'

1

1;);1-

\Apr

-0

I )

SCREWS

AND

CARR

I

ER

K

WASHERS

(BORED

HOLES

)

~

d6c

BEARING

:::::

RACE

o

o

d

~===:r=

~_,

_

~~:::~R

",

:::t=IIII

\

::D

?0

1

~

EARINC

__

BEVEL PINION BEAR I G

i'ACER CAP

SCREWS

AND

__

"

a--

,

--DR

IVE BLOCK

LOCK

WASHERS

"XLE

AND

IER

,"

lU'

PIN

I

ON

(1

APPED

HOLE

F

ig,

21-Dj(ferenl

iol

A

ssembly

- TlO Tr

oc/

or.

( .3571)

toe

';

'

~l

A'

W

~~,~

lR

:. ',S 'I

I~,

II

It

,

PI'.

ASS

EMBLY

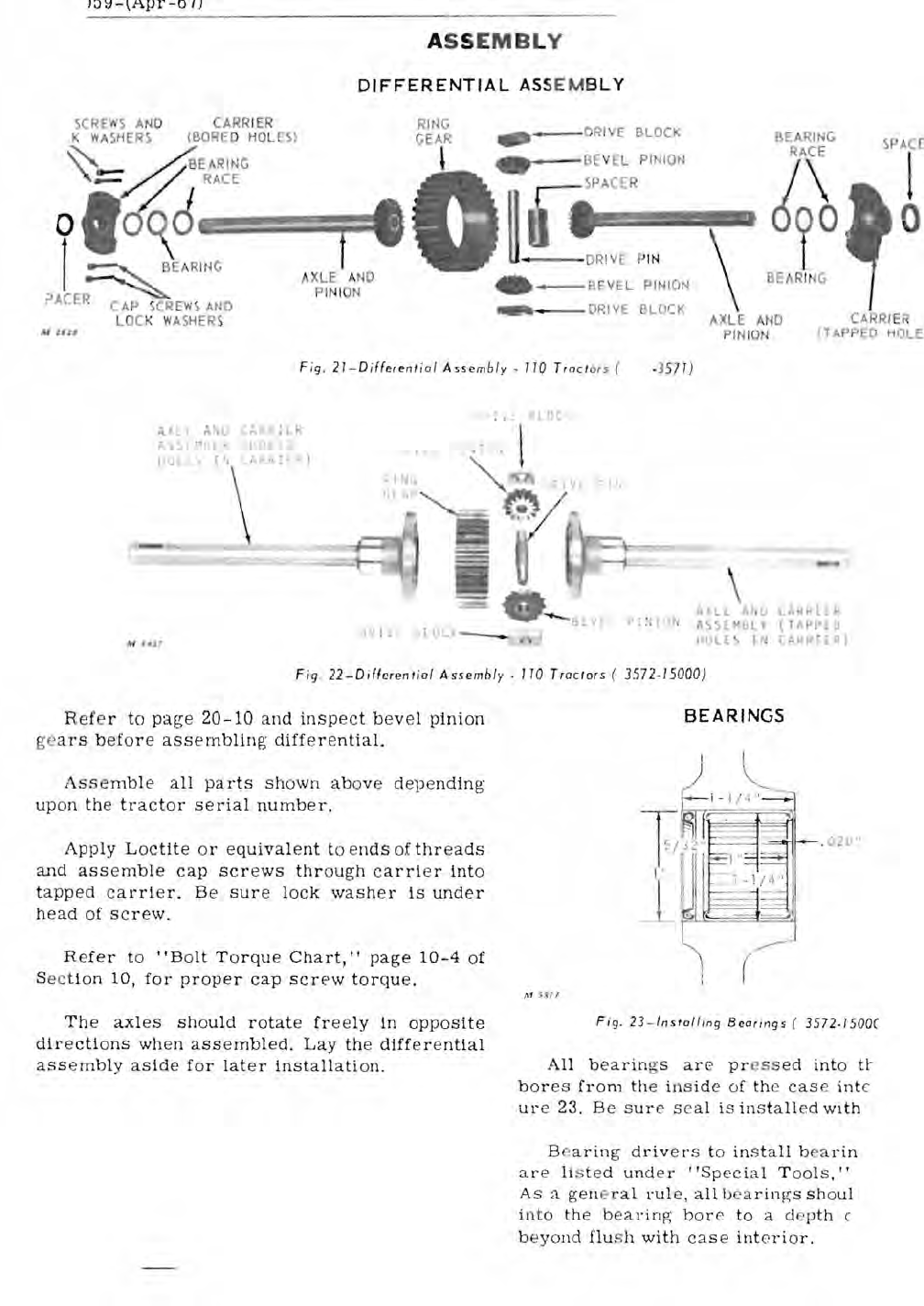

DIFFERENTIAL

AS

SEM

BLY

RING

_DRIV

E BLOCK

GEAR

BEARING

SPACE

••

-.-

, - -

mEL

"",0"

i\

lC

-

')

M

SlJ'

F

ig

22-

D

if/c

r

enliol

Ass

embly,

110

Tro

c

lors

(

Ref

e r

to

page

20-10

and

inspect

bev

el

pinion

ge

ars

bef

or e

assembling

differential.

Ass

em

bl

e

all

parts

shown

above

dep

e

nding

up

on

th

e

tr

actor

se

rial

number,

Apply

Loctite

or

equivalen

t to

en

ds

of

threads

and

assemble

cap

s c r

ews

thr

oug

h

ca

rri

e r into

tapped

carr

i

er.

Be

sure

l

oc

k

washe

r

is

under

head

of

screw.

Refer

to

"B

o

lt

T o

rqu

e

Chart,"

page

10-4

of

Sect i

on

10,

for

prope

r

cap

screw

torque.

The

axles

should

r

otate

fr

ee

ly

in

oPPosi

te

dir

ec

tions

when

assembled.

Lay

th

e

differential

assembly

aside

fo

r

later

installati

on.

"

Ll

A"J

l.:'KHI£R

P:~IO~ S.l~bL

(TAPPlO

H

L[

I i

(A~R

rR)

3572

-

15000)

BEARINGS

l--

-

-j

- 9

1r-

-,

02

(j

"

(

Fi

g.

23-l

n

sloll;og

Beorings

(

3572

. 1500C

All

b

ear

ings

are

pr

ess

ed

into

U-

bor

es

from

the

in

si

de

of

th

e

case

inte

ur

e 23.

Be

sure

sea

l

is

inst

alled

with

Baring

drivers

to

install

bea

rin

a r e

li

s

ted

under

"Special

T

oo

l

s,

"

As

a

ge

ne

ral

rul

e,

all

be

aring

s

sh

o

ul

into

th

e

bearing

bore

to

a de

pth

(

b

eyond

flu

s h

with

case

int

er

io

r.