20

Engine

Tractors,

Lawn

and

G

arde

n -

110

and

112

15-10

Piston.

Crankshaft

and

Flywheel

-

Kohler

SM-2059-(Apr

-67}

"

..

I

II',

1 'fI,

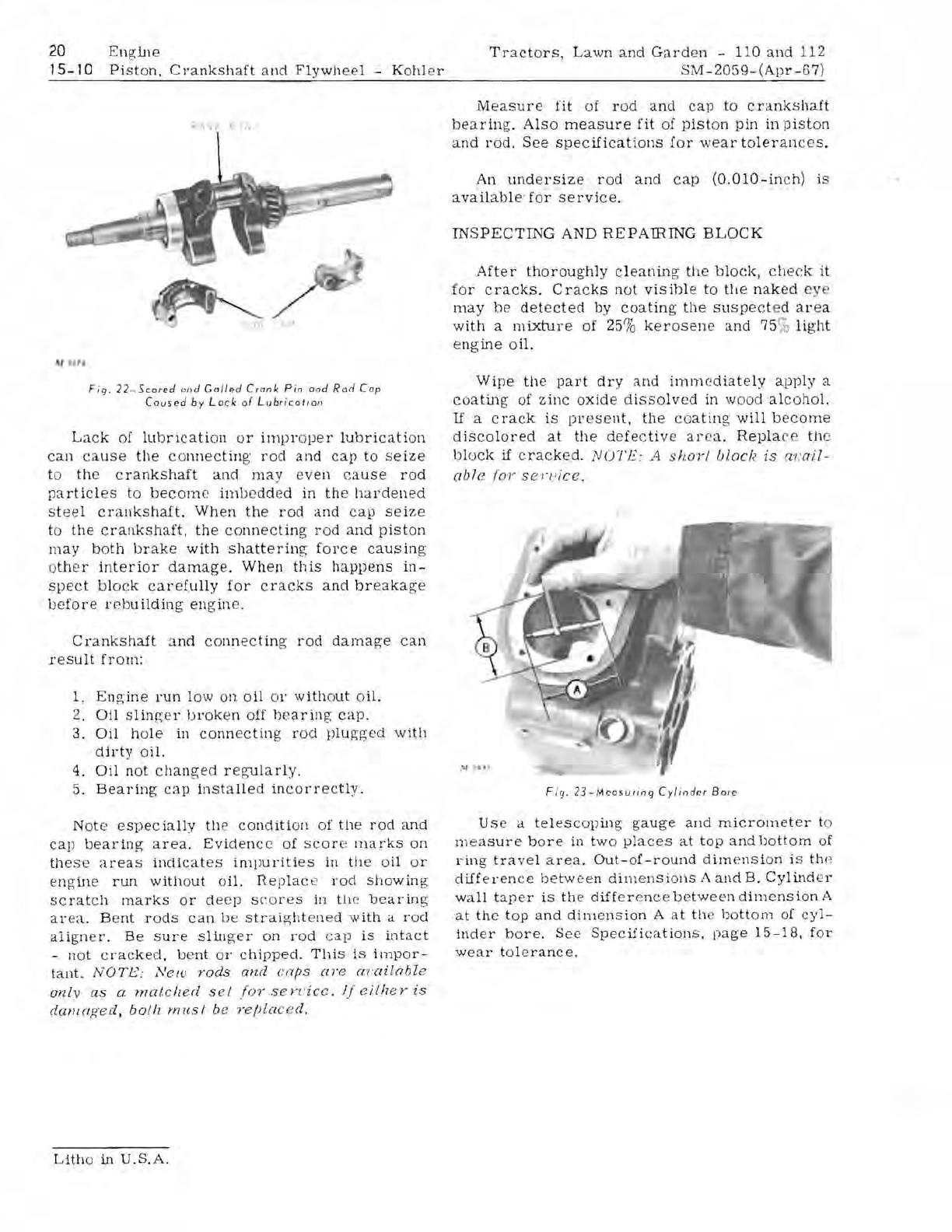

Fig.

