Tractors,

Lawn

and

Garden

-

110

3nd

112

Electrical

System

40

SM

-2059-

(Apr-67)

Ignition

System

10-

15

Co

il

polarity

is

important

because

incorrect

polarity

will

r e

quil'e

4000-

8080

volts

mOl"e

to

fire

th

e

spark

plug.

One

method

to

che

ck

po-

l

arity

is

to

connect

the

negative

lead

of

a

volt

meter

to

the

spark

plu£r

termin

'

ll.

Wi-:h

engine

running,

momentaril

y

touch

positive

volt-

m

eter

le

ad

to

a g'ood

ground.

Th

e

co

il

polarity

is

cor

-

rect

if

the

meter

reads

up

scale.

!\nothel"

method

is

to

hold

the

spark

p

lu

g-

high

tens

i

oa

wi

re

a

bout

1/ 8

inch

from

the

spa

rk

plug,

Insert

lea

d

po

int

of

a

wooden

pencil

in"

spark,

Figure

31.

Spark

should

flare

and

turn

orange

on

plug

side

of

pencil

lead

if

polarity

is

correct

. A

loss

of

eng

ine

powel'

is

also

noticed

when

the

co

il

poLlrity

is

incorr

ec

t.

Refer

to

illustrati

ons

in

Group

5

for

proper

el

ectrica

l

connections.

ADJUSTING

NE

U

TRAL-START

SWITCH

AND

BRAC

KET

Before

attempting

to

make

any

switch

01

'

bracket

adjustments,

check

the

neutral-start

bracket

for

ex

c

essive

l

ooseness

at

fork

pivot.

Also

c

heck

condition

of

dimple

on

und

erside

of

fo

rk.

Replace

bracket

if

necessary.

Continued

usage

of

the

tractor

s

hiIt

er

lever

will

cause

the

neutral-start

switch

to

wear

and

loosen,

making

switc

h

adjustment

n

ecessary.

Oc-

casionally,

a

neutral-start

switch

is

r

eplacedor

is

bypass-wired

even

though

a few

simple

ad-

justments

woule!

fix

it.

Before

replacing

a

switch,

follow

the

adj

us

tment

procedu

re

des

c

ri

bed

he

1'0

fOl"

110

and

112

Tra

ct

ors

.

