20

Tractors,

L

aw

n

and

Garden

- 110

and

112

Engine

SM-2059-

(Apr

-67)

Piston,

Crankshaft

and

Flywheel

-

Kohler

1

5-

11

DEGLAZING

CYLINDER

BORE

Deglazing

is

not

intended

to

remove

any

appreciable

amount

of

metal

from

the

bore,

but

rather

to

clean

up

and

provide

the

proper

sur-

face.

A

propel'

bore

surface

feels

smooth

but

ha

s

a

cross-hatch

pattern

of

rnicro-scratcheswhich

can

be

seen.

This

finish

w

ill

allow

the

new

rings

to

seat

or

run-in

properly.

This

finish

also

r

e-

tains

a

small

film

of o il

to

provide

ring

'

lubri-

ca

ti

on

for

the

ring

surface

and

prevents

scoring.

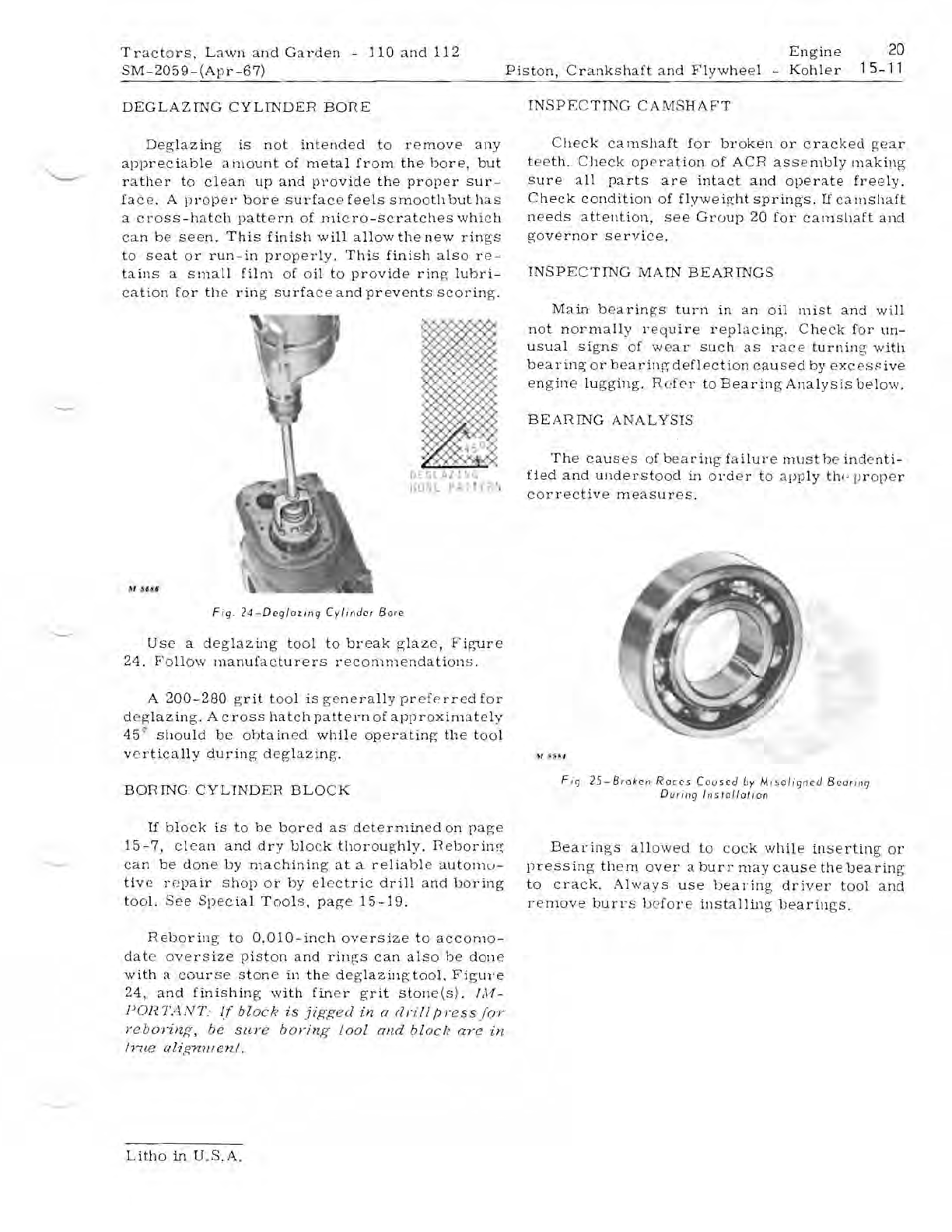

Fig.

24-Dcg/azing

Cylinder

Bore

Use

a

deglazing

tool

to

break

glaze,

Figure

24.

Follow

manufacturers

recommendations.

A

200-280

grit

tool

is

ge

nerally

preferred

for

degl

az

ing. A

cross

hatch

pattem

of

apprOXimately

45

~

should

be

obtai

n

ed

while

operating

the

to

ol

ve

rtically

during

deglazing.

BORING

CYLINDER

BLOCK

If

block

is

to

be

bored

as

determined

On

page

15-7,

c

lean

and

dry

block

thoroughly.

neborinr;

can

be

done

by

machining

at

a

reliable

automu-

tive

repair

shop

or

by

el

e

ctric

drill

and

boring

tool.

See

Specia

l

Tools,

page

15-19.

Reboring

to

0.010-inch

oversize

to

accomo-

date

overSize

piston

and

rin~s

can

also

be

done

with

a

course

stone

in

the

deglazing

tool.

Figure

24,

and

finishing

w

ith

finer

grit

StOlle(S). 1;\1-

POR1ANT:

If

block

is

jif(f(ed

in

(/

dr

i

l1

press/o/"

reborinf{,

be

sure

boring

tool

alld

block

are

in

true

ali.frmnenl.

INSPECTING

CAMSHAFT

Check

camshaft

for

broken

or

c

rack

ed

gear

teeth.

Check

ope

ration

of

ACR

assembly

making

sure

all

parts

are

intact

and

operate

freely.

Check

condition

of

flywei

gh

t

springs.

If

ca

mshaft

needs

attention,

see

Gruup

20

for

camshaft

and

governor

service.

INSPE

CTING

MAIN

BEARINGS

Main

bearin

gs

turn

in

an

oil

mist

and

will

not

normally

require

replaCing.

Check

for

un-

usual

signs

of

we

ar

such

as

race

turnin

g

with

bea

ring

or

bea

rinr;

deflection

caused

by

excess

ive

eng

ine lu

gg

ing. Re

fer

to

Bearing

Analysis

below.

BEARING

ANALYSIS

The

ca

us

es

of

bearing

failure

must

be in

den

ti-

fied

and

understood

in

order

to

app

ly

th

(l

proper

corrective

measures.

Fig

.

25-Brokcn

Ra

c

es

Caused

by

Misaligned

Beurillg

D

uring

In

stollation

Bearing

's

allowed

to

cock

while

in

serting

or

preS

Sing

th

em

over

a

burr

may

cause

the

bearing

to

crack.

Always

us

e

bearing

driver

tool

and

remove

burrs

be

fore

installing

bearings.

Litho

in

U.S.A.