30

Fuel

System

Tract

o

rs,

Lawn

and

Garden

- 110 a

nd

112

10-2

Carburetor

-

110

Tract

or

SM-2059

-

(Apr-67)

Allow

parts

to

rem

ai

n

in

so

luti

on

from

one

to

two

hours

.

Then

remove

a

nd

rinse

with

fresh

clean

in

g

so

lvent.

Dry

with

compressed

a

ir,

mak-

ing

sure

all

hole

s

are

open

and

free

of

carb

on

and

di

rt.

Never

u

se

rags

or

waste

paper

to

dry

the

parts.

Any

lint

may

plug

je

ts

of

channels

and

aff

e

ct

operating

efficiency

of

carburetor.

CAUTION:

Never

use

compressed

aIr

to

clean

a

completely

assembled

carburetor.

To do

so

may

cause

the

float

to

collapse.

INSPECTING

CARBURETOR

Insp

ect

fl

oa

t

valve

to

be

sur

e

valve

seat

ma-

terial

or

other

debris

is

not

adhering

to

tapered

surface

of

valve.

If

any

mat

e

rial

appears

on

tap

ere

d

surface,

replace

floa

t

valve

and

valve

seat

assembly.

Inspect

seat

assembly

for

wear

or

o

ther

dam-

age.

If

valve

seat

is

damaged

in

any

way,

re-

place

valve

seat

assembly

and

flo

at

valve.

Valves

and

seats

are

available

only

as

match-

ed

sets

and

should

never

be

interchang

ed.

For

a

positive

leak

test,

imm

e

rse

the

float

in

hot

wa

ter.

Any

leak

can

be

det

ec

ted

at

once

by

air

bubbles

escaping

from

the

float.

Do

not

at-

tempt

to

repair

the

float

if

it

leaks.

Replace

it.

Check

float

shaft

and

replace

if

worn.

Inspect

tapered

ends

of

needle

s .

If

a

ring

has

been

cut

in

the

tapered

surface

of e

ither

because

th

e

needle

has

been

turned

too

tightly

against

the

s

ea

t,

replace

the

needl

e.

The

seats

for

the

high

speed

and

idle

mixture

adjusting

n

ee

dles

are

an

inte

g

ral

part

of

the

carburetor

body

casting

and

ther

efo

re

cannot

be

remov

ed

or

replaced.

Insp

e

ct

carburetor

body

casting

and

fuel

bowl

for

cracks

or

damaged

seating

surface.

Examine

threaded

holes

for

damaged

threads.

Check

thr

o

ttle

and

choke

shaft

bearing

areas

in

carbu-

retor

body

for

wear.

Replace

if

worn

or

damaged

.

Inspect

jets

for

damaged

or

plug

ge

d

holes.

Replace

if

damaged.

