60

Hydraulic

System

Tractors,

Lawn

and

Garden

-

110

and

112

5-6

General

Information

SM-2059-

(Apr-57)

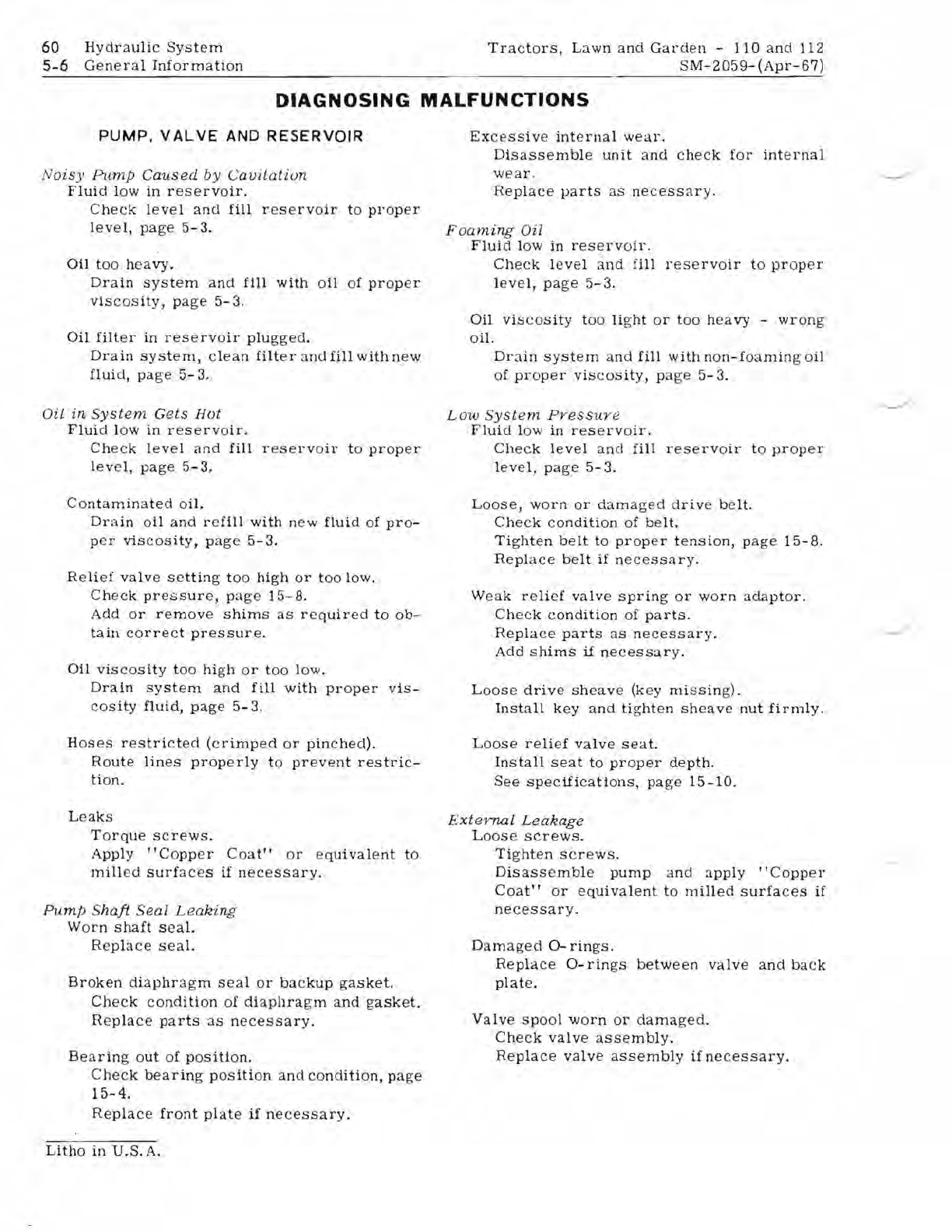

DIAGNOSING

MALFUNCTIONS

PUMP,

VALVE

AND

RESERVOIR

Noisy

Pnmp

Caused

by

Cavitatiun

Fluid

low

in

reservoir.

Check

level

and

fill

r e

servoir

to

proper

level,

page

5-3.

Oil

too

heavy.

Drain

system

and

fill

with

oil

of

proper

viscosity,

page

5-3.

Oil

filter

in

reservoir

plugged.

Drain

system,

clean

filter

and

fill

with

new

fluid,

page

5-

3.

Oil

in

System

Gets

Hot

Fluid

low

in

res

e

rvoir.

Check

level

and

fill

reservoir

to

proper

level,

page

5-3.

Contaminated

oil.

Drain

oil

and

refill

with

new

fluid

of

pro-

per

viscosity,

page

5-3.

Relief

valve

setting

too

high

or

too

low.

Check

pressure,

page

15-

8.

Add

or

remove

shims

as

required

to

ob-

tain

correct

pressure.

Oil

viscosity

too

high

or

too

low.

Drain

system

and

fill

with

proper

vis-

cosity

fluid,

page

5-3.

Hoses

restricted

(crimped

or

pinched).

Route

lines

properly

to

prevent

restric-

tion.

Leaks

Torque

screws.

Apply

"Copper

Coat"

or

equivalent

to

milled

surfaces

if

necessary.

Pump

Shaft

Seal

Leaking

Worn

shaft

seal.

Replace

seal.

Broken

diaphragm

seal

or

backup

gasket.

Check

condition

of

diaphragm

and

gasket.

Replace

parts

as

necessary.

Bearing

out

of

position.

Check

bearing

position

and

condition,

page

15-4.

Replace

front

plate

if

necessary.

Litho

in

U.S.A.

Excessive

internal

wear.

Disassemble

unit

and

check

for

internal

wear.

Replace

parts

as

necessary.

Foaming

Oil

Fluid

low in

reservoir

.

Check

level

and

fill

reservoir

to

proper

leve

1,

page

5-

3.

Oil

viscosity

too

light

or

too

hea

vy -

wrong

oil.

Drain

system

and

fill

with

non-foaming

oil

of

proper

viscosity,

page

5-

3.

Low

System

Pressure

Fluid

low in

reservoir.

Check

level

and

fill

reservoir

to

proper

level,

page

5-

3.

Loose,

worn

or

damaged

drive

belt.

Check

condition

of

belt.

Tighten

belt

to

proper

tension,

page

15-8.

Replace

belt

if

necessary.

Weak

relief

valve

spring

or

worn

adaptor.

Check

condition

of

parts.

Replace

parts

as

necessary.

Add

shims

if

necessary.

Loose

drive

sheave

(key

missing).

Install

key

and

tighten

sheave

nut

firmly.

Loose

relief

valve

seat.

Install

seat

to

proper

depth.

See

specifications,

page

15-10.

External

Leakage

Loose

screws.

Tighten

screws.

Disassemble

pump

and

apply

"Copper

Coat"

or

equivalent

to

milled

surfaces

if

necessary.

Damaged

O-rings.

Replace

O-rings

between

valve

and

back

plate.

Valve

spool

worn

or

damaged.

Check

valve

assembly.

Replace

valve

assembly

if

necessary.