Tractors.

Lawn

and

Gard

en

- 110

and

112

Engine

20

SM-2059

-

(Apr-67)

Piston,

Crankshaft

and

Flywheel

- Ko

hler

15-15

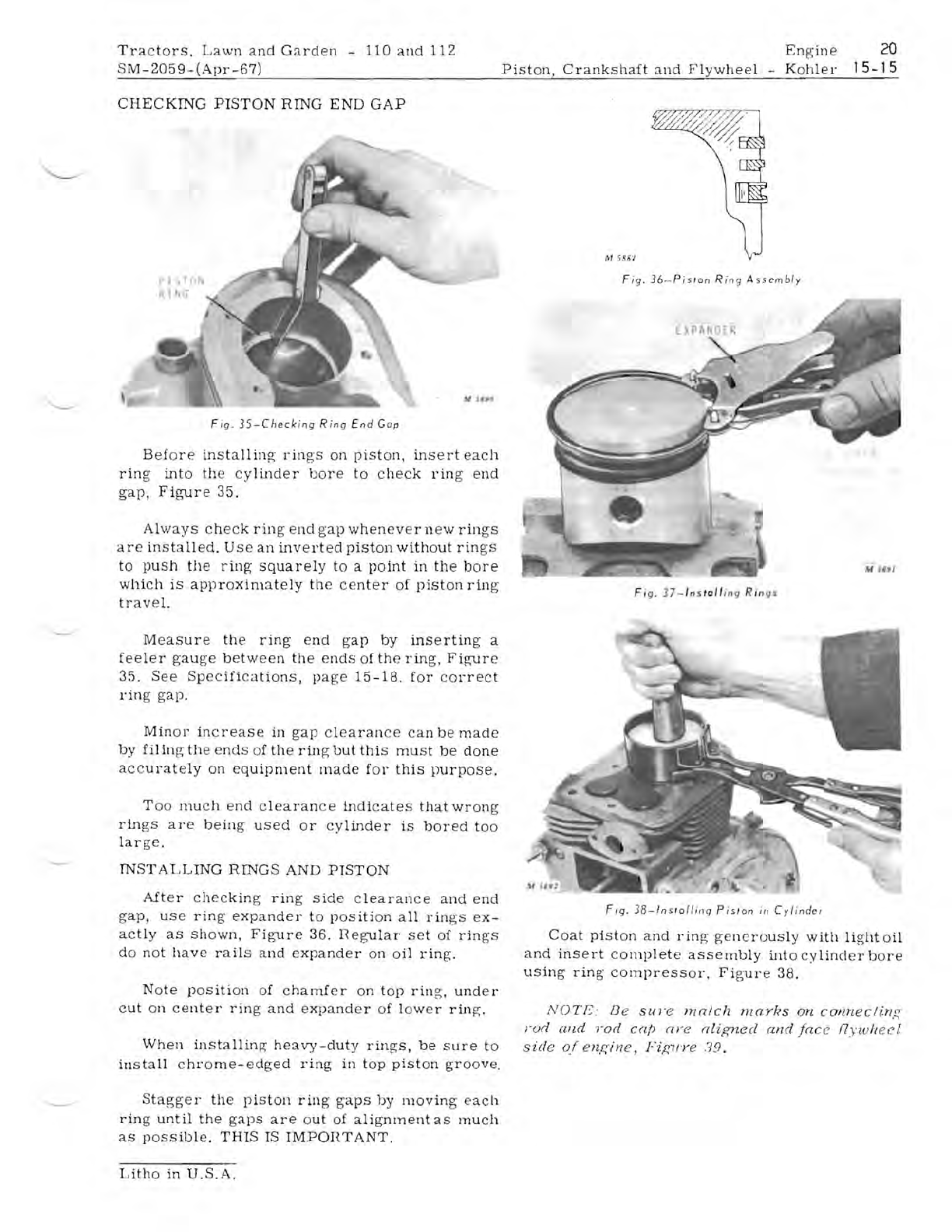

CHECKING

PISTON

RING

END

GAP

PI,

T

",

I '.I

..

F

ig.

35-Checking

Ring

En

d G

ap

Bef

or e

installing

rin

g's

on

piston,

ins

e

rt

each

ring

into

the

cyl

inder

bore

to

check

ring

end

gap,

Figure

35.

Always

check

ring

end

gap

whenever

new

rings

a

re

installed.

Use

an

invert

ed

piston

with

o

ut

rings

to

push

the

ring

squarely

to

a

point

in

the

bore

which

is

approximately

th

e

ce

nter

of

piston

ring

travel.

M

eas

ure

th

e

ring

end

gap

by

inserting

a

feeler

gauge

between

the

ends

of

the

ring,

Figure

35.

See

Specifications,

page

15-18.

for

co

rrect

ring

ga

p.

Minor

increase

in

gap

c

learan

ce ca

n

be

made

by

hi

ing

the

ends

of

the

ring

but

this

must

be

done

accurately

on

equipment

made

for

this

purpose.

Too

much

e

nd

clearan

ce

indicates

that

wrong

rings

are

bein

g

used

or

cylinder

is

bored

too

lar

ge

.

TNSTALLING

RTNGS AND

PISTON

After

checking

ring

Side

clearance

and

end

gap,

us

e

rin

g

expander

to

pOSition

all

ring

's

ex

-

actly

as

shown,

Figure

36.

Regular

set

of

rin

gs

do

not

have

rails

and

expander

on

oil

ring.

Note

position

of

chamfer

on

top

rin

g,

under

cut

on

center

rin

g

and

expander

of

lower

ring.

When

installing

heavy-duty

rings,

be

sure

to

install

chrome-

edge

d

ring

in

top

piston

groove.

Stagger

the

piston

ring

gaps

by

moving e

ach

ring

until

the

gaps

are

o

ut

of

alignment

as

much

as

possibl

e.

THIS

IS

IMPORTANT.

Litho

in

U.S

.

A.

Fi

g.

36-Pislon

R

ing

A

sscm

bly

F

i9.

J7 - Ins

loll

ing

Ri

ng.

F

ig.

38-lnstoll;n9

Piston

i"

Cylindcr

Coat

piston

and

rin

g

generously

with

li

gh

t

oil

and

insert

co

mplete

assembly

into

cylinder

bore

using

ring

'

compressor.

Figure

38.

NOIE·

l3e

sure

malch

marks

on

conneclin::;

ro

d

alld

rod

cap

{/

re

alif{ned

and

face

r7yw/teC'l

side

of

enr:;ine,

Fif!,7lye

.99

.