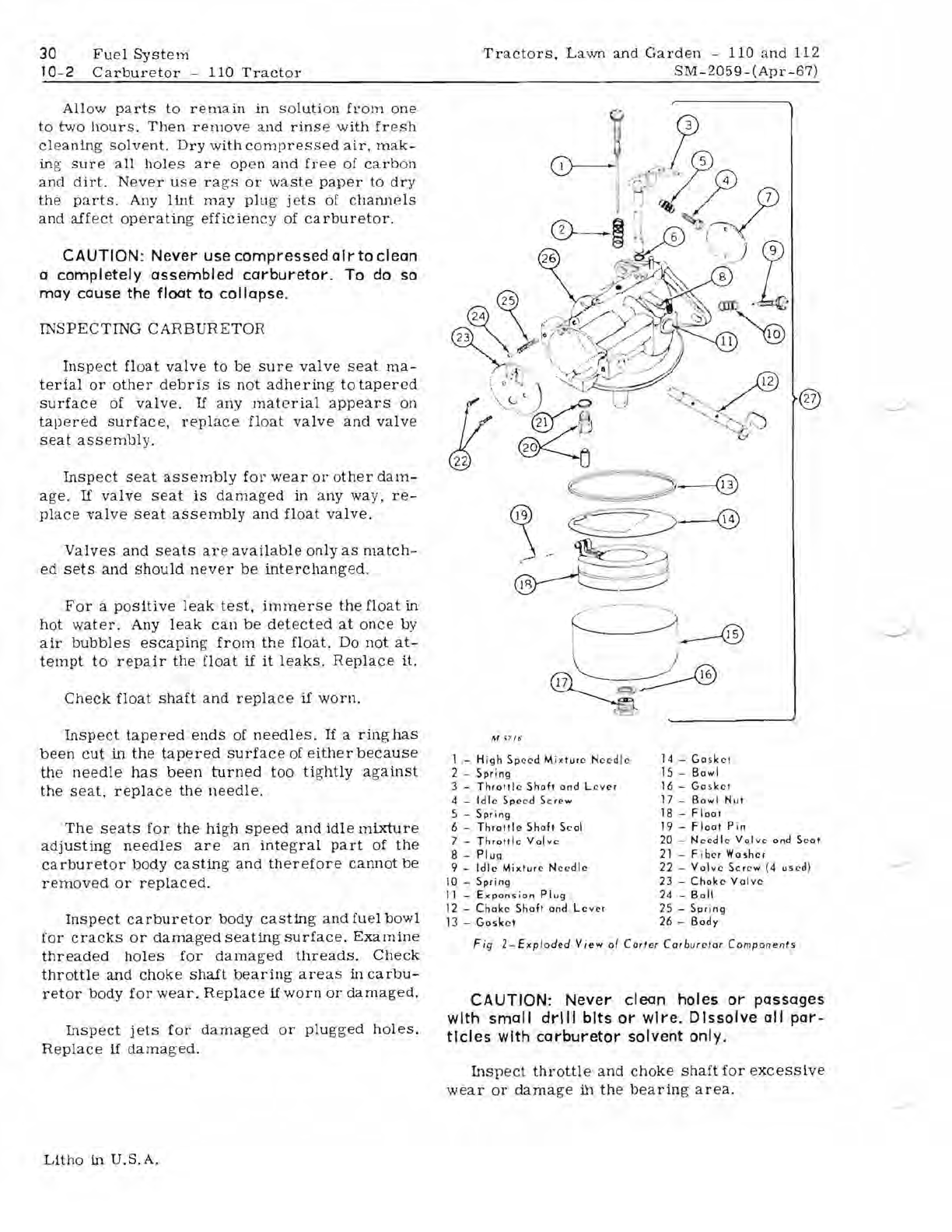

M

,,7ft;

-

High

Sp

ee

d

Mixture

Needle

14

-

Ga

ske

t

2 -

Spring

15

-

Bowl

3 -

Throttle

Shaft

and

Lever

16

-

Gesket

4 -

Idle

Speed

Screw

17

-

Bawl

Nut

5 -

Spring

18 -

Float

6 -

Throttle

Shaft

Se

al

19

-

Float

Pin

7 -

Throttle

Valve

20

-

Needl

e

Valve

and

Scat

8 -

Plug

21

- F i

ber

Washer

9 -

Idle

M

ixtur

e

Ne

e

dle

22

-

Valve

Scr

e w

(4

us

ed)

10 -

Spring

23

-

Choke

Valv

e

11

-

Expansion

Plug

24

-

Boll

12

-

Choke

Shaft

and

Lever

25

-

Spring

13 -

Gasket

26

-

Body

Fig

.

2-Exploded

View

of

Corter

Carburetor

Components

CAUTION:

Never

clean

holes

or

passages

with

small

drill

bits

or

wire.

Dissolve

all

par-

ticles

with

carburetor

solvent

only.

Inspect

throttle

and

choke

shaft

for

excessive

wear

or

damage

ill

the

b

ea

rin

g

area.

Litho

in

U.S.A.