22 -

Scared

ond

Galled

Crank

Pin

and

Rod

Cap

C

ause

d

by

Lo

ck

01

Lubricat

ion

Lack

of

lubrication

or

irnpr

oper

lubricati

on

ca

n

ca

use

the

connecting

rod

and

cap

to

seize

to

the

crankshaft

and

may

even

cause

rod

particles

to

become

imb

edded

in

th

e

hardened

steel

crankshaft.

When

the

rod

and

cap

seize

to

the

crankshaft,

the

connecting

rod

and

piston

may

both

brake

with

shattering

force

causing

o

th

er

interior

damage.

When

this

happens

in-

spect

block

carefully

for

cracks

and

breakage

be

fore

r

eb

uilding

engin

e.

Crankshaft

:md

conne

c

tin

g

rod

damage

can

result

from:

1.

Engine

run

low

on

oil

0

1'

w

ith

o

ut

oil.

2.

Oil

Slinger

broken

off

bearing

cap

.

3.

Oil

hole

in

conn

ecti

ng

r

od

plugged

with

dirty

oil.

4.

Oil

not

changed

regularly.

5.

Bearing

cap

installed

incorrectly.

Not

e

espec

ially

the

condition

of

the

rod

and

cap

bearing

area.

Eviden

ce

of

sco

r e

marks

on

these

areas

indicates

impurities

in

th

e o

il

or

eng

ine

run

without

oil.

TIeplac

e

rod

showin

g

scratch

marks

or

de

ep

scores

in tile

bearing

area.

Be

nt

rods

can

be

straight

en

ed

with

a

rod

aligner.

Be

Sure

slinger

on

rod

cap

is

intact

-

not

cracked,

bent

or

chipped.

This

is

impor-

tant.

NOTE:

Ne/U

rods

and

caps

are

cn-ailable

only

as

a

matched

sel

forsen

:

icc.

IjciLheris

dW)1

(l.£{e

d,

bolh

must

be ?'e/)laced.

Measure

fit

of

r

od

and

cap

to

crankshaft

bearing.

Also

measure

fit

of

piston

pin

in

piston

and

r

od

.

See

specifications

ior

wear

toleranc

es

.

An

undersize

rod

and

cap

(O

.OlO-in

ch)

is

available

·

for

service.

INSPECTING

AND

REPAffiING

BLOCK

After

thoroughly

cleaning

the

bloek,

check

it

for

cracks.

Cracks

not

visible

to

the

nak

ed

ey

may

be

det

e

cted

by

coating

the

suspect

ed

area

w

ith

a

mixture

of 25%

kerosen

e

and

75

%

light

e

ngine

oil.

Wipe

the

part

dry

and

imm

e

diately

apply

a

coating

of

zinc

oxide

dissolved

in

wood

alcohol.

U a c

rack

is

present.

th

e

coa

ting

will

become

discolored

at

the

defective

ar

e

a.

Repla

th

e

block

if

crac

ked

.

NOTE

; A

shoyl

bloch

is

av

ail-

abl

e

/01'

sen

'

ice.

Fig.

23-Mcasuring

Cyl

inder

Bore

Us

e a

telescoping

gauge

and

micrometer

to

m

ea

sure

b

ore

in

two

places

at

top

and

bottom

of

ring

tra

ve

l

ar

ea.

Out-oi-round

dimension

is t1w

difference

between

dimensions

A

and

B.

Cylind

e l'

wall

tap

er

is

the

differ

ence

between

dimension

A

at

th

e

top

and

dim

e

nsion

A

at

th

e

bottorn

of

cyl-

ind

er

bore.

See

SpeCifications.

page

15-18,

for

wear

tol

era

nce.

Lith

o

in

U.S.A.