60

Hydraulic

System

Tractors,

Lawn

and

Garden

-

110

and

112

10-4

Control

Valve

SM-2059-

(Apr-57)

INSPECTION

VAL

VE

HOUSING

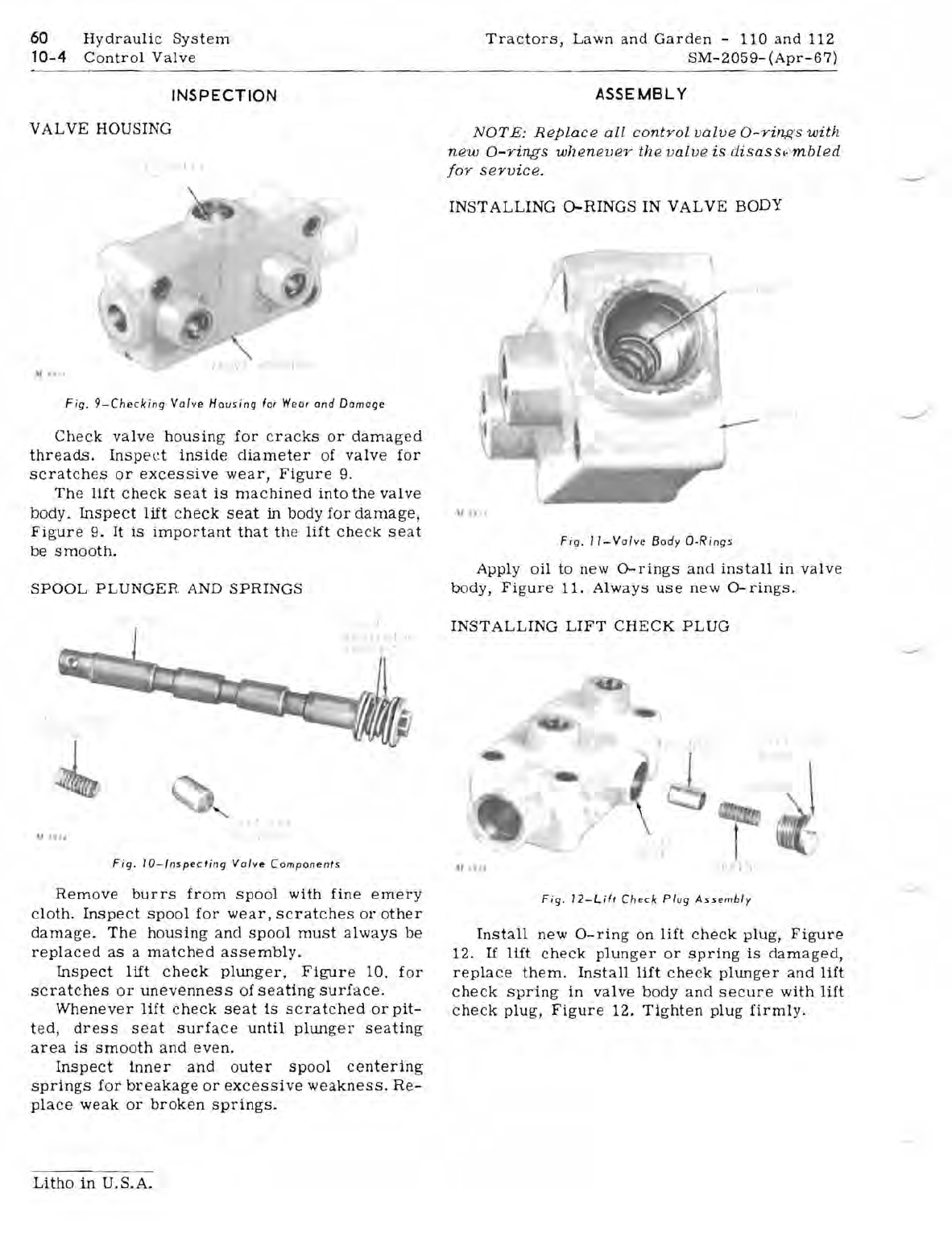

Fig.

9-Checking

Valve

Housing

fa,

Weo

,

and

Damage

Check

valve

housin

g

for

cracks

or

damaged

threads.

Inspect

inside

diameter

of

valve

for

scratches

or

excessive

wear,

Figure

9.

The

lift

check

seat

is

machined

into

the

valve

body.

Inspect

lift

check

seat

in

body

for

damage,

Figure

9.

It

is

important

that

the

lift

che

ck

seat

be

smooth.

SPOOL

PLUNGER

AND

SPRINGS

Fig

.

IO-lnspecting

Valvt!

Components

Remove

burrs

from

spool

with

fine

emery

cloth.

Inspect

spool

for

wear,

scratches

or

other

damage.

The

housing

and

spool

must

always

be

replaced

as

a

matched

assembly.

Inspect

lift

check

pitll1ger,

Figure

10,

for

scratches

or

unevenness

of

seating

surface

.

Whenever

lift

check

seat

is

scratched

or

pit-

ted,

dress

seat

surface

until

plunger

seating

area

is

smooth

and

even.

Inspect

inner

and

outer

spool

centering

springs

for

breakage

or

excessive

weakness.

Re-

place

weak

or

broken

springs.

Litho

in

U.S.A.

ASSEMBLY

NOTE:

Replace

all

control

valve

O-ri/1.{!,'S

with

new

a-rings

whenever

the

valve

is

disasst

:

mbled

jor

service

.

INSTALLING

O-RINGS

IN

VALVE

BODY

"

\l

h'

Fig.

II-Valve

Body

D-R

i

ngs

Apply

oil

to

new

O-rings

and

install

in

valve

body,

Figure

11.

Always

use

new

O-rings.

INSTALLING

LIFT

CHECK

PLUG

"

..

' f

Fig.

12-Lift

Check

Plug

Assembly

Install

new

O-ring

on

lift

check

plug,

Figure

12.

If

lift

check

plunger

or

spring

is

damaged,

replace

them.

Install

lift

check

plunger

and

lift

check

spring

in

valve

body

and

secure

with

lift

check

plug

,

Figure

12.

Tighten

plug

firmly

.