

jumper

lead.

Refer

to

specifications,

page

15-19,

for

specified

rpm

and

rotation.

and

drive

unit

ac-

cordin

gly.

Adjust

the

voltage

by

varying

the

re-

sistance

and

read

ammeter.

The

unit

should

function

according

to

specifications.

If

not,

re-

pair

or

replace

parts

as

indicated

in

the

follow-

ing

test

conclusions.

Litho

in U.S. A.