Tractors,

Lawn

and

Garden

-

110

and

112

SM-

2059-

(Apr-67)

Set

throttle

and

choke

valves

in

wide

open

po-

sition

by

raising

throttle

lever

all

the

way

and

lowering

choke

lever.

Install

compression

gaug~

in

cylinder,

Figure

3.

Follow

manufacturer's

recommendations

for

installing

and

reading

compression

tester.

Test

Conclusions

An

engine

in

top

operating

condition

will

read

60

to

110

psi

when

engine

is

cranked

approxi-

mately

1000

rpm.

A

compression

test

above

110

psi,

indic3tes

excessive

deposits

in

the

combustion

chamber

or

on

the

piston.

A

reading

lower

than

60

psi

indicates

leakage

a t

the

cylinder

head

gasket,

piston

rings

or

valves.

Engine

should

be

reconditioned

if

com-

pression

falls

below

60

psi.

To

determine

whether

the

rings

or

the

valves

are

at

fault,

pour

about

one

tablespoonful

of

heavy

oil

into

the

spark

plug

hole.

Crank

the

en-

gine

several

revolutions

to

spread

the

oil

and

repeat

the

compression

test.

The

oil

will

temporarily

seal

leakage

around

the

piston

rings.

If

the

same

approxim3te

com-

pression

reading

is

obtained,

the

rings

are

satis-

factory,

but

the

valves

are

leaking

or

the

piston

is

damaged.

If

the

compression

has

increased

considerably

over

the

original

readings,

there

is

leakage

past

the

rings.

CRANKCASE

VACUUM

TEST

The

crankshaft

breather

maintains

a

partial

vacuum

in

the

crankcase

when

engine

is

oper-

ating

properly.

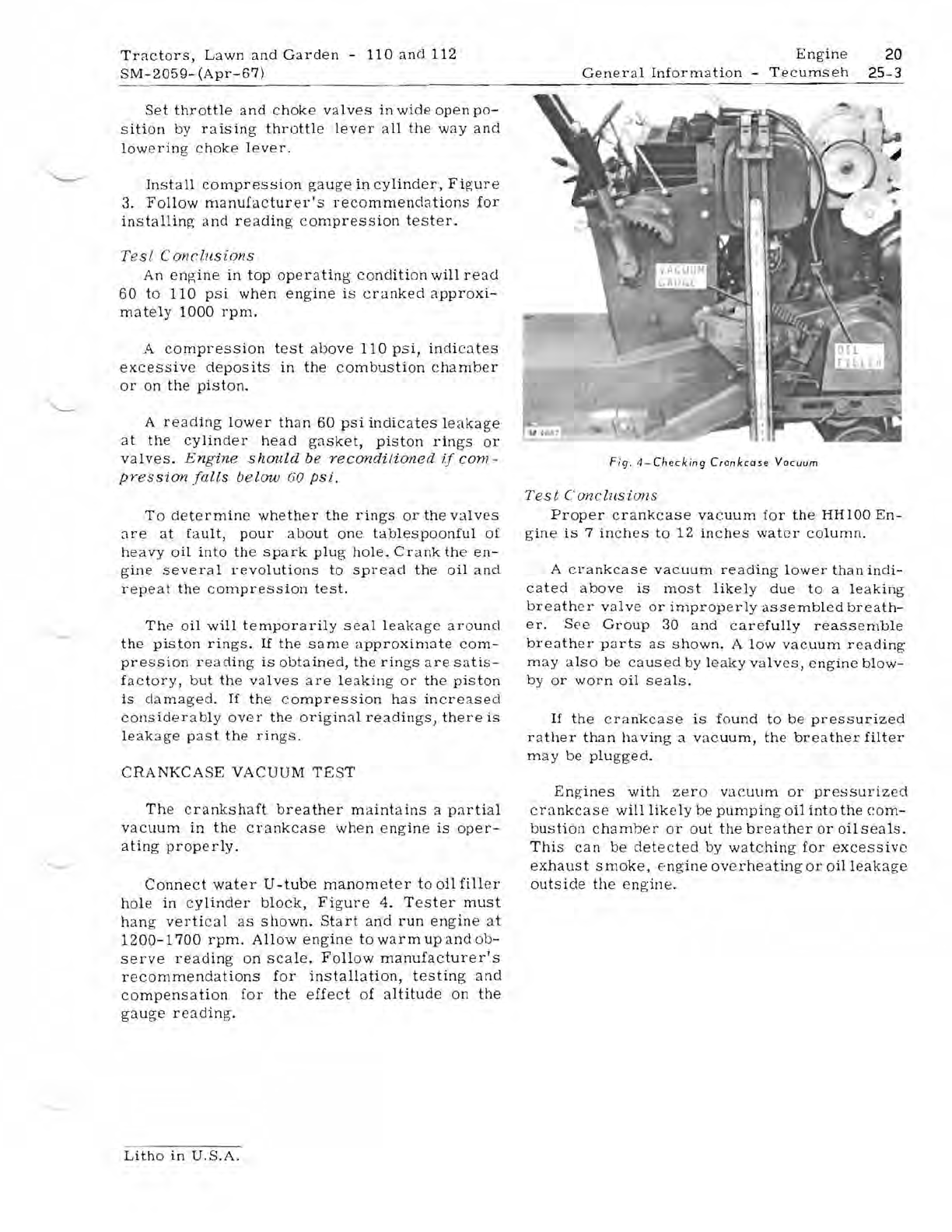

Connect

water

U

-tube

manometer

to

oil

filler

hole

in

cylinder

block,

Figure

4.

Tester

must

hang

vertical

as

shown.

Start

and

run

engine

at

1200-1700

rpm.

Allow

engine

to

warm

up

and

ob-

serve

reading

on

scale.

Follow

manufacturer's

recommendations

for

installation,

testing

and

compensation

for

the

effect

of

altitude

on

the

gauge

reading.

Engine

20

General

Information

-

Tecumseh

25-3

Fig.

-I-Checking

Crankcase

Vacuum

Test

Conclusions

Proper

crankcase

vacuum

for

the

HH

100

En-

gine

is

7

inches

to

12

inches

water

column.

A

crankcase

vacuum

reading

lower

than

indi-

cated

above

is

most

likely

due

to

a

leaking

breather

valve

or

improperly

assembled

breath-

er.

See

Group

30

and

carefully

reassemble

breather

parts

as

shown.

A

low

vacuum

reading

may

also

be

caused

by

leaky

valves,

engine

blow-

by

or

worn

oil

seals.

If

the

crankcase

is

found

to

be

pressurized

rather

than

having

a

vacuum,

the

breather

filter

may

be

plugged.

Engines

with

zero

vacuum

or

pressurized

crankcase

will

likely

be

pumping

oil

into

the

com-

bustion

chamber

or

out

the

breather

or

oil

seals.

This

can

be

detected

by

watching

for

excessive

exhaust

smoke,

engine

overheating

or

oil

leakage

outside

the

engine.

Litho

in

U.S.A.