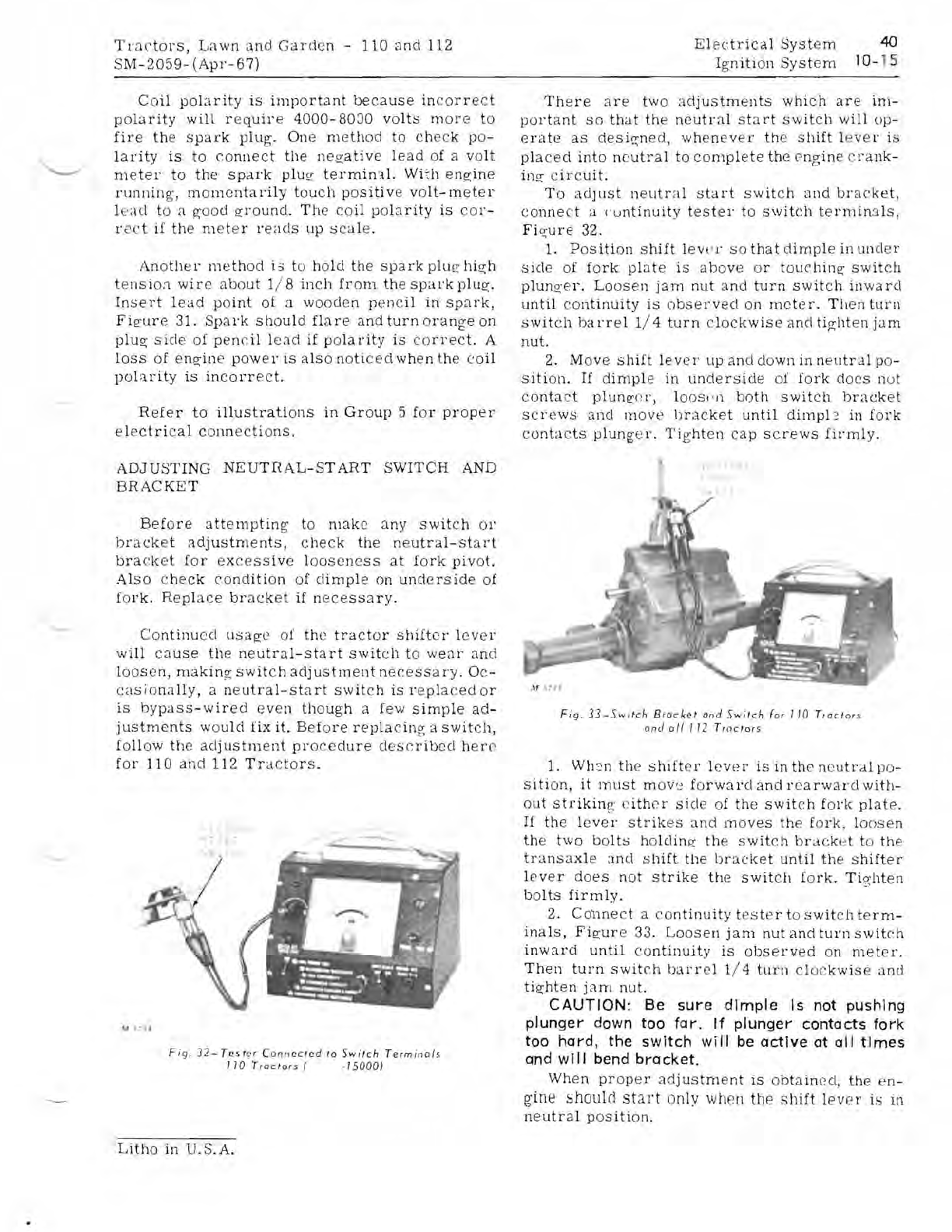

Fig,

32-

Te

s t

er

Conncc,cd

to

Switch

Ter

minals

110

Tr

octors

( ·

1500

0)

There

are

two

adjustments

whic

h

are

im-

portant

so

that

the

n

eut

r al

start

switch

will

op-

erate

as

designed,

whenever

the

shift

le

vel'

is

placed

into

nc:utral

to

complete

the

engine

crank

-

in

g-

circuit.

To

adjust

neutral

start

switch

3nd

bra

c

ket,

connect

a ('

untinu

ity

tester

to

switch

terminals,

FiQ;ure 32.

1.

Position

shift

l

evl

'

l'

so

that

dimple

in

und

e r

side

of

fork

plate

is

above

or

touching

switch

plung

·e

r.

Loosen

jam

nut

and

turn

switch

inward

until

continuity

is

observed

on

meter.

Th

en

turn

sw

it

ch

barrel

1/4

turn

c

lockwise

anc!

ti~hten

jam

nut.

2.

Mov

e

shift

lever

up

ancl

down

in

neutral

po

-

sition.

If

dimple

in

underside

of

fork

does

not

contact

plungc

!

r,

100sl'I1

both

swit

ch

bracket

screws

and

move

iJracket

until

dimpl2

in

lork

contacts

plung

e

r.

Tighten

cap

screws

firmly.

Fig,

33-Switch

B r

ocket

and

Switch

for

110

Traclors

and

0/1 T

12

Tractors

1. Wh:'n

the

shifter

l

ever

is

in

the

n

eutl

"

al

po-

Sition,

it

must

mov'~

forward

and

rearward

with-

out

strikin

g:

l'ithcr

side

of

the

switch

fork

plate.

If

the

l

ever

strikes

and

moves

the

fork

,

loosen

the

two

bolts

holding

the

switch

bracket

to

the

trans

ax

l e :

md

shift

the

bracke

t

until

the

shifter

l

ever

does

not

str

ik

e

the

switch

fork.

Ti

e.;hten

bolts

firmly.

2. C011l1ect a

continuity

tester

to

switch

term-

inals,

Figure

33.

Loosen

jam

nut

and

turn

switeh

inward

until

continuity

is

observed

on

meter.

Then

turn

switch

barrel

1/ 4

turn

clo

c

kwise

and

tighten

jam

nut.

CAUTION:

Be

sure

dimple

Is not pushing

plunger down too

for.

If

plunger contacts

fork

too hard, the switch

will

be

active

at all

times

and

will

bend

bracket.

When

proper

adjus

tm

ent

is

obtained,

the

en-

gine

should

start

only when

the

shift

lever

is

in

neutr

al

pOSition.

Litho

in

U.S.A.