60

Hydraulic

System

Tractors,

Lawn

and

Garden

-

110

and

112

5-2

General

Information

SM-2059-(Apr-67)

PRINCIPLE

OF

OPERATION

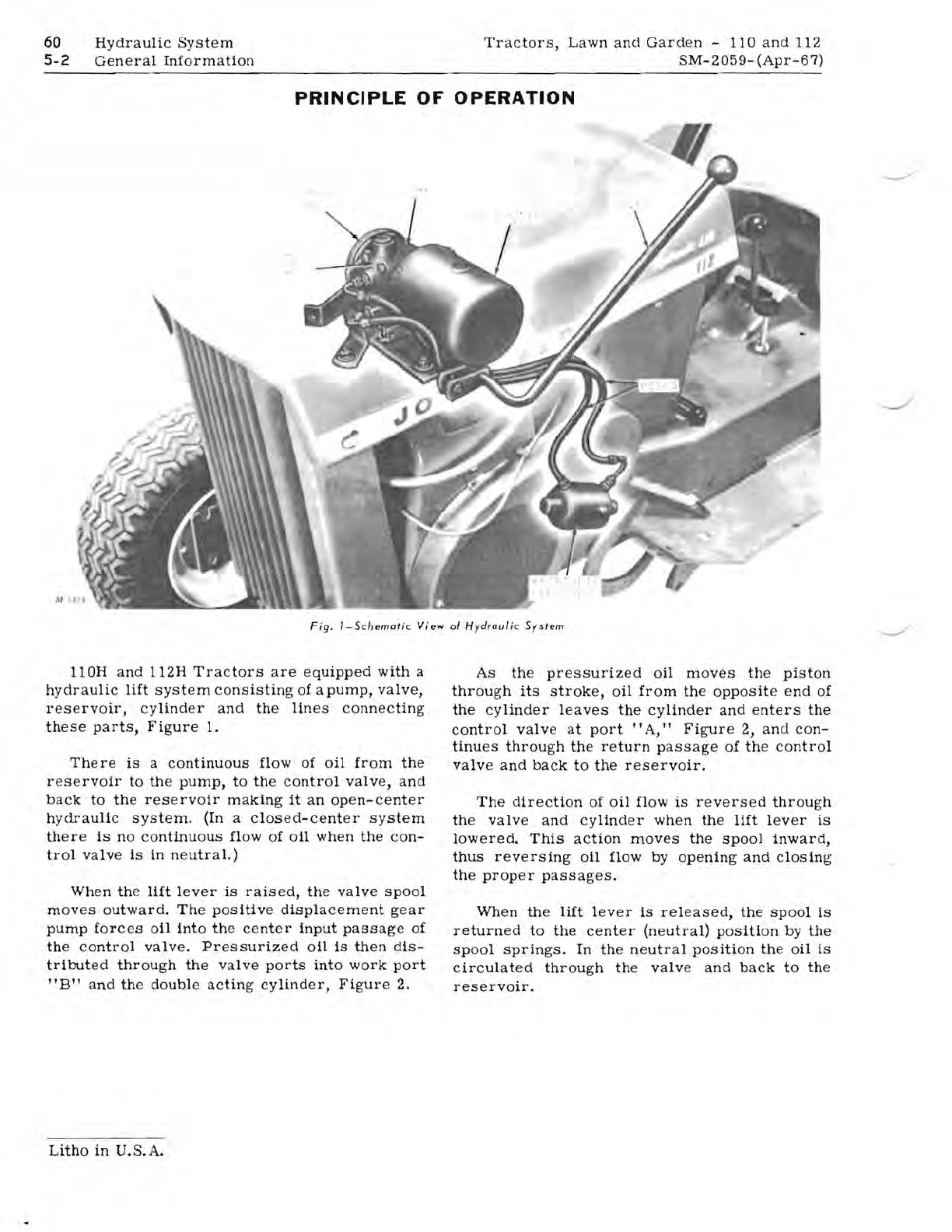

Fig.

I-Schemat

ic

View

01

Hydraulic

System

110H

and

112H

Tractors

are

equipped

with

a

hydraulic

lift

system

consisting

of

a

pump,

valve,

reservoir,

cylinder

and

the

lines

connecting

these

parts,

Figure

1.

The

re

is

a

continuous

flow

of

oil

from

the

reservoir

to

the

pump,

to

the

control

valve,

and

back

to

the

reservoir

making

it

an

open-center

hydraulic

system.

(In a

closed-center

system

there

is

no

continuous

flow

of

oil

when

the

con-

trol

valve

is

in

neutral.)

When

the

lift

lever

is

raised,

the

valve

spool

moves

outward.

The

positive

displacement

gear

pump

forces

oil

into

the

center

input

passage

of

the

control

valve.

Pressurized

oil

is

then

dis-

tributed

through

the

valve

ports

into

work

port

"B"

and

the

double

acting

cylinder,

Figure

2.

As

the

pressurized

oil

moves

the

piston

through

its

stroke,

oil

from

the

opposite

end

of

the

cylinder

leaves

the

cylinder

and

enters

the

control

valve

at

port

"A,"

Figure

2,

and

con-

tinues

through

the

return

passage

of

the

control

valve

and

back

to

the

reservoir.

The

direction

of

oil

flow

is

reversed

through

the

valve

and

cylinder

when

the

lift

lever

is

lowered.

This

action

moves

the

spool

inward,

thus

reversing

oil

flow

by

opening

and

closing

the

proper

passages.

When

the

lift

lever

is

released,

the

spool

is

returned

to

the

center

(neutral)

position

by

the

spool

springs.

In

the

neutral

position

the

oil

is

circulated

through

the

valve

and

back

to

the

reservoir.

Litho

in

U.S.A.