T

ractors,

Lawn

and

Garden

-

110

and

112

Engine

20

S

M-2059-(Apr-67)

Piston,

Crankshaft

and

Flywheel

-

Tecumseh

35- 7

Be

sure

the

oil

ring

holes

are

clean.

Clean

carbon

from

piston

ring

grooves

with

a

ring

groove

cleaner,

Figure

14.

If

cleaning

tool

is

not

available,

break

an

old

ring

and

use

it

to

clean

grooves.

Fig.

IS-Measuring

Ring

Clearance

, "

.

..

Check

ring

grooves

for

excessive

wear

by

inserting

a

new

ring

in

the

proper

groove

at

several

pOints

around

the

piston.

Measure

clear-

ance

between

ring

and

groove

with

a

feeler

gauge,

Figure

15.

Refer

to

"Specifications,"

page

35-18,

for

ring

groove

side

clearance.

Replace

piston

having

ring

clearance

beyond

wear

limits.

Inspect

piston

for

fractures

at

the

ring

lands,

skirts

and

ring

bosses

and

for

rough

or

scored

skirts.

Analyze

the

condition

of

the

piston

by

stud-

ying

the

illustrations

beginning

on

page

35-8.

Replace

faulty

pistons.

,' I .101,

PI'

Fig.

16-Measuring

Piston

Pi"

and

Piston

Measure

piston

pin

to

piston

clearance

with

micrometer.

Ream

out

piston

and

rod

and

install

oversize

piston

pins

when

necessary.

See

"Spec-

ifications,"

page

35-18.

Oversize

piston

pins

are

a

vailable

for

service.

.

1f

,

t'

I

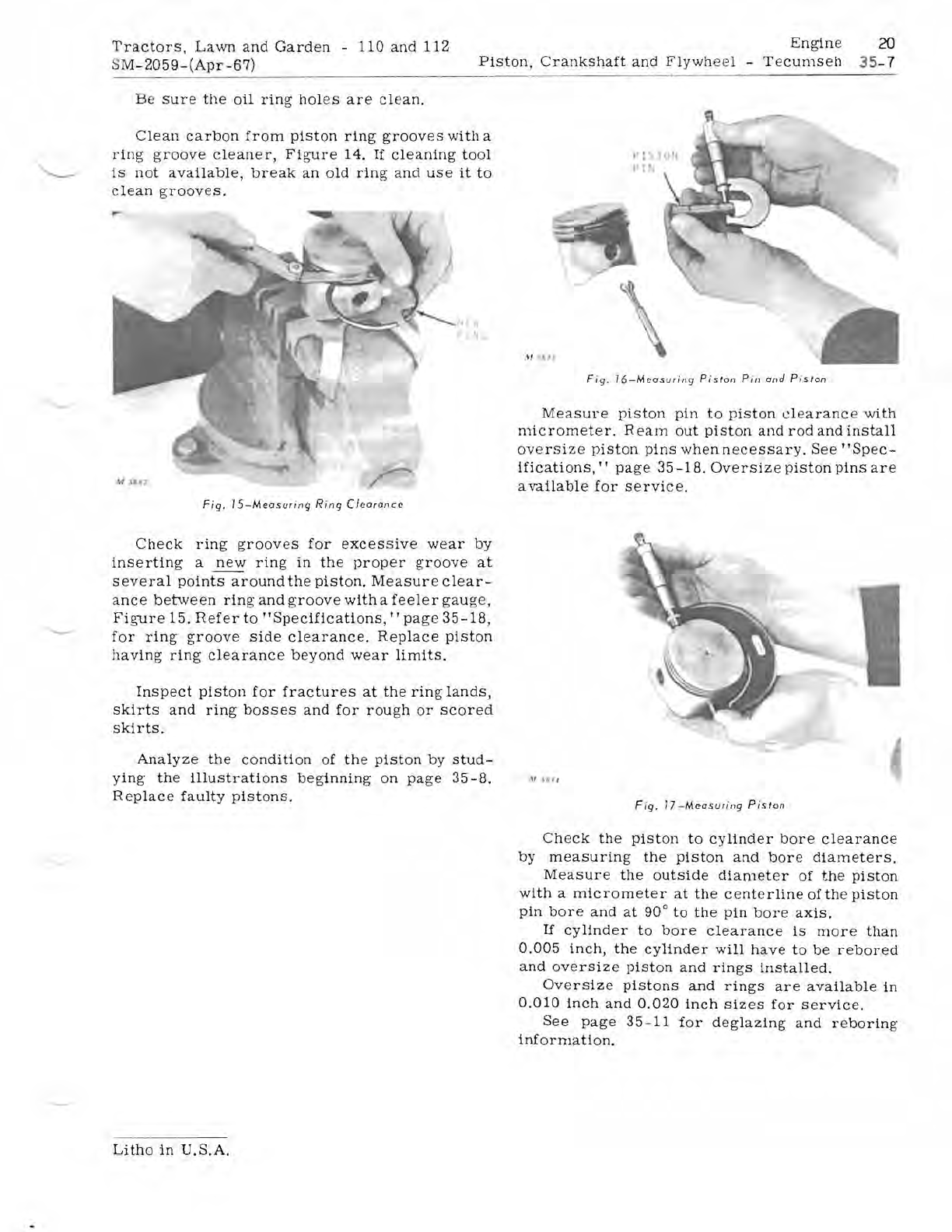

Fig.

17-Mcasuring

Piston

Check

the

piston

to

cylinder

bore

clearance

by

measuring

the

piston

and

bore

diameters.

Measure

the

outside

diameter

of

the

piston

with

a

micrometer

at

the

centerline

of

the

piston

pin

bore

and

at

90

0

to

the

pin

bore

axis.

If

cylinder

to

bore

clearance

is

more

than

0.005

inch,

the

cylinder

will

have

to

be

rebored

and

oversize

piston

and

rings

installed.

Oversize

pistons

and

rings

are

available

in

0.010

inch

and

0.020

inch

sizes

for

service.

See

page

35-11

for

deglazing

and

reboring

information.

Litho

in

U.S.A.